Plastic Machinery Synthetic Hair/Man-Made Hair Filament Wig Yarn Drawing Extruding Machine

Quzhou Sun Winjer International Co., Ltd / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJ-75/80/90 Output 50-150kg/H Power 380V/3/50Hz Application of Final Production Rope/Net/Broom/Brush Screw Size Single Screw Transport Package Seaworthy Package Specification SGS Trademark ZHUOYA MACHINERY Origin Qingdao, Shandong, China HS Code 84772090 Production Capacity 200 Sets/YearProduct Description

Plastic Filament Extruding MachinePRODUCT DESCRIPTION:

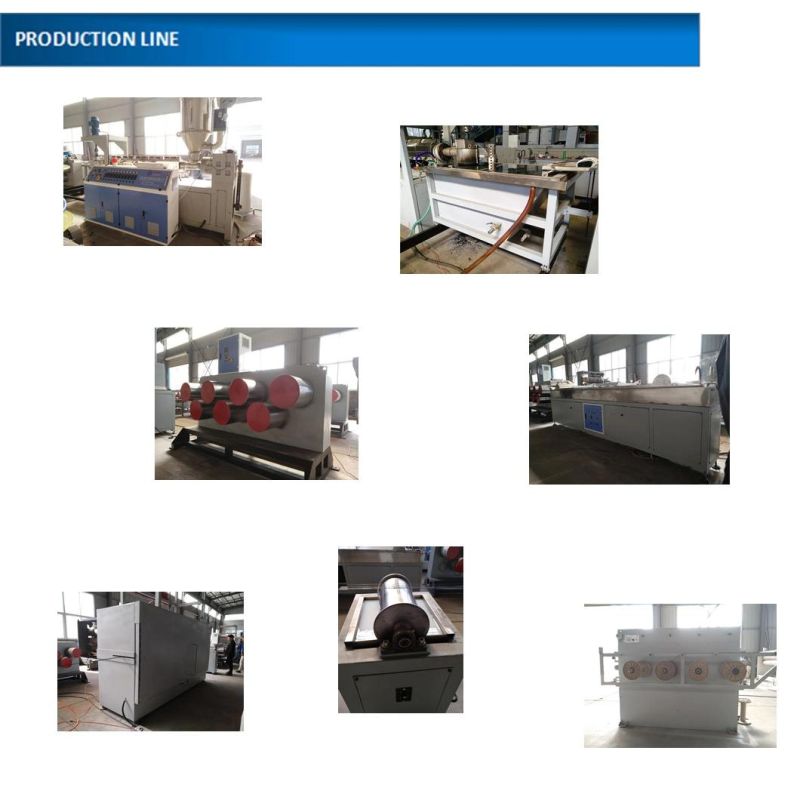

1.Constitution:The production line consists of dehumidifying and crystallizing system, extruder, screen changer, Meter pump, mold, haul-off, oven, and winder, etc.

2.Production Process:Material→ Dehumidifying and Crystallizing → Extruding → Filter→ Metering→ Mold → Cooling→ Haul-off →Water heating→ Haul-off→ Water heating→ Haul-off → Glazing → Shaping → Haul-off→ Winding

MAIN FEATURES:

1.Eco-friendly and Extensive Use: With 100% recycled PET bottle flakes, PP pellets, or PE pellets to produce high quality synthetic hair or eyelash monofilament.

2. Mature Technology and High Performance: New technology, hot wind cycles to dry, increase the viscosity of the bottle flakes material; secondary stretching, increase the tensile strength and elongation, the belt tension reaches more than 10000N

3.Energy Conservation: Precise and energy saving temperature control system, power saving, low noise, low input and high yield.

ELECTRICAL CONFIGURATION:

1) Main motor frequency controller: ABB

2) Temperature controller: OMRON

3) AC contactor: Siemens

4) Thermal overload relay: Siemens

5) Breaker: CHINT or according to customer requirement

TECHNICAL PARATETERS

| Power supply | 380V,3 phase,50HZ |

| Raw material | PET/PP/PE/PVC/PBT |

| Diameter of final product | 0.05-2.5mm |

| Capacity | 50-150kg/hour |

DIFFERENT MODELS

| Model | Filament Dia. | Production capacity | Total Power |

| SJ-75 | 0.05MM-2MM | 50-85kg/h | 80KW |

| SJ-80 | 0.05MM-2MM | 70-120kg/h | 90KW |

| SJ-90 | 0.05MM-2MM | 85-150kg/h | 100KW |

Our Service:

1. Pre-sale service:

- Provide market research information and consultation

- Help customers make project planning and systematic analysis

- Maximize customer's satisfaction

- Achieve the mutual benefits of our customers and our company

- Install products and test products for customers

- Provide the formulas and technologies of relevant products and the information of chemical materials manufactories

- Provide technical direction according to customers' requirements

- Provide technical training for clients' employees

Q1: If I need more information, how to contact you?

A:Send me your demands, we will send back detailed machine specifications with working video.

Q2: How to buy your machine?

A: We send detailed machine quotation to you, if you are satisfied, we will make PROFORMA INVOICE for you. Payment terms: 30% deposit, after machine testing good, 70% before shipment.

Q3: What about warrant?

A: We have one-year warranty.We will provide the spare parts for free except the malfunction caused by your incorrect operation.

Q4: How can I believe your factory and company?

A: You are welcomed to ask authority to visit our factory and machine, we are real factory.

Q5: Do you have other service?

A:We can send engineer to your factory to install the machine and offer training. Each year, if we have machine technical improvements, we will inform customer.

Q6: Where is your factory located?

A:Our factory is in Qingdao city which has the world famous port. If you want to visit our factory, we can come to pick you up.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23