Solid-Wall Pipe Extrusion Machine Twin Pipe Extrusion Machine Line

Fujian Quanzhou Huazuan Diamond Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Condition New Transport Package Plastic Film Package and Loaded Into The Container Specification 28m*5m*5m Trademark Acemien Origin Jiangsu Province HS Code 84772090 Production Capacity 1000 Sets/YearProduct Description

Solid-wall Pipe Extrusion Machine twin pipe extrusion machine lineSolid-wall Pipe Extrusion Machine twin pipe extrusion machine line is designed and manufacturer by our factory Jaingsu Acemine machinery Co.,Ltd. The Solid-wall Pipe Extrusion Machine twin pipe extrusion machine line can produce the Solid-wall Pipe Extrusion Machine twin pipe extrusion machine line. The feares of this PE PP PVC Dual Pipe Production extruder is that thee are two lines for making the plastic pipe. So the producing capacity is big.

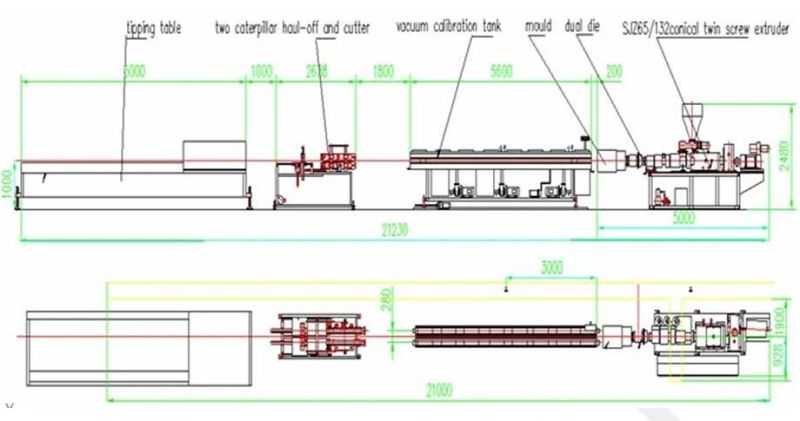

The Solid-wall Pipe Extrusion Machine twin pipe extrusion machine line including below parts:

1 Spring feeder

2 SJZ65/132 twin-screw extruder

3 Mould for drain pipe

4 Vacuum Calibration tank

5 Haul-off and cutter

6 Stacker

Raw material & Final product, and Pipe species and size list: is as below:

Raw material & formulation PVC resin powder & CaCo3, Lubricant; Stabilizers; Pigments; Antioxidants

Description final product PVC pipe , Pipe Diameter: Ф20-40mm

Output capacity Max:250kg/h , Max haul-off speed:12m/min

The working process of the PE PP PVC Dual Pipe Production extruder is as below:

This is the SJZ65/132 conical twin-screw extruder of Solid-wall Pipe Extrusion Machine twin pipe extrusion machine line:

Extrusion capacity 200-250kg/h

Screw Diameter conical 65/ 132 mm

Material of screw: 38CrMoAlA

Surface treatment: Alloy and Nitriding processing, thickness: 0.4 ~ 0,7mm, Polishing

Rotating speed (counter rotating): 1-36.9RPM

Barrel Diameter conical 65/132

Inner processing: Alloy and Nitrided with thickness: 0.4 ~ 0.7mm

Heating zones: 4

Heating mode: Cast Aluminum heater covered with stainless steel

Heating power: 20kw

Cooling mode: Blower 0.37Kw×3sets

Driving motor Motor power: 37Kw AC (SIEMENS)

Dosing feeding system Motor:1.1Kw Double screw forced feeding

Vacuum system

Vacuum pump: 2.2Kw,1 set;

Vacuum degree = 0 ~ 0.075 Mpa

Adaptor

Material: #40steel Chrome plated40, inner convergent flow type

Connection method with die: clamping block + bolt

Pressure melt sensor and thermocouple

Main electric cabinet

Inverter: ABB; Contactor : Schneider; Air Switch :LS;

Relay: Omron; Temperature controller: Omron

Self-protective system

Over current protective of motor

Over pressure protective of screw

Outer size and weight 3800×1500×2410mm 2200kg

This is the die mould of the Solid-wall Pipe Extrusion Machine twin pipe extrusion machine line.

specifications is as below parts:

Include calibration sleeve

Mould type: dual

Material: Made by 40Cr ; Inner surface polished

Diameter spec: Ф20, 25, 32, 40

Wall thickness: Providing by customer

Remark: According to customer requirements, it is possible to provide water supply pipe.

Solid-wall Pipe Extrusion Machine twin pipe extrusion machine line is as below:

Dimensions: Length: 5600mm ; Two chambers

Vacuum pump: 1.5Kw x 2 units

Water pump: 3Kw x2units

Three direction adjustment:

Forward and Backward moving:0.75 KW motor

Range: ±1000mm

Up and down: left and right manually adjusted

Range: Up and Down: ±150mm

Leftward and rightward moving: ±50mm

Tank material: STAINLESS STEEL

Electric cabinet: With water temperature control system

Solid-wall Pipe Extrusion Machine twin pipe extrusion machine line Haul off and cutting unit (chain wheel driving)

HAUL-OFF (for Dual pipe):

Haul off unit (2 belts) for dual pipe

Effective haul-off length: 1100mm

Claw width: 80mm

Maximum hauling speed: 12m/min

Main motor: 2 units AC motor, controlled by inverted Hitachi or Schneider Each 3 KW

Speed control: independent for each haul off.

CUTTER (for Dual pipe):

Integration installed in monobloc system (haul-off and cutting).

Length count: coder

Cutting saw: steel alloy, specific for cutting U-PVC pipe.

Equipped with rubber clamping block for accurate cutting.

Motor power: 1.1Kw X 2 pieces

Equipped with a closed dust-collector

With scrap collecting device

Possibility of manual operation

Solid-wall Pipe Extrusion Machine twin pipe extrusion machine line Stacker.

Pneumatic discharging

Length: 5000mm

Up and down: ±90mm

We also offer some spars parts for the Solid-wall Pipe Extrusion Machine twin pipe extrusion machine line.

below is the list for your reference:

No. Name Qty. Used for

1 Big spanner 1 set Extruder

2 Oil seal of high-speed axis of gearbox 1 piece

3 Nylon pin for axial connector 1 piece

4 Thermocouple 3 sets

5 Rubber block 15 pieces Haul-off

6 Electromagnetic valve 2 pieces

7 T air linker 5 pieces

8 Sealing bar 10m Vacuum tank and spray cooling tank

9 Sprayer 15 sets

10 Small contactor 2 Electrical cabinet

11 Button and switch 2

12 Relay 2

Also below is some information of the businees iterms for your reference:

4.1 Technical documents

All the symbols on the equipments should be in English. Seller is responsible to provide general layout plan, electric plan, installation direction, and manual book in English to Buyer on time.

4.2. Arrangement for inspection, installation and testing work

a. After all machines are delivered to customer's factory; Buyer is responsible for all preparation work, e.g. electricity supply, water supply, labors and cranes, etc.

b. ACEMIEN will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer's factory.

c. The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD60 per day for each engineer.

d. Engineer will give free training lessons to labors in buyer's factory.

e. If buyer doesn't request installation and commissioning by Seller's engineer in 4 months since date of bill of lading, which to be accounted all the machines has been successfully tested by buyer.

4.3. Quantity and quality guarantee

a. Quantity/Quality Discrepancy to destination port during transportation:

In case of quality/quantity discrepancy to destination port in transportation, customer should file claim within 30 days after the arrival of the goods at port of destination. Insurance company and shipping company will be responsible for any discrepancy of the goods caused by shipping company and other transportation organization and/or post office.

b. Guarantee period and after-sales services: 12 months since date of bill of lading

During this guarantee period, ACEMIEN will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, ACEMIEN will provide the buyer spare parts at cost price.

c. Long-term service:

ACEMIEN will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide.

4.4. Validity: Three months since quotation date.

We thank you for your inquiry and would be pleased to receive your order soon.

Jiangsu Acemine Machiney Co.,Ltd is Jiangsu province, China. Our factory is professional produce the extrusions for the plastic pipes, the roofing tile machine, the plastic profile .

If you need any of the extrusion machines, please feel free contact me, please!

My name is Karry, please feel free contact me, please!

Whatsapp: +86 18913298068

Phone/ Wechat : +86 18205059535

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23