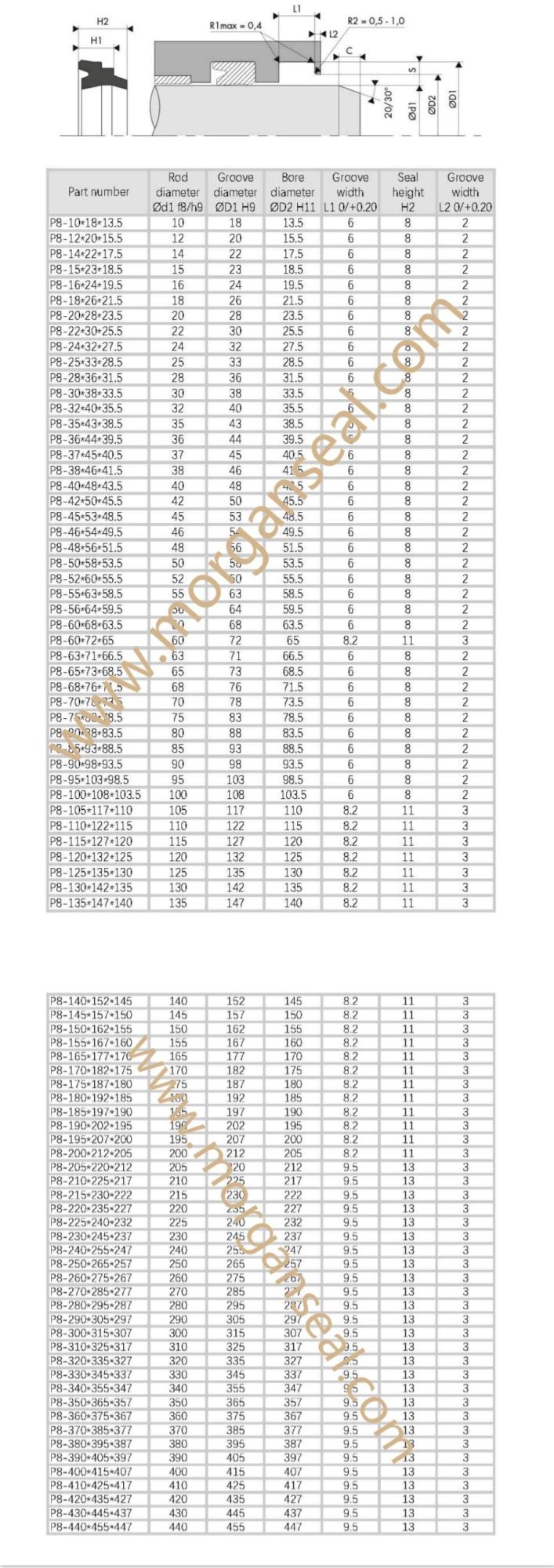

Da17/P8 Profile Hydraulic Cylinder Stepped Double Acting Dust Wiper Seal

Shenzhen Jasun Packaging Co., Ltd. / 2022-06-27

- Certification:ISO9001

- Pressure:Medium Pressure

- Work Temperature:Normal Temperature

- Feature:Wear-Resistant, Tear-Resistant

- Function:Dust Proof, Shaft Seal

- Cross-Sectional Shape:Square

=== Base Info ===

- Model NO.:DA17,P8

- Material:PU,NBR,FKM

- Delivery Date:30days

- OEM/ODM:Yes

- Transport Package:Plastic Bag,Box, Then Carton

- Specification:Custom

- Trademark:Morgan

- Origin:China

- HS Code:3926909090

- Production Capacity:1000000PCS,Month

=== Description ===

Fire-resistant liquids

Biocompatible fluids

Water

Others (contact our experts)

Applications

AgricultureMobile machinery

Material handling - Lifting

Hydraulic cylinders

Industrial vehicles

Presses

Injection moulding machines

Advantages

Low friction

Wear-resistant

Easy assembly by deformation

Good wiping effect, both internally and externally

Very good sealing effect against residual film of oil on the extending rod

Materials

NBR 90 Shore AFKM 90 Shore A

NBR

Nitrile rubber (NBR) is the general term for acrylonitrile-butadiene copolymer. The ACN content can vary between 18% and 50%. While the acrylonitrile content is important, the resistance to oil and fuel is more so. Conversely, the elasticity and compression set are not as good. The NBR has good mechanical properties and good wear resistance. However, its resistance to atmospheric agents and the ozone is relatively low.Mineral oils and greases

Fire-resistant fluids (HFA, HFB and HFC)

Diluted acids, low-temperature alkaline and saline solutions

Water (up to +100°C max)

Aromatic hydrocarbons (benzene)

Chlorinated hydrocarbons (trichlorethylene)

Polar solvents (ketone, acetone, acetic acid, ethylene-ester)

Strong acids

Glycol-based brake fluids

Atmospheric and ozone agents

Fire-resistant liquids (HFD)

Silicone oils and greases

Mineral and vegetable oils and greases

Aliphatic hydrocarbons (propane, butane, petroleum)

Aromatic hydrocarbons (benzene, toluene)

Chlorinated hydrocarbons (trichlorethylene)

Fuel (including high alcohol content)

Atmospheric and ozone agents

Ammonia gas

Organic acids with a low molecular weight (formic and acetic acids)

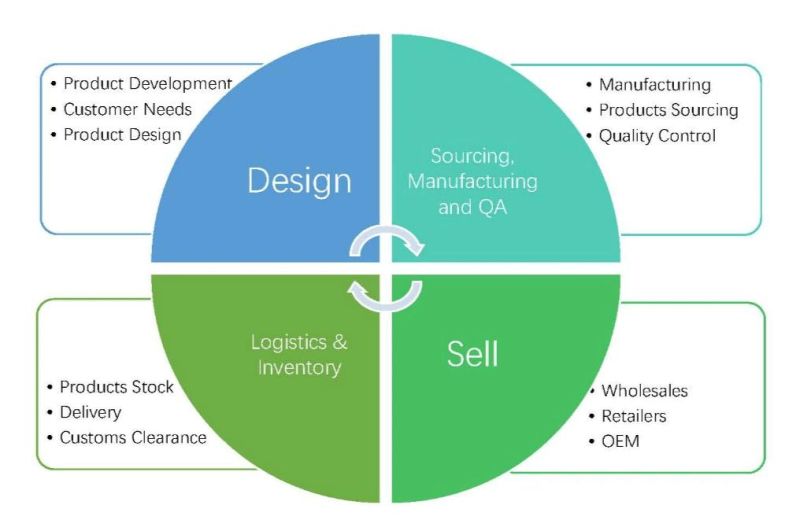

About MorganEstablished by Guangzhou Mechanical Engineering Research Institute Co., Ltd. (51% share, hereinafter to be referred as GMERI) and Morgan Construction Co., Worcester, MA, U. S. A. (49%, hereinafter to be referred as Morgan, Worcester) in 2006, Guangzhou Morgan seals Company Ltd. Is a professional manufacturer for sealing products. Combined the rich seals research and production experience of GMERI with the advanced technology and administration of Morgan, Worcester, the joint venture is renowned for its modern production lines, persisting research & development, strict quality control, quality sales and after-sales service. Now she has gained a good name from her customer all over the world, such as Siemens Primetals, Baosteel, SMS siemag and so on.

Morgan Seals Research and Development ability is based on her parent firm who has won awards as scientific research achievements for more than 1000 projects and over 200 of them won scientific and technological progress prizes of municipal, provincial, ministerial and national levels. At the same time, it also has one National Certified Laboratory, one National Engineering Research Centers and three Industry Level Inspection Centers.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23