Automatic Pinnis Ball Encrusting Machinery

CHANGZHOU JLON COMPOSITE CO., LTD. / 2022-07-05

- After-sales Service:Online Technical Support

- Warranty:12 Months

- Certification:CE

- Power Source:Electric

- Process:Protein Ball, Energy Ball, Fruit Ball

- Automatic Grade:Automatic

=== Base Info ===

- Model NO.:P160

- Application:Candy, Chocolate, Donut, Protein Ball, Energy Ball, Fruit Ball

- Customized:Customized

- Model:P160

- Capacity:60-100 PCS,Min

- Product Diameter:10-50mm

- Power:2.55kw

- Voltage:220V,50Hz

- Weight:380kg

- Dimension:2400*860*1300mm

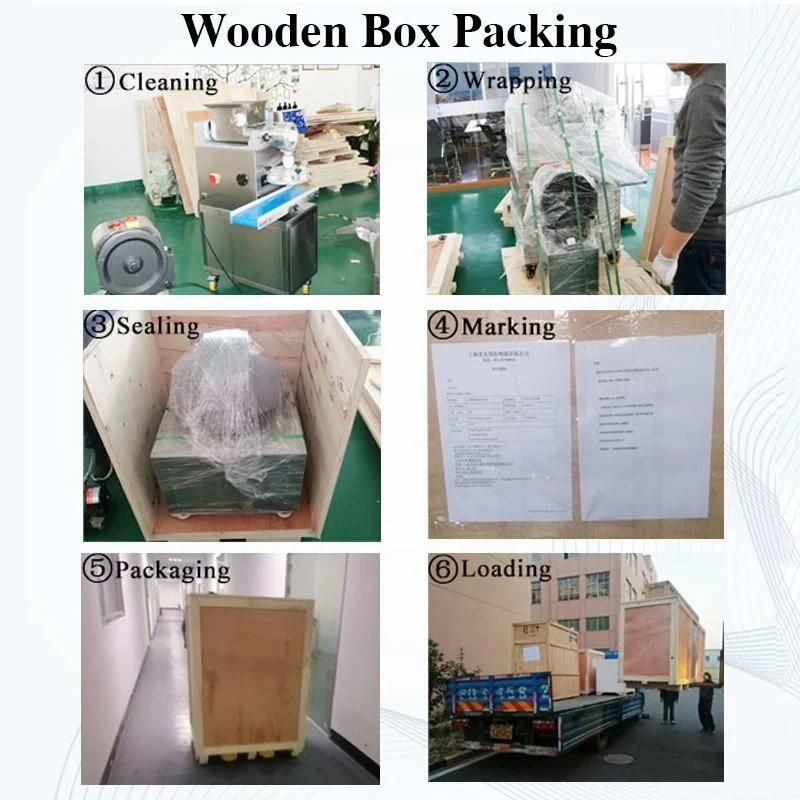

- Transport Package:Wooden Case

- Specification:2400*860*1300MM

- Trademark:IPAPA

- Origin:Shanghai, China

- HS Code:8438100090

- Production Capacity:500 Sets,Year

=== Description ===

Overview

Product DescriptionDetailed PhotosProduct Parameters

Packaging & Shipping

Company Profile

After Sales ServiceFAQWhat size range can the protein energy ball machine make?

Normally, the protein energy ball machine can make ball diameter from 10mm to 50mm, we can customize bigger size if customer require, for example, we customized a 65mm diameter ball for our Canadian customer to make energy ball.

What is the lightest weight your energy ball machine make?

Normally our energy ball machine can make food weight range from 10g to 250g, the lightest weight we ever made is 6g.

How many moulds and rolling wheel do you supply for the energy ball making machine?

One machine has one piece of nozzle mould and rolling wheel. If customer need extra ones, we need to charge cost price.

What if I have more than one ball sizes, can your energy ball rolling machine make it?

Our energy ball rolling machine has one rolling wheel. If customer has more than one ball size and ball diameter range is above 2mm, we suggest customer to take an extra rolling wheel. Most of our customers have only one ball size, a few of them have two sizes.

For the energy ball roller, What is the material for the rolling wheel? Do you have cheaper rolling wheel if many ball sizes?

The rolling wheel for our energy ball roller machine is aluminum materials with teflon coated. It is a little expensive, but this material is more stable and strong in rolling and more environmental for food production. There is a cheaper rolling wheel made by plastic, which our company don't manufacture.

Can your bliss ball making machine available for extruding chocolate chips or granules?

The bliss ball making machine can hold chocolate chips or granules with size within 4mm, and for bigger chocolate chips, it will easily break and melt during the extrusion. Also bigger granules will be hard to extrude. The chocolate chips and granules have no affection on our bliss ball rolling machine. Our bliss ball machine australia is sold very well because of it's good quality.

What materials can you coconut flake machine coat?

Our coconut flake machine can coat coconut flakes, sesame seed, fruit seeds, smashed nuts, chocolate chips, grounded powders, etc.

Can your energy bites making machine make center filling or stuffed ball? If yes, what kind materials can be used for filling?

Our energy bites making machine can make center filling ball, the filling materials can be jam, peanut butter, chocolate paste, fruit paste, chocolate liquid, etc.

What is the outside casing and center filling ration for your energy bites extruder machine?

The outside casing and center filling ration is 1:9-10:0.

Can your protein bites making machine make bar shape? Do we need to add extra machinery?

The protein bites making machine can make bar shape product by adding a extra cutting machine which is separated controlled by PLC system with touch screen.

What if my material is sticky or too hard? How to judge?

The protein ball making machine is only suitable for soft and medium hard mixture, too sticky mixture will stick to shutter and conveyor belt. Then how to budge the hardness and viscosity ?

We have more than ten years experience on the protein ball machine, we have tested thousands of customer's materials. Firstly, We can basically judge by seeing ball photos; Secondly, we can judge by watching customer's mixture videos. It must be fresh new made mixture, normally we require customer to squeeze the mixture by hand, so we can judge the hardness and viscosity at the same time. If it's a hard dough, it will be hard to squeeze by hand, If it's a sticky mixture, it won't fall out of your hand or it won't fall out of your belt. Thirdly, we require customer to send us their main material ration list, detailed formula will be prefered. Finally, if we still can not judge, we shall require customer to send us their materials by air, we test here in our factory.

Can the protein ball extrusion machine, protein ball roller machine, coconut flake coating machine be connected to be a full automatic line?

Yes, The three machines can be connected together one by one, each machine is separated, convenient to move and control.

What other machinery is needed for the ball production?

The energy ball machine only requires electricity, no other machinery and power source is needed.

Can we just buy the energy ball roller only?

Customer can buy the energy ball roller machine only, But without the dough extruder, customer has to make each pieces of dough by hand, then take each pieces t energy ball rolling machine by hand. This way will waste customer lots of labor and time. Besides, cutting each piece of dough can't guarantee the dough weight, customer has to weight each piece of dough one by one, it is not a cost effective solution. In a word, We suggest customer to take the energy bar extrusion machine together.

Is the coconut flake coating machine a necessary equipment? Can we add it later in future?

The coconut flake coating machine is not a necessary equipment. Customer can add it later in future. The protein ball extrusion machine and protein ball rolling machine are the necessary equipment. If customer has requirement for coating, he can achieve it by manual operation.

Do you have a bigger coating machine?

We do have a table type coating machine, it is much bigger capacity which can be used for several energy ball making machines.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23