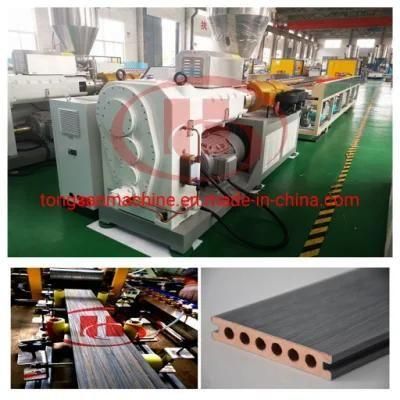

Wood Plastic Composite WPC Machine WPC Engineered Flooring Decking Making Machine

Ningbo Easyget Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJMS-51/105, 65/132, 80/156 Certification CE, ISO9001:2008 Customized Customized Raw Material Recycled PP PE,Wood,Chemical Additives(WPC Granule Final Product WPC Floor,WPC Decking,WPC Profiles Machine Type Wood Plastic Composite WPC Machine Production Machine WPC Decking Making Machine Transport Package Bubble Wrap Specification Customized Trademark TONGSAN Origin China HS Code 847790 Production Capacity 10 Sets Per MonthProduct Description

wpc engineered flooring decking making machineWPC machine/Turn-key project wood plastic composite WPC machine

Our Qingdao Tongsan Plastic Machinery is specialized for making kinds of PP/PE/PVC WPC wood plastic composite machines for more than 24 years. We developed advaced technology.To offer customer high quality machine and good after-sale service.

Our main products:

(1)PP/PE WPC wood plastic composite WPC profile making production machine for making outdoor WPC decking,fence, post, pallet, flooring, chair ,house wal panel etc.

(2)PVC/UPVC WPC wood plastic composite WPC profile making production machine for making window and door profile making machine, wall and ceiling panel etc.

(3)PVC/UPVC WPC wood plastic composite WPC door panel making production machine for making door panel and door board.

(4)PVC/UPVC WPC wood plastic composite WPC foam board making production machine for making celuka foam board.

Workshop

Office building

Office building

Material: Wood powder ( waste wood brick,wood sawdust,rice husk,plant straw,etc) Plastic( Recycled PP/PE flake/granule,recycled PVC powder,orginal PVC powder)

Production proecss:

PP PE Wood Plastic Composite : milling→mixing→granulating→extruding→final product surface treatment

PVC Wood Plastic Composite : milling→mixing→extruding→final product surface treatment

The features of WPC wood plastic composite making machine

1)This technology is suitable to produce WPC products at high value with variety of plastic and nature fiber,and the material is 90% of waste plastic and waste natural fiber.

2)With scientific and reasonable technology,the machine has high efficiency and runs stably

3)The parallel twin screw extruder is used to mix the wood and plastic,and get good homogeneous melt.

4)This is one step WPC extrusion technology,which saves energy

5)This production line can produce wpc products of different specifications only to change mold.

6)Imported PLC automatic control.

The final product application: floor,decking,pallet,outdoor landscape architecture,fence,post,wall panel,door and window profile,etc.

By changing the moulds,the wood plastic compoite machine can produce vairous of profiles.

The mould can be customized by client's requirement

Conical double screw extruder

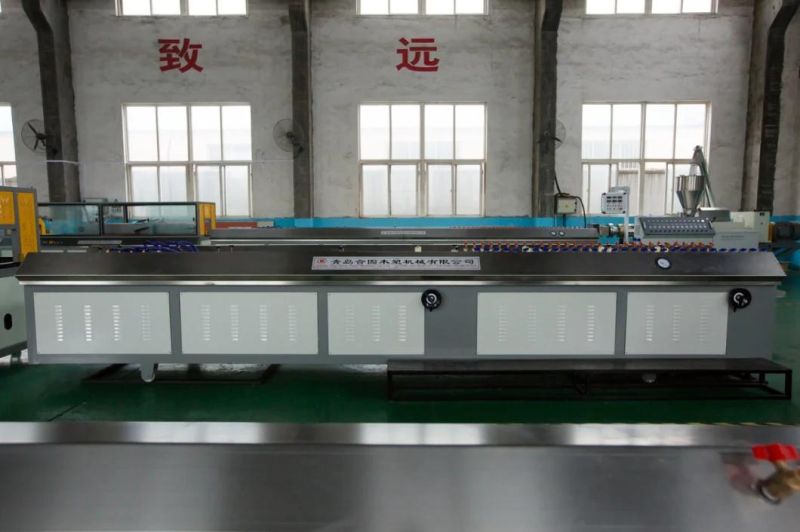

Calibration platform

Haul-off device

Cutter

By changing the molds,this WPC machine can produce WPC decking,WPC wall cladding,WPC outdoor board,etc.

The WPC profile application

The WPC profile application

If you are interested in our machine,please let me know at any time.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23