Acrylic Recycling Machine

Ningbo Yinzhou Evershine Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. ZQ-TP10 Transport Package Bulk Specification 2.6m*7.7m Trademark JINZHONGQING Origin China HS Code 8419409090 Production Capacity 12setsProduct Description

ZQ-TP10 model WASTE Acrylic Recycling machine with CE & ISO

1. Feasibility of the WASTE Acrylic Recycling machine

Note: A. This analysis is made with capacity of 10Mt tyres per day per batch.

B. Please modify relative prices according to your actual market conditions.

| NO. | ITEM | DETAILS |

| 1 | DAILY CAPACITY | 10MT |

| 2 | Raw Materials | Waste tyres |

| 3 | Cost of tyres | 10T*700¥/MT=7000¥ |

| 4 | Cost of Catalyst | 10MT*0.3%*5000¥/MT=150¥ |

| 5 | Labor (DAILY) | 4P*150¥/D/P=600¥ |

| 6 | Electricity & Water | 300¥ |

| 7 | FUEL COST | 0.2MT*3000¥/MT=600¥ |

| 8 | Other maybe happen | 200¥ |

| 9 | Total Cost | 8,850.00¥ |

| 10 | Oil Income | 10MT*40%*3000¥/MT=12,000.00¥ |

| 11 | Steel Income | 10MT*12%*1600¥/MT=1,920.00¥ |

| 12 | Carbon Income | 10MT*35%*260¥/MT=910.00¥ |

| 13 | Gross Income | 14,830.00¥ |

| 14 | Daily Net Income | 14830¥−8850¥=5980.00¥ |

| 15 | Monthly Net Income | 5980¥/Day*25D=149,500,000.00¥ |

| 16 | Yearly Net Income | 149,500.00¥/M*11M=1,644,450.00¥ |

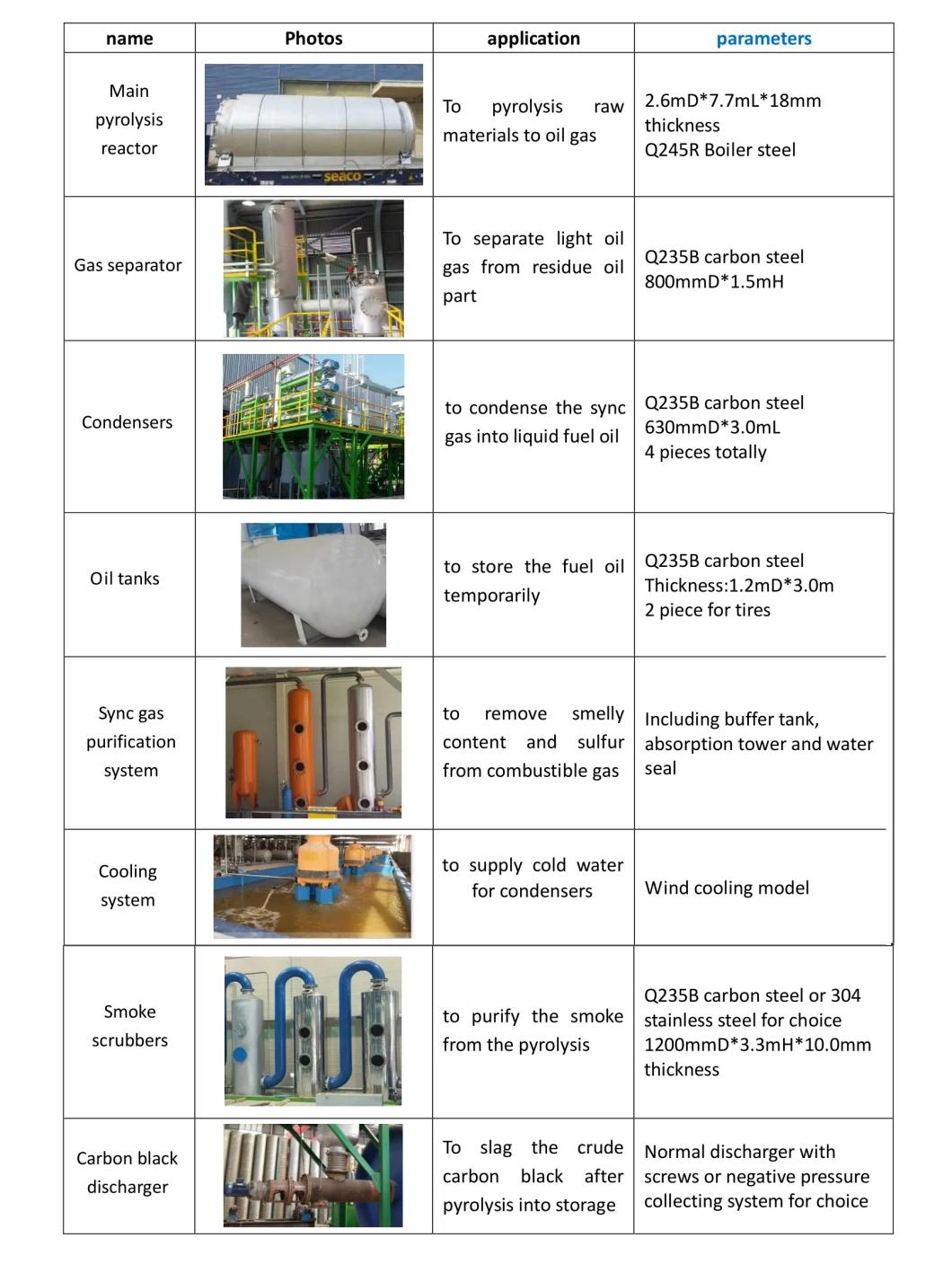

2. Main Parts of tire recycling machine Plant

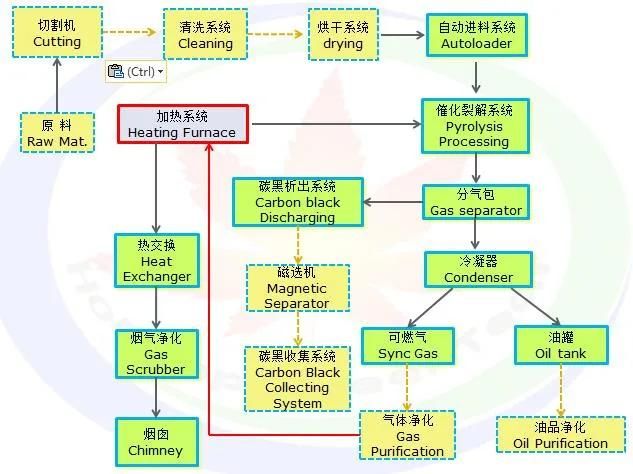

3. Operation Process of the Acrylic Recycling machine:

- General introduction: The cut tires or tire bundles or whole tires (with less capacity) or plastic bundles feed into reactor directly, then close tightly the reactor door, and begin heating.

- When the gas separator temperature rise up to about 100degrees C, the oil gas will generate and flow through the gas separator. The heavier content falls down and back to reactor, the light part go up to the condensers and turned into liquid oil stored in oil tanks.

- The uncondensed sync gas will be purified to remove acid part and the odor, then back to furnace burned as fuel to heat reactor.

- When whole process finished, cooled down the reactor to about 80 degrees C and open the discharger, begin discharging carbon black.

- Sync Gas:The sync gas generated about 3~8% totally according to the oil water content, it is pollution gas, but with huge heating value, cannot be emitted directly. We adopt gas purification and recycling technology, all such gas will be purified first to remove the Sulphur and Chlorine content, then recycled to the burning room burned as fuel to save operation cost as well as prevent gas pollution. If buyer need, also can collected and pressed such gas into tank to generate electricity or sold to market.

- The principle we use is high temperature distillation, we suggest the normal temperature not more than 360ºC, and the pressure in the whole process is not higher than 0.02 MPa. We also use gas purifying system in our new design, after purifying, the emissions is cleaner, which is more environment friendly. In a word, it is safe, energy-saving, environment friendly and easy to operate.

4. the Acrylic pyrolysis end Product, Percentage and usage:

| Name | Percentage | Usage |

| plastic oil | 85%~95%, usually about 40% | Used to make new Ar |

| Carbon black | About 5% | Crude carbon black can be used for construction bricks, or widely used as industrial semi-reinforcing carbon black like N774, N660or color carbon after deep-process |

| Sync gas | 4% | recycled to be used as fuel for operation or storaged as LPG. |

| Inner water | about 1% | purified and then used as water for cooling. |

5. Outstanding Features of our ZQ-TP Acrylic recycling machine

- 5.1: Better security. The biggest safety hazard of the pyrolysis plant lies in the possibility of explosion and fire. And the two security risks are all caused by excessive pressure, so how to deal with it?

Our company adopts the prevention method, that is, we won't allow the pressure to be too high; the other companies adopts the treatment method after the pressure is higher, that is, when the pressure has been too high, the safety valve installed at the rector door would be driven to be exploded due to high pressure to carry out the pressure for emergency relief. The disadvantage of this method is that even if the pressure leaks out of the reactor, the possibility of fire occurs at the same time with the occurrence probability as high as 90% or more. And the fire will in turn affect the main reactor.

The preventive measures adopted by our company are: to ensure the smoothness of the pyrolysis operation and the pipelines at all times, and to prevent plugging and leaking; if there is no blockage, the pressure will not suddenly rise, and there will be no reactor explosion or fire without pressure!

As well as the emergency relief valves equipped in other locations, the water seal anti-tempering safety device, etc. are conventional configurations and will not be described here.

5.2 High oil yield and good oil quality: Other companies often have residual oil tanks or heavy oil tanks, and each batch production will produce 100kg~400KG residual oil or heavy oil. This kind of residue oil is very viscous and very dark in color, cannot be sold directly or sold at very low prices. If you mix this residue oil with good quality fuel oil, it will lower the quality of the oil and lower the price. If you throw away it is kind of waste and will pollute the environment. If it is extracted and put into the pyrolysis reactor again for cracking, it will waste labor and the process is dirty.

The anti-blocking device used by our company rotates counterclockwise during production, and the residual oil and other impurities separated from the gas separation package can be pushed back into the reactor for secondary cracking until all high quality oil extracted. The impurities are partially dried to powdery carbon black. Therefore, in one batch, the oil production rate from our machines is 2% to 5% higher than that from other companies; at the same time, it removes the secondary treatment of residual oil and possible pollution problems.

At the same time, the technology of this invention patent reduces the rate of the phenomenon of carbon black rising due to the rotation of the reactor in the production processby more than 90%, which makes the carbon black content in the oilgreatly reduced, improves the quality of the oil.

5.3: The equipment pipeline cleaning period is greatly extended: the anti-blocking system adopted by our company ensures the cleanliness of the pipeline while restraining the carbon black from entering the pipeline, which makes the cleaning cycle of our equipment doubled compared with other equipment, which saves Human resources, in turn, enable the equipment to continue to operate.

5.4: Our equipment has better sealing performance: the sealing performance lies in two aspects, one is the sealing at the reactor door and the other is the sealing at the air outlet location. In terms of reactor door, our design is more reasonable and elliptical, and the door is reinforced several times. No matter which kind of raw material is fed, this design can balance the convenience of full door opening and reduce the possibility of door deformation. The elliptical design allows the high-quality packing to slowly change direction when the corner seal is made, the packing structure does not change, and the small square or round door is not convenient to feed the materials, and second the packing is suddenly changed, which makes the structure become slack and is prone to air leakage.

Our reactor door is made of anti-deformation material and design, it will not be deformed, drooping or tightly sealed for a long time.

Sealing at the air outlet location, our company adopts an integrated design, that is, the air outlet is welded directly to the reactor body to increase the sealing performance, and the two-way sealing design makes the possibility of air leakage lower. The outlet designed by other companies are mostly a simple straight package, and there is no design for two-way sealing.

5.5: Anti-stick and automatic clearing device: Our equipment adopts heat treatment and filming process on the inner wall of the reactor before the first usage, so that the coating agent can penetrate into the steel of the furnace wall to form a plated film, which can prevent the reactor wall from sticking together, avoid flash explosions. The automatic clearing machine adopts the chain scraper structure, and the clearing is more thorough.

5.6: Equipment quality: first, the materials used is really national standard furnace steel, no non-standard materials.

The second is the welding process: our company adopts automatic welding process, no trachoma, and the welding surface is neat and beautiful.

Third, Built-up in the first class workmanship and superior parts. Every single plant has passed the severe inspection procedures to ensure the best quality to be delivered to each of our customer.

5.7: After-sales service: The equipment is maintained for life. If there is any problem, the confirmation reply will be given within 24 hours after the sale, and the 48-hour personnel will start the on-site service in China or begin the preparation to apply for visa.

5.8: Highly automatic control system, Digital Monitoring and PLC System optional.

6. Our Certificates of CE + ISO 9001 and ISO 14001 certificates:

7. Sales after service of our company:

- Quality warranty period: One year warranty for the reactor ,and lifetime maintenance for complete set of machines. pay the double air tickets, accommodation and food.

- According to the requirement of the buyer, our company sends engineers for installation and commissioning in buyer's site including the training of skills of buyer's workers on operation, maintenance, etc.

- Supply layout according to buyer's workshop and land, civil works information, operation manuals, etc. to the buyer.

- For the damage caused by the users, our company provides the parts and accessories with cost price.

- Our factory supplies the wearing parts with the cost price to clients.

Welcome to us, please contact:15343866766.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23