15 kg/h stainless steel peanut butter making machine

HANGZHOU PROSPERITY IMP. & EXP. CO., LTD. / 2022-07-05

- After-sales Service:online

- Warranty:1 year

- Type:BUTTER MAKING MACHINE

- Application:All, Beans, Wheat

- Voltage:380V

- Appearance:Vertical

=== Base Info ===

- Model NO.:JTM-50

- Press Materials:COCOA NUT, SESAME, PEANUT etc.

- Press Series:Second

- Condition:New

- Customized:Customized

- Power:1.1 kw

- Capacity:10-15 KG,H

- Transport Package:Wooden Cased by Sea

- Specification:530*260*580mm

- Trademark:VIC

- Origin:Henan

- Production Capacity:1000 Set,Month

=== Description ===

Basic Info.

Model NO. JTM-50 Press Materials COCOA NUT, SESAME, PEANUT etc. Press Series Second Condition New Customized Customized Power 1.1 kw Capacity 10-15 KG/H Transport Package Wooden Cased by Sea Specification 530*260*580mm Trademark VIC Origin Henan Production Capacity 1000 Set/MonthProduct Description

Main application:

This JTM series colloidal mill (butter mill) machine can be applied to mill food,

pharmacy, chemical and other industries, it can crush, emulsify, homogeneity and mix, the main technology is up to international standard.

Scope of Application:

Food processing industry: juice, jam, beans, peanuts, cream, beverage, malted milk, egg yolk, ice-cream, etc.

Chemical industry concerned with products for daily use: grease,water quality,powder cream high-level cosmetics; shoe polish, tooth paste, soap, cleaning detergent, bath extract.

Chemical industry: lubricating grease, paints, coloring agents, emulsified asphalt, cementing compound, etc.

Other industries: plastic industry, pharmaceutical industry, textile industry, construction industry and coinage.

Advantage:

1. Main parts adopt high quality stainless steel, with corrosion resisting and no poison.

2. Main parts stator, rotor adopt specific processing and heating processing technology, with long life and high precision.

3. Stator, rotor and choose different materials, matched with grinding and cutting etc different sturcture and teeth type for choice, the processing gap can be adjusted and with dial, easy to contorl and ensure the processing quality.

4. Matched with cooling system to ensure the processing materials' stucture.

5. Main shaft and motor separate design and the user can choose different rpm according to demand.

Main data:

| Model | JTM-50 | JTM-80 | JTM-110 | JTM-130 | JTM-180 | JTM-240 | JTM-300 |

| Processing fineness(micron) | 50-100 | 50-100 | 100-200 | 100-200 | 100-200 | 100-200 | 60-200 |

| Hopper volume | 3L | 8L | 8L | 10L | 10L | 20L | 20L |

| Diameter of the lower hopper | 40mm | 50mm | 50mm | 90mm | 90mm | 120mm | 120mm |

| Capacity(kg/h) | 10-15 | 70 | 200 | 400-600 | 800-1000 | 1500-2000 | 3000-4000 |

| Power(kw) | 1.1 | 4 | 7.5 | 15 | 18.5 | 45 | 75 |

| Weight(kg) | 50 | 150 | 175 | 285 | 340 | 1300 | 1600 |

| Size(mm) | 530*260*580 | 640*410*900 | 740*430*980 | 830*440*1100 | 830*490*1100 | 1320*600*1280 | 1500*800*1120 |

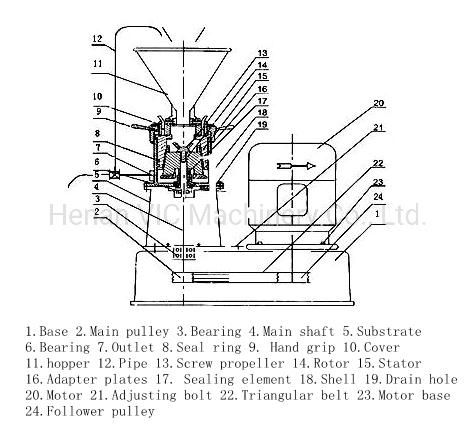

Structure principle drawing:

More photos and details:

Factory corner

Final product(adjustable)

Package

Package

Our Factory

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23