Tire Recycling to Oil Pyrolysis Machine

SILVERSTAR MANUFACTURING CO., LTD. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

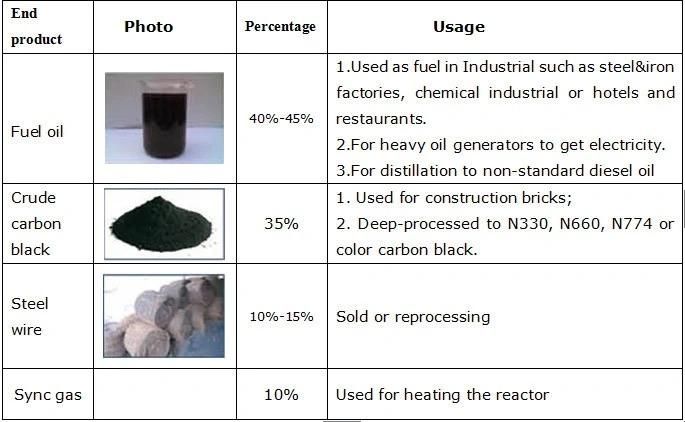

Model NO. XY-9 Manpower 1-2workers Cooling Method Cold Water Raw Material Waste Plastics, Rubbers and Tires Fuel Oil 40-45% Carbon Black 30-35% Steel Wires 12-15% Sync Gas 3-5% Weight 90-100tons Power 100kw/H Transport Package Containers Specification CE, ISO, SGS Trademark Shangqiu jinpeng Origin Henan, China HS Code 8419409090 Production Capacity 80 Sets Per MonthProduct Description

Brief introduction:

1. CE&ISO9001&ISO14001

2. High oil yield to 40%-45%

3. Operated-easily

4. Environmental friendly

5. Longer lifetime

6. Energe-saving & time-saving

7. Both manual and automatic satety devices

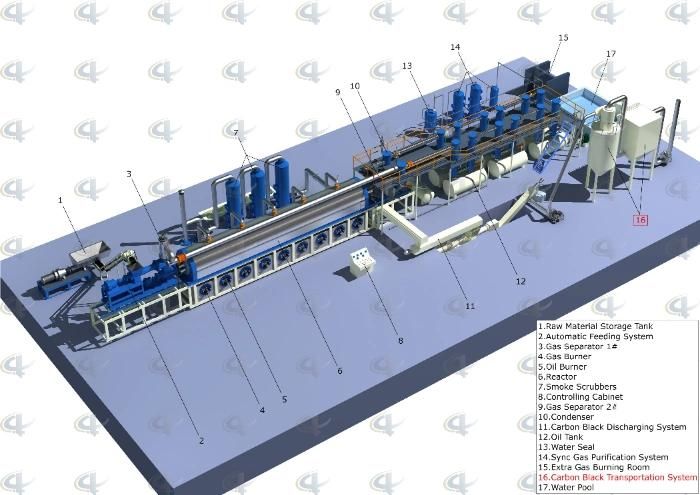

1.3D Figure of the Continuous Pyrolysis Plant

2. Main Parts and Function:

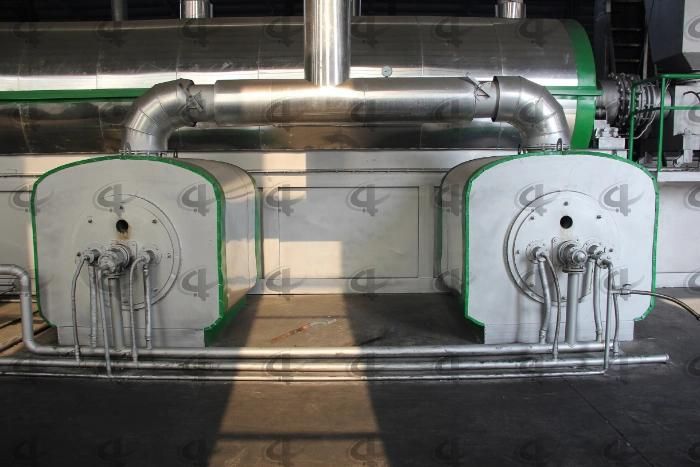

(1).Heating system

---two heating rooms and indirect heating.

(2).Cooling system

---12 new design condensers to convert the oil gas into oil.

(3).Waste gas purifying system

---its function is to remove the acids, bad smell and dust from the waste gas, so the gas will be more clean and environmental friendly.

(4).Smoke purifying system

---its function is to remove the acids,bad smell and dust from the smoke, so the smoke into the air will be clean and no pollution.

(5).Carbon black discharging system

---we adopt the whole sealed automatic discharging system to ensure no carbon black flying out,so the whole process is no pollution at all.

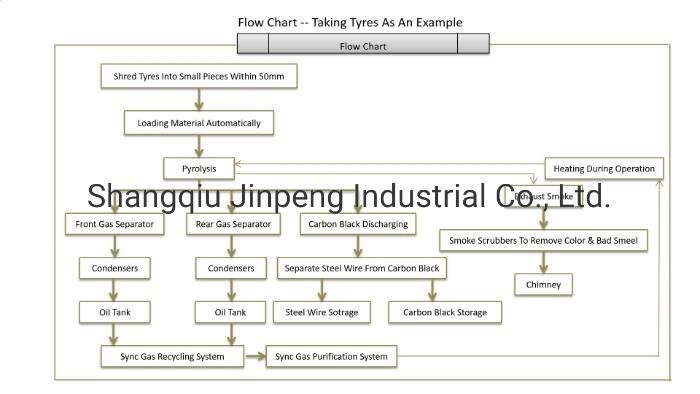

3.Flowchart of Continuous Pyrolysis XY-9-P

4.Outstanding Features

(1).You just need preheat at the first time when the machine start producing.And then the machine can produce lasting for 20 days without stop. Because it can use the waste gas to heat the chamber,no need other energy.

(2).The most capacity can reach 25T/D, much bigger than other kind of plant.It is fully-automatic and fully-continuous.

(3).New design of vertical condensers.you can get high oil yield,good oil quality,high profit.

(4).The carbon black and steel discharging is easier.The carbon black and big size steel can discharge when the chamber is hot needn't cooling down.Very save energy.

(5).Low requirement on the raw materials,no need tiny granule, 10cm pieces acceptable for smooth running

5.The Output Percentage and Usage (tyre for example)

Packaging details:

a.By Sea

b.Delivered by 4-5HQ & 1 FR container

c.About 50 days after the first deposit

d.Use the exported package standard to avoid any damage in transportation.

Our Services1.Quality warranty period: One year warranty for the reactor of the pyrolysis machines,and lifetime maintenance for complete set of machines. pay the double air tickets, accommodation and food.

2.According to the requirement of the buyer, our company sends engineers for installation and commissioning in buyer's site including the training of skills of buyer's workers on operation, maintenance, etc.

3.Supply layout according to buyer's workshop and land, civil works information, operation manuals, etc. to the buyer.

4. For the damage caused by the users, our company provides the parts and accessories with cost price.

5. Our factory supplies the wearing parts with the cost price to clients.

Company Introduction

Shangqiu Jinpeng Industrial Co., Ltd, which was founded in 1985, is the first professional institute in recycling and utilization of solid wastes (waste rubber, waste plastics, waste tyres, etc.) in China, It is also a technology innovative demonstration enterprise involving scientific research, manufacture and sales together. Now the company covers an area of 113,220 square meter. And its annual sales amount are about 300 sets and total sales amount is 180 million RMB per year.

Founded in 1985, our company has achieved great progress in waste recycling area. Nowadays, our company has owned 14 national patents and a provincial engineering research center. And ourproducts has achieved CE, SGS, ISO, BV, BUV certifications.

Up to now, our products include Pyrolysis Plants for waste rubber, plastic and tyres, normal pressure Distillation Plants for waste engine oil, crude oil and the Carbon Black Deep-process Machines.

Due to the unique advantages, our machines are widely used in China and overseas, such as Poland, Austria, Albania, Turkey, Republic of Korea, Thailand, India, Africa countries, etc.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23