PVC Foam Board Extrusion Machine Line with CE and ISO9001

Ningbo Zhaoke Int'l Imp. & Exp. Corp / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJSZ65x132 Customized Customized Condition New Inverter ABB Control System PLC Control System Contactor Schneider Components Simens Operator 2-3person /Shift Warranty 12monthes Machine Color as Request Raw Material PVC Powder Extruder Type Twin Screw Extruder Screw Material 38crmoaia Transport Package PE Film and Wooden Package Specification CE ISO9001 Trademark SUKE Origin Qingdao, China HS Code 847780000 Production Capacity 50sets/YearProduct Description

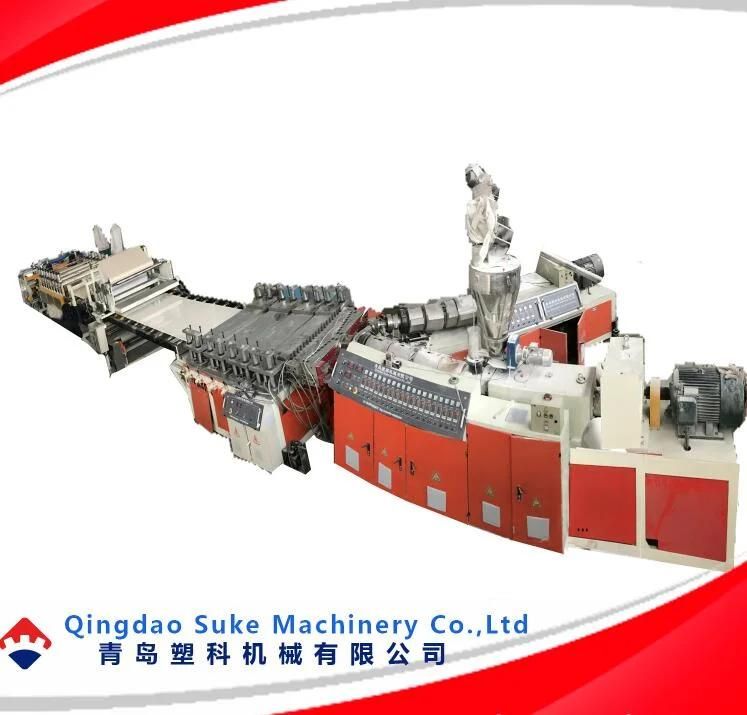

PVC Foam Board Extrusion Line Machine

Introduction:

Our PVC Foam Board Production Line equipped with SJSZ 80x156 twin screw extruder is best choice. This Foam Board Production Line has high output as well as low power consumption, but it is easier to operate and needs less maintenance after long time running.

Main Applications of Foam Board:

Transportation: Such as steamship, airplane, carriage, train compartment, roof shed, case core layer, inner upholster, etc.

Architecture: Such as building wall board, decoration board, housing, office, public building interlayer, commercial decoration shelf, non-dust room board ceiling plate, etc.

Industry: Such as chemical industry, thermoforming, for refrigerator, for temperature keeping for environment protection, etc.

Others: Such as mould plate, sports equipment, breeding equipment, seashore wet-proof facility, water-fast material, art material, various interlayer, etc.

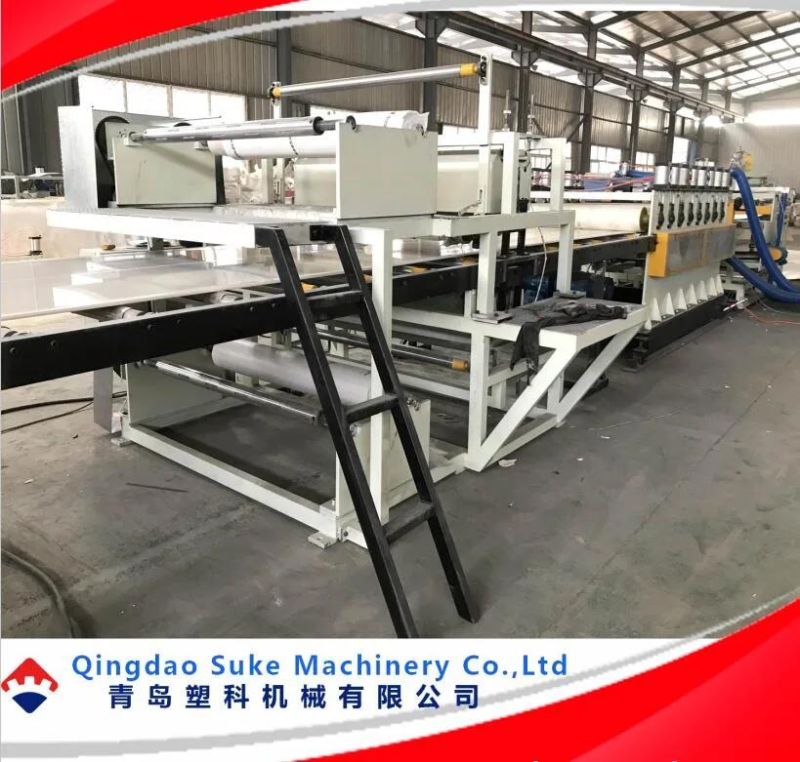

Equipment List:

1. Twin Screw Extruder

2. Extrusion Mold

3. Shapping Machine

4. Haul-off and Cutting Machine

5. Stacker

Auxiliary Machines:

1. SWP450 Crusher

2. 300/600 Mixer

3. SMP400 Miller

Our PVC Foam Board Extrusion line Machine is good in quality and competitive in price. We manufacture this line under the brand name "SUKE", and also supply OEM, ODM service according to your requirement.

If you want more details about this PVC Foam Board Production Line, please contact us.

| Model | Screw | Total Power (KW) | Output (Kg/h) |

| SKFB-1 | SJSZ 45/90 | 39. |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23