Taiwan Quality Smart Film Blowing Machine

Huzhou Gu's Imp. & Exp. Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. Tp45 Machine Weight 1800kg Certification CE, ISO9001:2008 Screw Diameter (mm) 45 Film Width(mm) 100-500 Film Thickness(mm) 0.006-0.10 Max. Extrusion Output (Kg/H) 50 Die Size(mm) 60/100 High Speed Type Main Motor Siemens Brand Inverter LG Brand Temperature Controller Omron Brand Screen Changer Yes Air Ring Double Vent Air Ring Transport Package Wooden Plate Specification 500mm Trademark RuiGao Origin Ruian Zhejiang China HS Code 847730900 Production Capacity 20 Sets/MonthProduct Description

Taiwan Quality Smart Film Blowing Machine

Its extruder, cylinder and screw rods are made of quality alloy steel that have been notarized and processed

in a precision way. Hence it is hard, durable in corrosion resistance. The specially-designed screw is quality in plasticizing, which helps increase the production capacity. It is applied to blowing the plastic films like

low density polygene (LDPE), high density polygene(HDPE) and linear low density polygene (LLDPE).

It is widely applied to producing the packing bags for foodstuff, clothing, rubbish bag and vest ones.

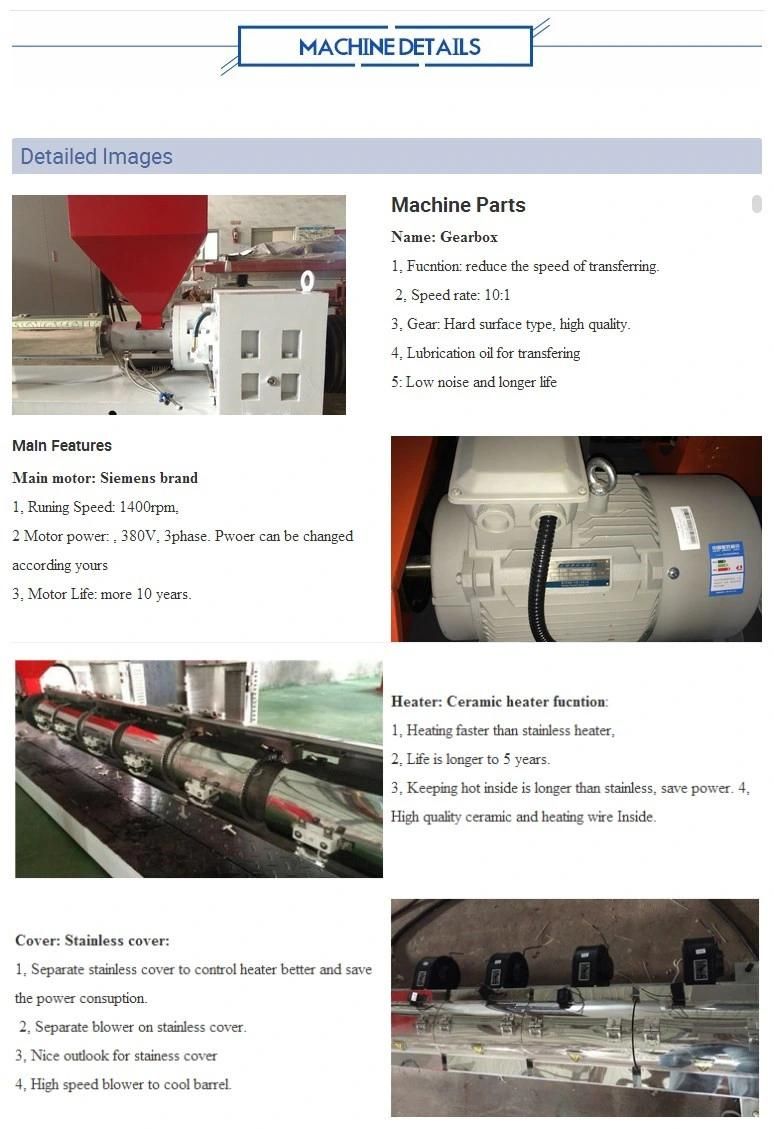

Machine Advantages

1, We use stronger steel plate for machine body, which make machine more stable

2, Screw and barrel is nitrigened by 72 hours. 38 chromium materials, it is very hard. Copied from Taiwan

3, Hard surface gearbox, the life can be more 5 years.

4, Motor with CE standard, more 10 years life, Siemens Brand.

5, Electric parts is CHINT, best supplier in China.

6, Easy to operate and one worker can run 3 sets

7, Temperautre Controller: Omron Brand

8, Inverter: LG Brand

9, Ceramic Heater: Heating faster and Keep warm longer

Machine Parameters

Model | TP45 |

| Diameter of screw | Φ45 |

| Max width of Film | 100-500mm |

| Single-face Thickness of film | 0.008-0.10mm |

| Output | 50kg |

| L/D | 30:1 |

| Power of main motor | 11kw |

| Power of Traction main motor | 1.5kw |

| Total Power | 20kw |

| Outline diameter | 2300 x 2000 x 2300mm |

| weight | 1800kg |

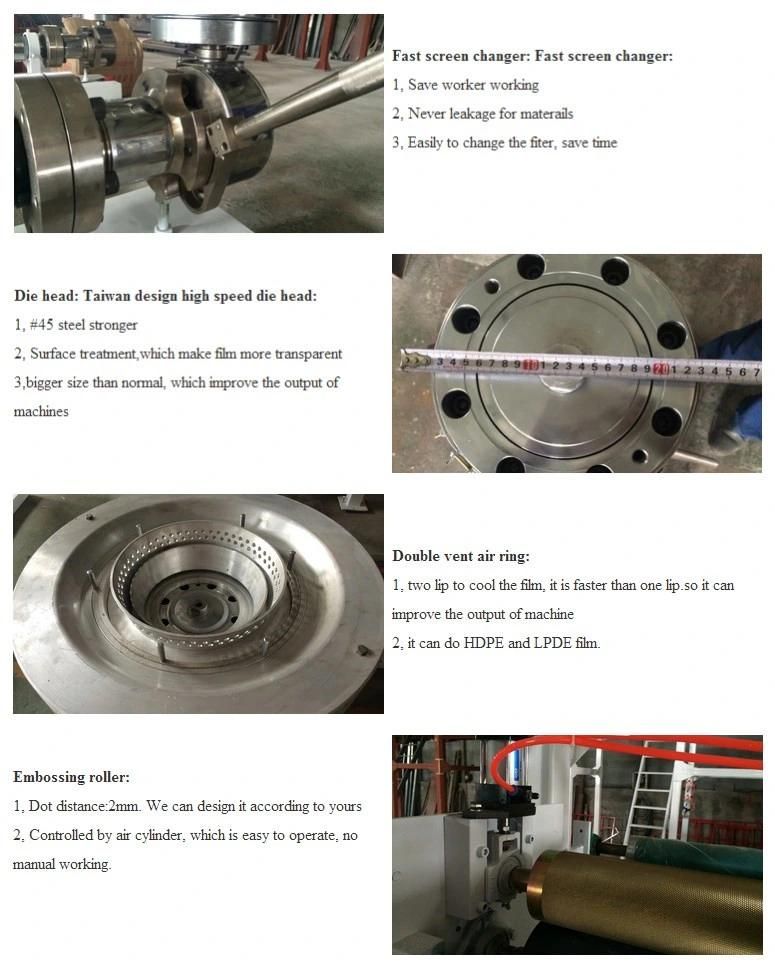

Machine Details

1,Q: Your factory is trading company or factory?

A: We are factory. We have more 2100 square meter workshop and 23 workers containing the 2 installment engineer and 1 electric engineer.

We are Factory, so we have cost advantage than others

2, Q: How do your company control the machine quality?

A: First we control the raw materials quality.

Second, we control the quality of machine when we are processing.

Third, Our installment engineer will test machine.

3, Q: How about payment term, payment safety and delivery time?

A: We accept 30% deposit, balance before shipment. And Irrevocable L/C at sight.

Delivery time is 20 to 30 days. It is according to order quantity.

4,Q: What is your company after sale service?

A: Our installment engineers are available. Normally it will take about 7 to 10 days for all.

Our guarantee is one year. If there is any spare parts is broken, we can send them freely to you.

You are welcome to contact with us, we will provide excellent quotation and high quality machine

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23