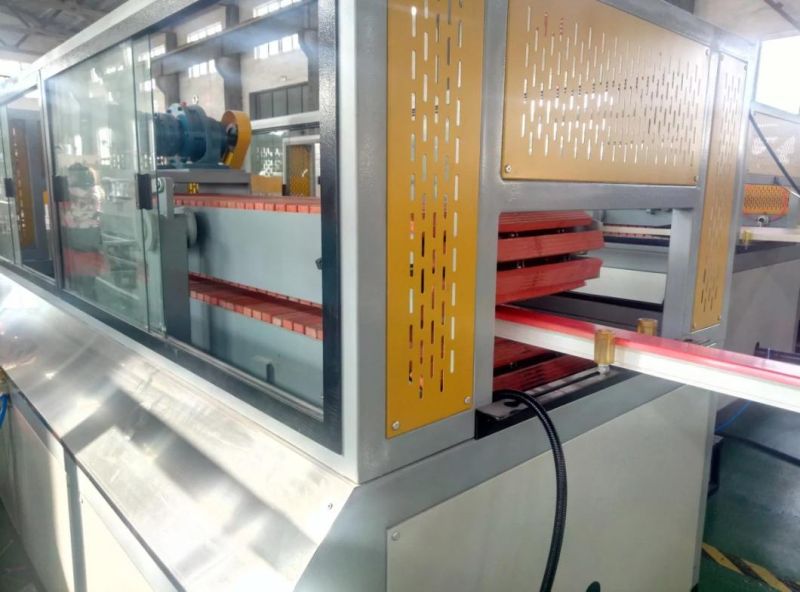

PVC UPVC Window Profile Frame Manufacturer Machine Window Manufacturing Equipment

Ningbo Easyget Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

According to different size of product, equipped with differnt model extruder. SJSZ-51/105, SJSZ-55/110,SJSZ-65/132,SJSZ-80/156

Motor brand:Siemens

Electric component:ABB,Omorn,Siemens

Heating circle:ceramics heating circle.

(2)PVC/UPVC mould

material: 3Cr17, tempering HRC28-32, ensure anti-rust, hardness and service life

Calibrator size: 240mm or 320mm

Quantity of calibrator section:1 or 2 or 3 or 4 sets according to product size shape

Water tank length: 2000mm or 4000mm, fiber glass board, accessories are made of stainless steel

(3)Calibrating table

(3)Calibrating table According to the product size, the calibrating table can be designed in differnet length, 4m/6m/8m etc. The part which connect with water is made of 304 stainless steel.

(4)Haul off and cutting machine.

Equipped with dust collection device

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23