2000L/H, Middle Homogenizer for Making Milk

Guangzhou Junjie Cosmetics Packaging Co., Ltd. / 2022-07-05

- Condition:New

- Customized:Customized

- Voltage:380V, 50Hz, 3 Phase

- Composition:Mixing Machine

- Processing Material:Fruit, Juice

- Process:Thermal Processing

=== Base Info ===

- Model NO.:GJB2000-25

- Name:2000L,H, Middle Homogenizer for Making Milk

- Model:Gjb2000-25

- Material:Stainless Steel 304

- Pressure:25MPa

- Flow:2000L,H

- Weight:1150kg

- Factory:Yes

- Power:15kw

- Transport Package:Plywood Case for Homogenizer

- Specification:115x95x133cm

- Trademark:CHANGGUAN

- Origin:Changzhou

- HS Code:8479820090

- Production Capacity:300sets,Year

=== Description ===

Certification

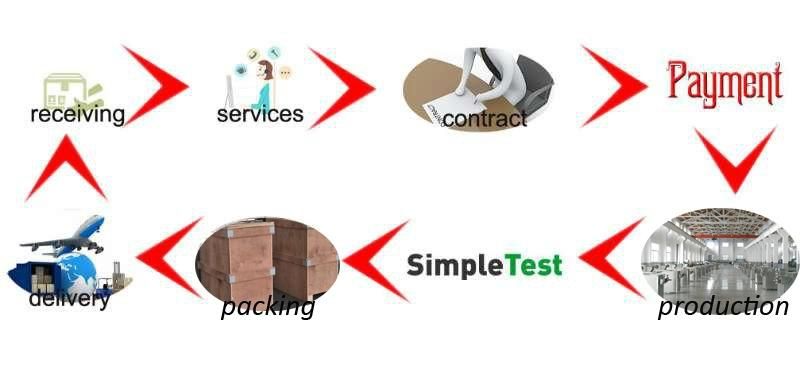

Service

Product

Feature

This machine are features with good design,convenient operation and simple maintenance,and safety.

1)Low noise:Noise of transmission is lower than noise of motor. The pointer of pressure meter is steady, and also the range of swing of pointer is less than 2M Pa.

2)Smashing granularity is between 0.1 micron to 0.2 micron, and their average size≤1 micron.

3)Sealing material can work under less than 150ºC, and the parts touching material is made of stainless steel which can stay up to the acid and alkali. All of valves and plungers are made of special material, so they are durable and inexpensive. The bearing is also durable because it is made of special alloy material, which is the more friction, the more hardness.

4)Lubrication of homogenizers is credible, and it only need changing oil the first time when work 800 hours to 1000 hours, since then it need to be changed oil per year later

5)The higher the pressure the finer the material the more uniform particle size, 30MPA the following models, mainly for liquid - liquid emulsification. Pressure of 30MPA above, on the liquid - solid dispersion of liquid into play when the pressure most of the material up to 60MPA reach 2μm particle size less than when the material reaches 80MPA more obvious when the role is mainly used for ultrafine particles broken Materials to achieve the following general 1μm. As to 100MPA above, can be produced more subtle particles, some of the material particles after repeated high pressure homogenization, 0.1-0.5μm can be prepared the following no-grain materials.

Delievery

Producting Perfect Product, Serving Customers Satisfactory.

Producting Perfect Product, Serving Customers Satisfactory.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23