Factory Low Cost Potato Chips Machine French Fries Processing Line Machine

Gidea Packaging Enterprise Limited / 2022-07-04

- Certification:SGS

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Chips

- Customized:Customized

=== Base Info ===

- Model NO.:WS

- Material:Food Grade Stainless Steel

- Quantity:8 Sets of Machines

- Transport Package:Export Wooden Cases

- Specification:6 CBM

- Trademark:GMEC

- Origin:Zhengzhou

- Production Capacity:50 Sets Per Month

=== Description ===

Basic Info.

Model NO. WS Material Food Grade Stainless Steel Quantity 8 Sets of Machines Transport Package Export Wooden Cases Specification 6 CBM Trademark GMEC Origin Zhengzhou Production Capacity 50 Sets Per MonthProduct Description

Factory Low cost Potato Chips Machine French Fries Processing Line Machine

1.Description:

Fried potato chips is one kind of snack processed from fresh potato after washing, peeling, slicing, frying and flavoring. It keeps the special delicious flavor of roasted potato on one respect and has the characteristics of rich nutrition, delicious, convenient and so on, thus won the flavor of the consumers.

2. Operation procedure:

Washing and peeling--cutting--blanching--dewatering--frying--de oiling--flavoring--packing

3. Brief introduction for the potato chips production line:

(1). Fresh potato cleaning and peeling machine

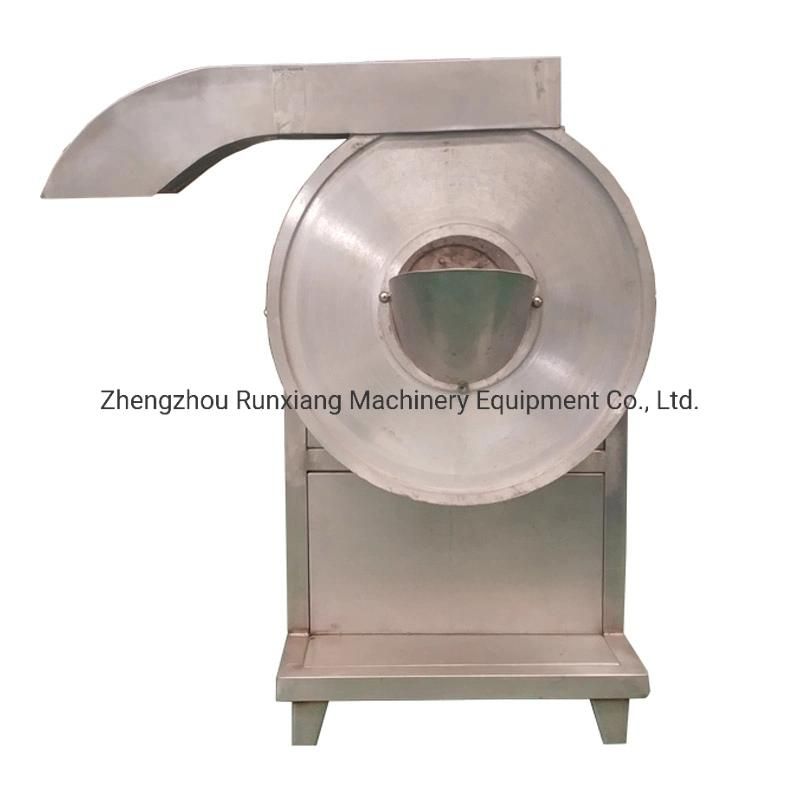

(2). Potato slicer/chips making machine

(3). Blanching machine

(4). Dewatering machine

(5). Frying machine

(6). De-oiling machine

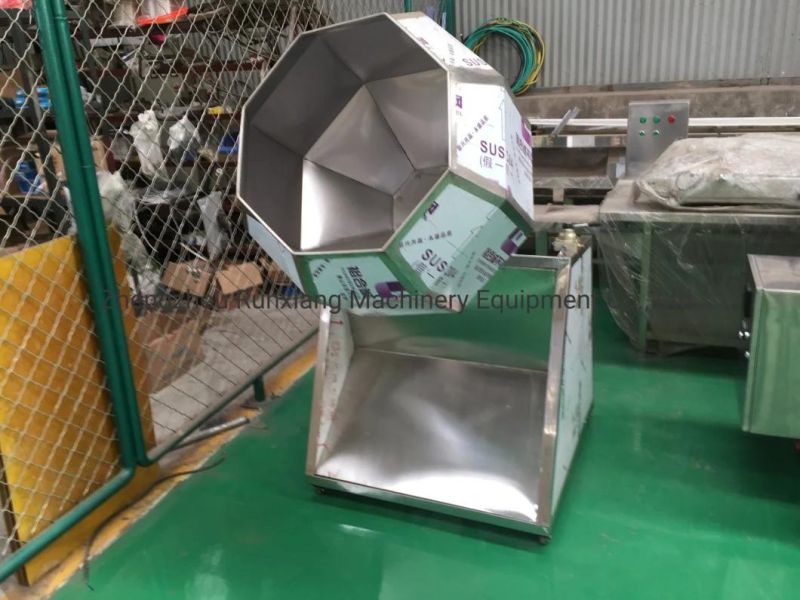

(7). Flavoring/seasoning machine

(8). Potato chips packaging machine

4, All materials of our machines are 1.5mm thickness 304 Stainless steel.

5, Now we have capacities as below:

30-40kg/h, 70-80kg/h and 150kg/h. 500kgh, and also can make the special capacity according to your needs.

| Machine name | Power | Dimension |

| Washing peeling machine | 1.5kw | 700*630*950mm |

| Potato cutter | 1.1kw | 900*850*1000mm |

| Blanching machine | 24kw | 1000*500*1000mm |

| Dehydrator | 1.5kw | 1000*600*740mm |

| Fryer | 36kw | 1200*1000*1200mm |

| Deoiler | 1.5kw | 1000*600*740mm |

| Seasoning machine | 1.1kw | 1150*800*1300mm |

| Packing machine | 1.5kw | 800*500*1000mm |

This potato chips production line is the best choice for making potato chips with low investment and power consumption. This whole line is made up of potato washing peeling machine, potato cutting machine, blanching machine, dehydrating machine, frying machine, deoiling machine, flavor mixing machine and nitrogen filling packing machine.

1.Peeler: cleaning and peeling process at one time, high efficient and low consumption.

2. Cutter: cut into strip,flake and julienne shape, adjustable cutting size

3. Blanching machine: do rinsing and color protection of the cut potato chips.

4. Dehydrator: centrifugal dehydration, reduce the time when drying, and improve the taste of the potato chip.

5. Fryer: keeps the potato chips quality and taste.

6. De-oiling: use the centrifugal, overcome the shortcoming of botheration.

7. Flavor Machine: make the potato chips turning even, use the spray type to add the seasoning, not easy to break.

8. Vacuum package machine:when packing, put into nitrogen, can avoid break of the potato chips.

We also have full automatic potato chips making machine line(150kgh,300kgh,500kgh):

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23