Corn Flakes Chips Breakfast Cereals Kurkure Cheetos Extruder Making Machine Processing ...

Jiangsu Itech Labels Technology Co., Ltd. / 2022-07-04

- Processing Material:Stainless Steel

- Application:Pet Food, Corn Flakes Breakfast Cereals Production Plant

- Customized:Customized

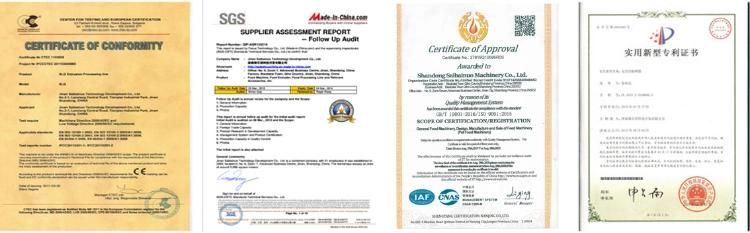

- Certification:CE, ISO9001

- Power Source:Electric

- Automatic Grade:Automatic

=== Base Info ===

- Model NO.:SLG-65, SLG-70, SLG-85, SLG-95, SLG-120,

- Capacity:150kg,H, 300kg,H, 600kg,H, 1.5t,H

- Machine Material:Stainless Steel

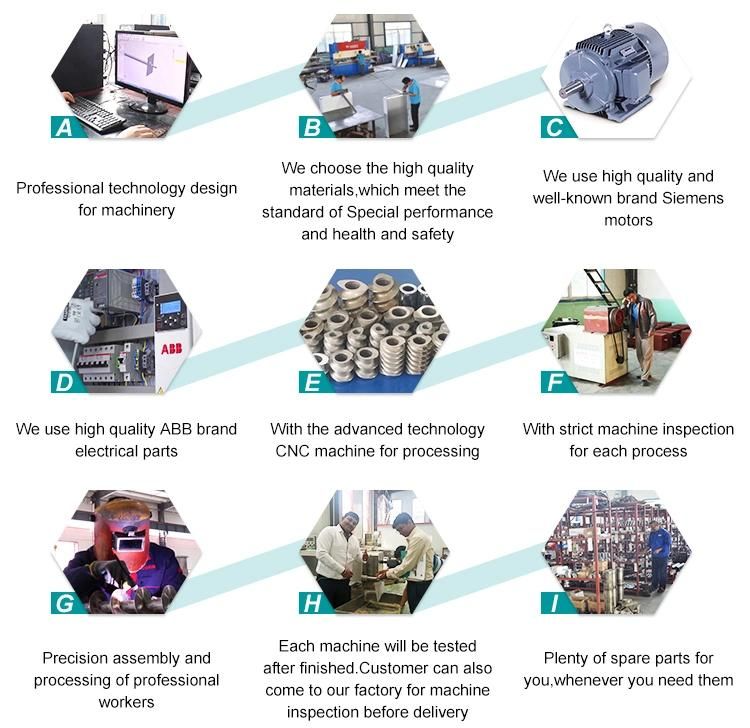

- Motor:Chinese or Siemens or ABB

- Guarantee:12months

- After Sale Service:Engineers Available to Oversea Service.

- Temperature:Visible

- Transport Package:Wooden Case

- Specification:20000 kg

- Trademark:SBN

- Origin:Jinan Shandong

- HS Code:8438800000

- Production Capacity:100 Kg,H. 180 Kg,H. 250-300 Kg,H. 500-600 Kg,H. 1.

=== Description ===

IV. Corn Kurkure Cheetos Processing Line

1. Capacity: 100-150 kg/h, 300 kg/h, 400-450 kg/h.

2. Processing line: Mixer--Screw conveyor--Extruder--Hoister--Roller sifter--Hoister--Continuous feyer--Viberate Shifter--Hoister--Flavouring line--Cooling Conveyor--Packing Machine

V. Accessories and materials

V. Accessories and materials

VI. Customization and other features1. We can provide you with appropriate machine instructions according to your needs.

2. Voltage: three-phase 380V / 415V / 440V, etc., we can customize according to the local voltage of the country where the customer is located.

3. Color etc. can also be customized.

VII. Our services

Pre-sale service

1.Provide customization: 15 years of customization experience can help you customize the machine according to your needs according to output, site area and structure.

2. Project planning and design service.

3. Remote video test machine, and provide mailing service (postage at your own expense).

4. 24-hour online consulting service.

5. Live watch factory service.

After-sales service

1. Provide 1 year complete warranty and life-time maintenance service. Discount on spare parts purchase after one year.

2. 24-hour online guidance and commissioning service.

3. New production techniques and formulas.

4. Provide training services.

VIII. Our factory

Is the largest factory in the industry.

1. Factory standing area: 30000 square meters Workshop standing area: 20000 square meters. Office area: 4 floor with 600 square meters.

2.Full functional department: Research and development department,Technical design team,manufactur team,Inspection team,after sale service team.

IX. Delivery

IX. Delivery

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23