Extrusion Blow Molding Machine for PP PE HDPE PVC Bottles

CNBM MATERIAL CO., LTD. / 2022-07-04

=== Base Info ===

=== Description ===

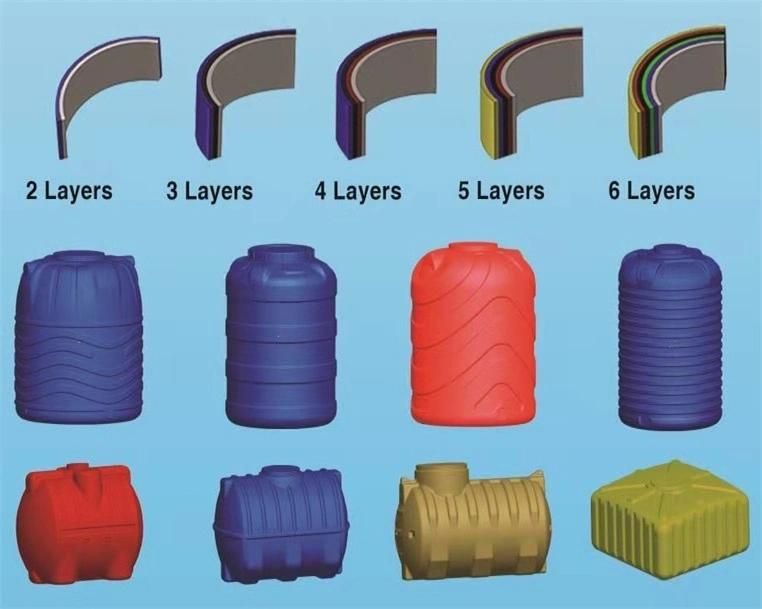

Accumulating type

product display

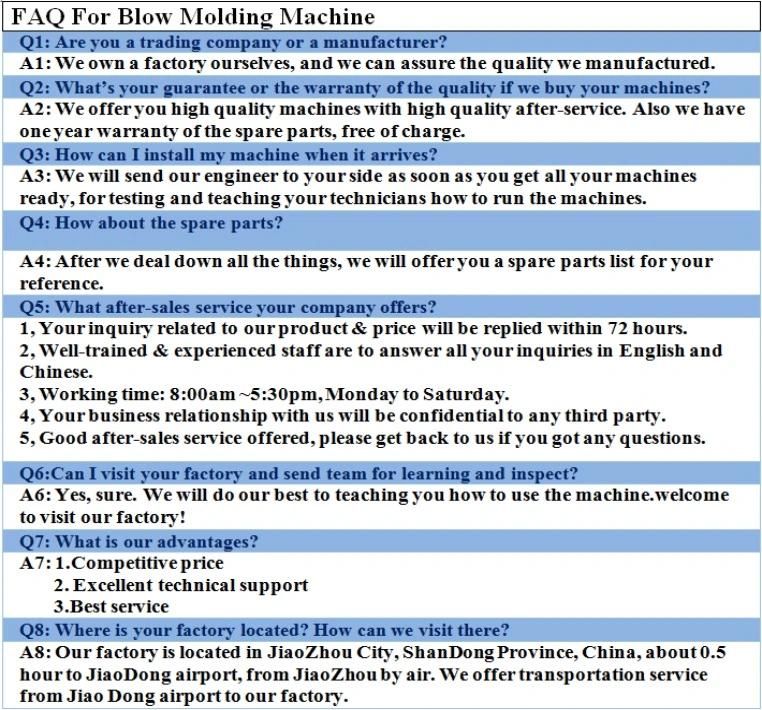

Our service

Our service1.Quality warranty period: One year warranty for the main reactor of pyrolysis machines and lifetime maintenance for complete set of machines.

2.Our company sends engineers for installation and commissioning in buyer's site including the training of skills of buyer's workers on operation, maintenance, etc.

3. Supply layout according to buyer's workshop and land, civil works information, operation manuals, etc. to the buyer.

4. For the damage caused by the users, our company provides the parts and accessories with cost price.

5. Our factory supplies the wearing parts with the cost price to clients.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23