PVC/UPVC Wood Plastic Composite WPC Hollow Door Board Panel Making Machine

Ningbo Easyget Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

double face coatingMachine detailed pictures

double face coatingMachine detailed pictures PVC WPC door panel machine

(1)Twin conical screw extruder

According to different size of product, equip different model extruder.SJSZ-80/156,SJSZ-92/188 etc.

Siemens motor

ABB,Omron.Siemens electric component.

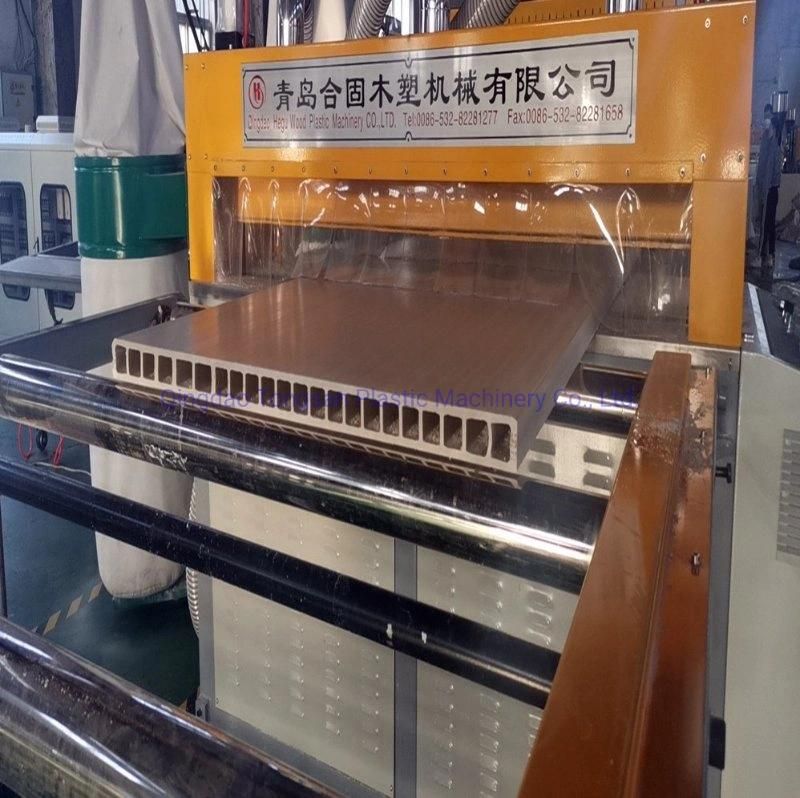

(2)Door panel mould

You can use one extrusion line to produce different size product by changing the mould.

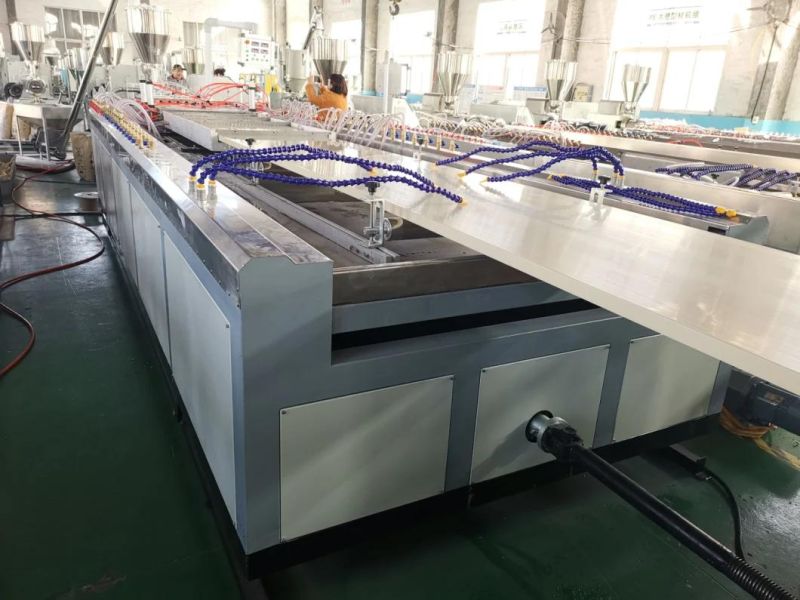

(3)Calibrating table

Equipped with vacuum pump and water pump. the part which connect with water is made of 304 stainless steel.

(4)Haul off machine

(5)Door board cutting machine

Can cut the door board in any length.

PVC WPC door frame profile making machine

PVC WPC door frame profile making machine  The PVC WPC profile extrusion line is suitable for producing hollow or solid PVC WPC foaming profiles. This profiles have advantages of fireproof, waterproof, anticaustic, moisture proof, moth proof, mildew proof, non-toxic and environmentally friendly. The profiles are widely used in the fields of interior decoration, furniture making, such as door frame, skirting, photo frame, plastic door and window profiles.Auxilary machine for making PVC WPC door panel

The PVC WPC profile extrusion line is suitable for producing hollow or solid PVC WPC foaming profiles. This profiles have advantages of fireproof, waterproof, anticaustic, moisture proof, moth proof, mildew proof, non-toxic and environmentally friendly. The profiles are widely used in the fields of interior decoration, furniture making, such as door frame, skirting, photo frame, plastic door and window profiles.Auxilary machine for making PVC WPC door panel

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23