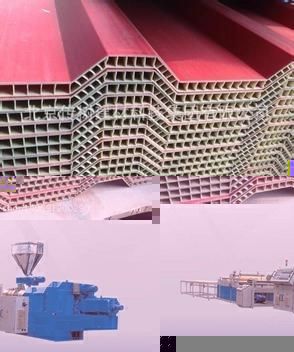

PVC Hollow Roofing Tile Production Line

HEBEI ZHENPENG INTERNATIONAL TRADING CO., LTD. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Suitable Material PVC Product Width(mm) 900mm Product Thickness(mm) 0.5-3 Max Extrusion Output (Kg/H) 220-400Product Description

Practical Application:

1.Using ASA co-extrusion appearance,to make finished products more colorful,ensure its quality

because of weather-resistance and long-life,whose inner is UPVC material.

2.Compared with traditional ones:good temperature insulation,heating insulation,noise insulation,

anti-corrosion,anti-rust,a good physical character,long-lasting structure and convenient and fast

installation,which is suitable for factory,school,playground,warehouse,house,agricultural

greenhouse,commercial buildings,which is very environmental materials.

Technical Parameters

Model | Extruder Name | Production Speed(m/min) | Max Output (kg/h) | Max Product Width(mm) | Power(kw) |

| SWBL-1Z | Hollow Wave Titles Extruder | 0.5-3 | 220-380 | 900 |

1. PVC Middle Hollow Wave Tile Extrusion Production Line

1), Middle-hollow wave tile character and application

The extrusion line is made of extruder, extrusion mold, shaping system, haul-off machine, cutter, discharging table,etc. Moreover, extrusion mold adopts co-extrusion multiple technology and multi cavity flow design. Froming is adopting vacuum -shaped and special designed cold flow,which has good cooling effect. Compared with traditional tiles, PVC middle-hollow wave tiles with co-extrusion ASA has colorful appearance, good sound-proof effect and weather-resistance like corrosion-resistance, acid-resistance and anti-UV, etc. Easy and simple installation is best choice for agricultural shed, factory (chemicals, medicines), sports ground, school, warehouse, business buildings etc.

2. PVC Middle Hollow Wave Tile Extrusion Production Line Configuration

| Serial | Equipment Name | QTY |

| 1 | Spiral loader machine | 1set |

| 2 | SWZBL-1(80/156) conical twin-screw extruder | 1set |

| 3 | Vacuum loader machine | 1set |

| 4 | Drying hopper | 1set |

| 5 | SWD50/30single screw extruder | 1set |

| 6 | Extrusion mold | 1set |

| 7 | Distributor | 1set |

| 8 | Forming mold | 1set |

| 9 | Forming table | 1set |

| 10 | Haul-off machine | 1set |

| 11 | Cutter | 1set |

| 12 | Stacker | 1set |

1. Additional Equipment

| Serial | Equipment Name | QTY |

| 1 | Ridge tile | 1set |

| 2 | Press machine and baking box | 1set |

| 3 | Spiral loader | 1set |

| 4 | Mixing machine | 1set |

| 5 | Crusher machine | 1set |

| 6 | Milling machine | 1set |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23