Hot Cutting/Die Face Cutting PVC Compound Extruder/Granulating Line

Poyang Tianli Diamond Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. GF65 Engagement System Full Intermeshing Screw Channel Structure Non Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Non-Computerized Electrical Componenets Siemens Color Customized Guarantee Period 1 Year Manufacturing Time 30 Days Cutting Die Face Cutting Cooling by Blower Granules Rigid and Soft PVC Capacity 250kg/H Delivery by Shipment Pack by Film and Wooden Box Transport Package Plastic Film/Wooden Box Specification 250KG Trademark Yusheng Origin Zhangjiagang City (Near Shanghai), China HS Code 84778000 Production Capacity 10 Sets Per MonthProduct Description

Machine name: Hot cutting/die face cutting PVC compound extruder/granulating line1. This PVC granulating machine is composed by a conical twin-screw extruder and the correspondingly pelletizing downstream equipment, it is suitable for the pelletizing of PVC, PE raw materials with wood powder or other additives.

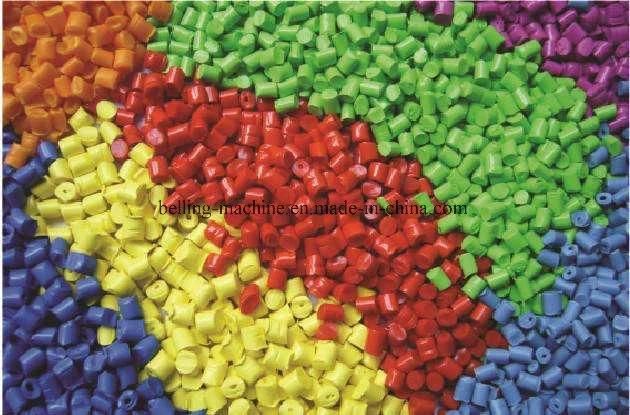

2. The pellets produced by this machine is evenly, solid, elegance.

3. The pelletizing downstream equipment is the die face cutter, air transferring unit, vibration separating and cooling unit. This pelletizing downstream equipment has the features of high automation and high production efficiency.

4. The screw and barrel, made of 38CrMoAlA, are made through smithing, tempering, double aging, nitriding treatment. Differences from others: Screw edge is tempered after rough finish with good harden ability, and double aging reduce efficiently stress. Meanwhile, through accurate processing, phases of the screw edges have small error. The barrel and screw have high universal property. The structure of screw is different to different materials.

|

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23