Glorystar 3000W Fiber Laser Cutting Machine

Xingyuan Plastic Manufacturing Co., Ltd / 2022-06-23

- Application:Agriculture Machinery, Automotive Industry, Advertising Industry, Metal Processing

- Cooling System:Water Cooling

- Technical Class:Continuous Wave Laser

- Applicable Material:Metal

- Structure Type:Large Full-Enclosed & Exchangeable Worktable

- Laser Classification:Fiber Laser

=== Base Info ===

- Model NO.:GS-3015CE,GS-4020CE,GS-6025CE

- Laser Technology:Laser Control Fault Cutting

- Model No:GS-3015ce

- Working Area:3000*1500mm

- Laser Power:4000W

- Laser Type:Fiber Laser Generator

- Transport Package:Package by Plywood

- Specification:CE, SGS, FDA, Bureau, ISO

- Trademark:Glorystar

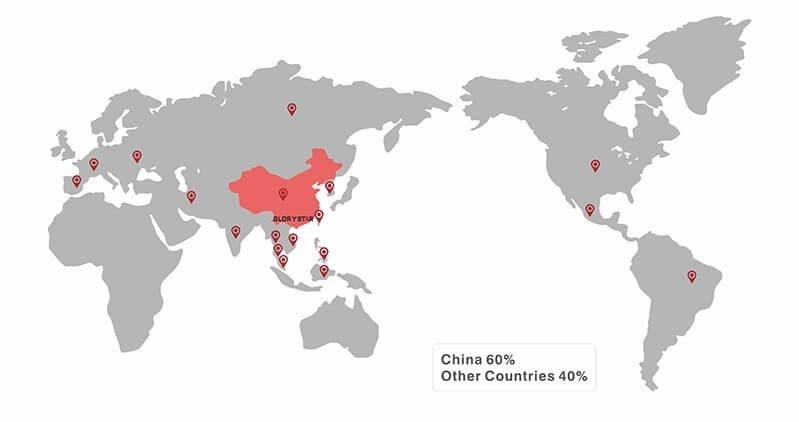

- Origin:Dongguan City, Guangdong Province, China

- HS Code:8456100090

- Production Capacity:8000PCS,Year

=== Description ===

Basic Info.

Model NO. GS-3015CE/GS-4020CE/GS-6025CE Laser Technology Laser Control Fault Cutting Model No GS-3015ce Working Area 3000*1500mm Laser Power 4000W Laser Type Fiber Laser Generator Transport Package Package by Plywood Specification CE, SGS, FDA, Bureau, ISO Trademark Glorystar Origin Dongguan City, Guangdong Province, China HS Code 8456100090 Production Capacity 8000PCS/YearProduct Description

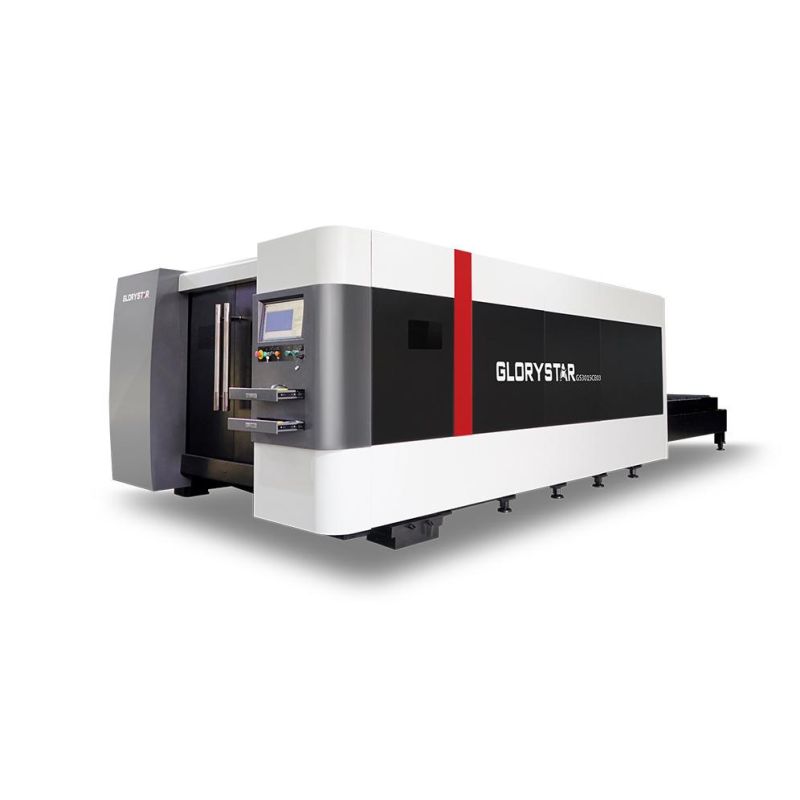

3000W Hot Sale High-Speed Fiber Laser Metal Cutting Machine GS-3015CEThe GS-CE exchangeable table fiber laser cutting machine is a fully enclosed fiber laser cutting machine

>>> Product Introduction

The GS-CE exchangeable table fiber laser cutting machine is a fully enclosed fiber laser cutting machine . The fully enclosed design can not only reduces the damage of the laser radiation to workers, but also effectively prevent metal debris splash from causing damage to operators. The power of GS-CE fiber laser cutting machine can achieve the maximum power of 10000W, and can be used for a variety of precision parts and machine panel cutting, punching, lettering and so on. The products processed by the fiber laser cutting machine have little influence on the cutting seam by heat and generally do not need secondary processing.

>>> Advantages

Using IPG laser source, the electro-optical conversion efficiency is high, which can save power consumption during work and save operating cost.

The design of the dual platform, when one workbench is cutting, the other workbench can simultaneously work on the loading and unloading to improve work efficiency.

The focal length of the cutting head can be self-adjusted following the surface height of the material, even if the surface of the material is not flat, the cutting quality can be guaranteed.

Equipped with a handheld controller, you can manually control the cutting position.

With precision ball screw, rack and pinion, linear guide transmission operation, thus achieving high precision, high efficiency and stability of the machine tool.

The switch of the solenoid valve and the proportional valve is controlled by the system. The input value in the numerical control system can control the size of the proportional valve outlet, without manual adjustment.

High-strength integrated welding fuselage and aerospace-grade aluminum alloy beams are subjected to high-temperature annealing to ensure long-term use without deformation.

| Machine model | GS-3015CE | GS-4015CE | GS-4020CE | GS-6020CE | GS-6025CE |

| Laser power | 500W to 20000W (optional) | 500W to 20000W | 500W to 20000W | 500W to 20000W | 500W to 20000W (optional) |

| Processing format (L/W) | 3000*1500mm | 4000*1500mm | 4000*2000mm | 6000mmx2000mm | 6000mmx2500mm |

| Max. X-axis stroke | 1530mm | 1530 | 2030 | 2030 | 2530 |

| Max. Y-axis stroke | 3050mm | 4050 | 4050 | 6050 | 6050 |

| Undefined Max. Z-axis stroke | 290mm | 290mm | 290mm | 290mm | 290mm |

| undefinedX/Y axis geometric positioning accuracy | ≤0.05mm (full range) | ≤0.05mm (full range) | ≤0.05mm (full range) | ≤0.05mm (full range) | ≤0.05mm (full range) |

| X/Y axis repeated positioning accuracy | ≤0.03mm | ≤0.03mm | ≤0.03mm | ≤0.03mm | ≤0.03mm |

| Machine size | 8800*3000*2000mm | 10000*3500*2000mm | 11000*3900*2000mm | 15100*3500*2000mm | 15100*4000*2000mm |

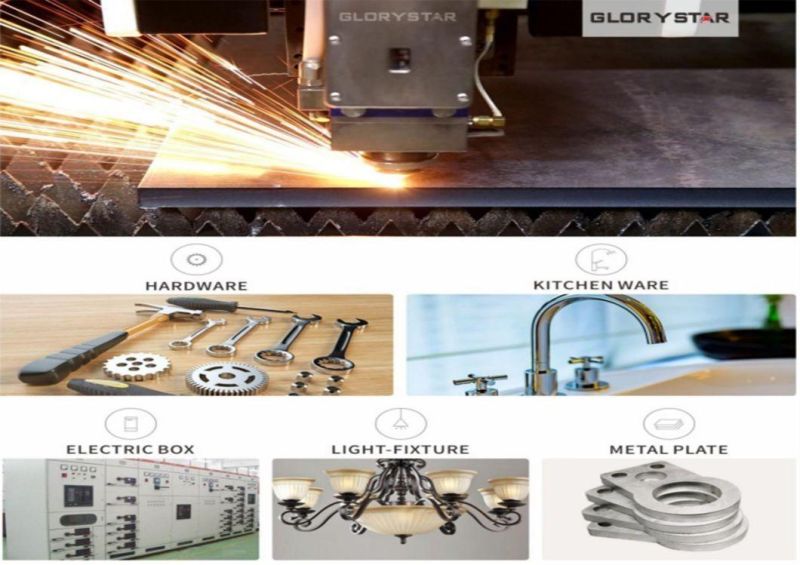

1. Application Industries: Widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.

2. Application Materials: Suitable for metal cutting with Stainless Steel Sheet, Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Iron Plate, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Metal Sheet,Metal Plate, Tubes and Pipes, etc.

>>> Sample

Brass 5,6,8,10mm cutting by 3kw

3kw cutting samples

>>> Quality Control and R&D

>>> After-sale Service

Installation and debugging

Technicians can be sent to the factory for training (free of service fee for the first time). Customers only need to provide accommodation for engineers.

Training

Free of charge for training within warranty. But customers need to take charge of the cost for accommodation, air tickets, visa fee.

24/7 online service

All our laser equipment is provided with 12 months warranty. Glorystar Laser offers free maintenance or replacement service if something is wrong with the equipment under warranty. If it is out of warranty,Glorystar Laser will send engineers to your factory as soon as possible and only charge the cost of parts.

Accessories supply

IPG laser source is 2 years. Other parts is one year except for optical and consumable parts. Prolong serve is always available for option. Free of charge for fixing and changing parts within warranty. Only changing parts , the freight should be charged by customers.

Remote diagnosis

Glorystar Laser can check the running status of the customer's laser cutter through our remote maintenance system. Our technicians can perform troubleshooting via remote access instead of on-site diagnosis and maintenance, saving you a lot of time.

Additionally, Glorystar Laser will establish a special user profile for all customers who have purchased equipment from us to record your usage, maintenance records and other information. This will help us to learn about customer information more quickly and thus provide necessary upgrades according to customer feedback

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23