Turnkey Project Orange Apple Juice Processing Plant

Jiangyin Yiran International Trading Co., Ltd. / 2022-07-05

- Type:Fruit Juice Processing Line

- Voltage:380V

- Power:Different Capacity Different Power

- Customized:Customized

- Color:Customized

- Transport Package:Wooden Case or Film

=== Base Info ===

- Model NO.:GY-6

- Specification:small or big capacity

- Trademark:Genyond

- Origin:China

- HS Code:8438800

- Production Capacity:10set ,Month

=== Description ===

Basic Info.

Model NO. GY-6 Specification small or big capacity Trademark Genyond Origin China HS Code 8438800 Production Capacity 10set /MonthProduct Description

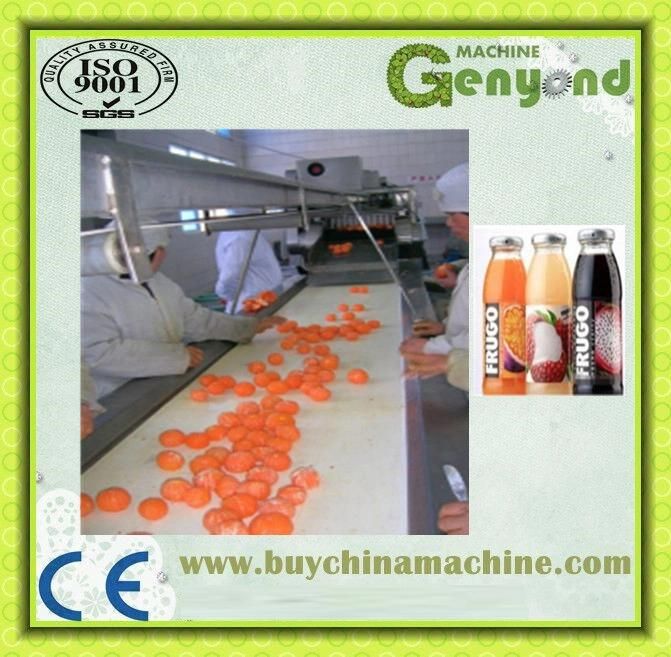

Compound fruit juice prcessing line /plant/production line, orange apple fruit juice processing line

This production line input capacity 100kg ,200kg ,500kg, 1000kg,2000kg ,3000kg ,can customized .

Basic Parameter

1 | Material | Fresh fruit |

2 | Final product | Glass bottle ,PET bottle ,Compound bag of packing fruit juice or fruit paste/jam |

3 | Process capacity | 100--3000kg/h concentration fruit juice fruit paste/jam |

4 | Period of investment return | The line less investment, compared with large line can be in a relatively short time to recover the cost |

5 | Effective input | 100-3000kg fruit juice fruit paste/jam /h (5% waste material ,etg: stone ,skin output) |

6 | Effective output | According to different fruit different |

7 | Composition of fruit juice | Pure juice, turbid juice, pulp fruit juices and juice with sugar, pure jam, flavor jam, etc |

8 | Sterilization ways | Pasteurization, high temperature sterilization, super high temperature sterilization ( according to inquired ) |

9 | Final packing | 200ml-500ml Glass bottle ,PET bottle ,Compound bag |

10 | Output capacity | 50kg -3000kg/h (according to fruit different .) |

Production line features:

1. Multi-purpose, can produce different kinds of fruit juice and jam.

2. System integrity: to clear juice, turbid juice, juice concentrate and jam, and other products, from cleaning, picking up the fruit, juice is broken, preheat enzyme, enzymolysis, filtration, allocate, degassing, homogeneous, sterilization, filling, complete until the final product packaging production line.

3. The independence of the key equipment: oven to the process of research, for some devices, can form a complete set with the system, can also be used independently, without ancillary facilities, and save energy.

4. Low yield could design.

5. Reduce the production cost, reduce downtime and reduce maintenance, complete production line monitoring, automatic cleaning system.

Processing Chart :

Washing -----peeling and remove kernel------juicing ----filtering -----concentrating -------mixing-----sterilizing -----filling

Supporting Facility

Water consumption:1.5T/H

Circulating cooling water :50T

Power consumption: 55 kw

Steam content: 0.70 tons/hour, 0.4 Mpa

Artificial: about 10 people/class

Area: not less than 850 m2.

Main machine technology description

Fresh fruit pretreatment

All kinds of fruits peel and pitting machine

Crush and juice machine

Concentration

Blending Homogenizing

Sterilization

Filling Section

CIP Cleaning system

Water treatment (for choice )

(if you need packing machine pls tell us which kind packing use?how many valom per packing ?)

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23