1000W Fiber Laser Cutting Machine for Carbon Steel

Yuhuan Green Island Plastic Packaging Factory / 2022-06-23

- Application:Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Shoemaking Industry, Woodwork Industry, Advertising Industry

- Cooling System:Water Cooling

- Technical Class:Pulse Laser

- Applicable Material:Metal

- Structure Type:Gantry Type

- Laser Classification:Semiconductor Laser

=== Base Info ===

- Model NO.:014

- Laser Technology:Laser Fusion Cutting

- Model No.:Dplc3015-1000I

- Type for Cutting Machine:Laser Cutting Machine

- Automation:Automatic

- Type:Laser Cutting Machine

- Laser Wavelength:1070nm

- Application of:Machinery & Hardware

- Certification:SGS, Ce, ISO 9001:2000

- Condition:New

- Medium of Laser:Semiconductor Pump Continuous Ytterbium Doped Fibe

- Export Markets:Global

- Transport Package:Wooden Box

- Specification:CE, SGS

- Trademark:DP

- Origin:Shenzhen, China

- HS Code:84561000

- Production Capacity:650,Year

=== Description ===

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications, but is also starting to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. A typical commercial laser for cutting materials would involve a motion control system to follow a CNC of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

DP FIBER LASER CUTTING ADVANTAGES:

1, Cost saving on power consumption/ only 20-30% of co2 laser cutting machine under same power.

2, Flexibility and precision cutting of simple or complex parts

3, Adopts imported world brand fiber laser/Life time over 100,000hrs

4, Imported servo motor and gearing system ensure precision cutting

5, High quality cut with no extra finishing required

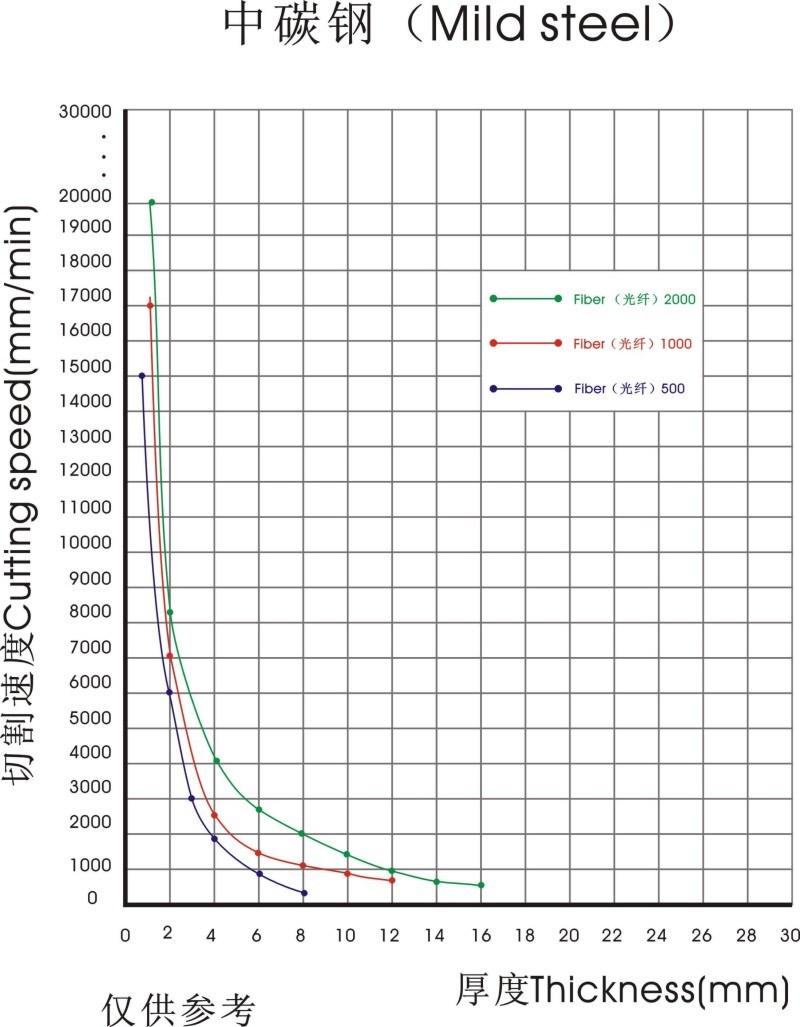

6, Higher cutting speed and efficient, speed of cutting plate over 10 meters per minute

7, Non contact cut which means no marks or contamination of the material

8, Ability to cut virtually any sheet metal

SPECIFICATIONS:

Model

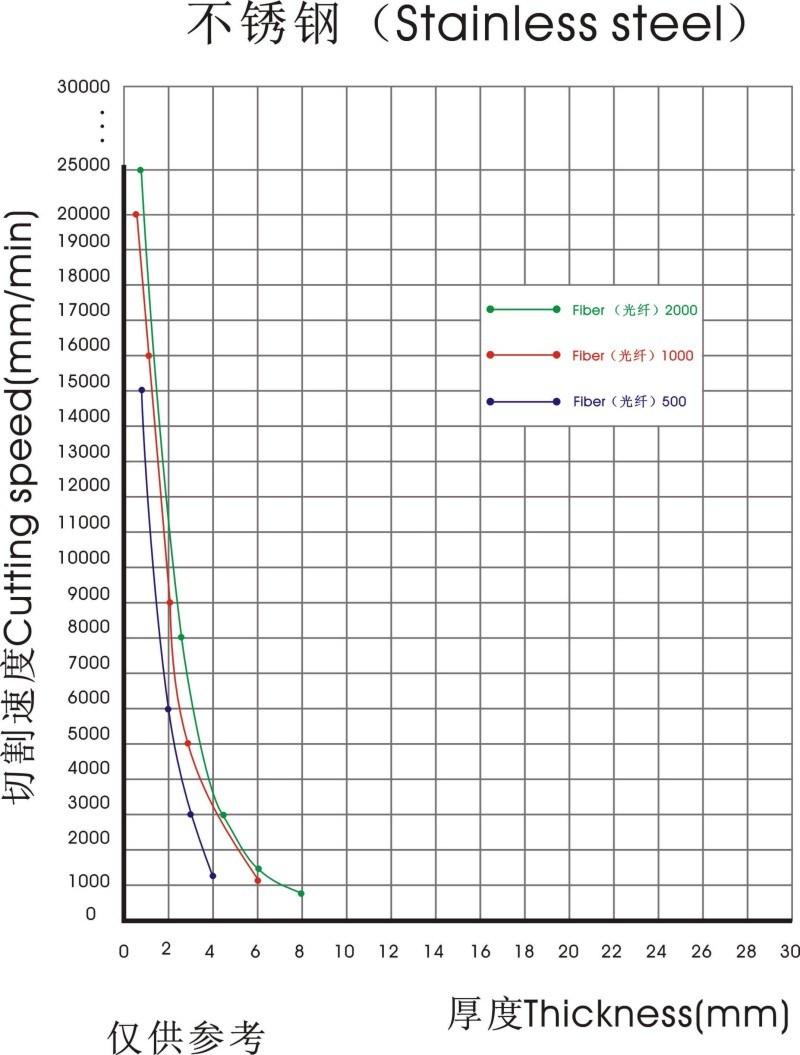

Machine Cutting Performance

APPLICABLE MATERIALS:

Stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet and other metal pipes and tubes.

APPLICABLE INDUSTRY:

It is widely applied in industrial pipeline processing, explosion-proof equipment, military industry, chemical industry, oil exploration, lamps and lanterns, metal processing, ironware, building, etc.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23