WPC PE Wood Plastic Terrace Decking Profile Production Line with Extrusion Machine From ...

CHINA GTL TOOLS LIMITED / 2022-07-04

=== Base Info ===

=== Description ===

WPC Profile(terrace decking) Extrusion Line

---Features at a glance--- Equipment advantages:

Equipment advantages:

1. The parallel twin screw extruder is used to mix the wood and plastic, and get good homogeneous melt . Main motor 37kw, output 100kg/hr.

2. Wood fiber can be 65% in the WPC products due to the good mixing effect, so the cost of

WPC product is low

---Product Specifications---

---Product Details--- Coincal Twin Screw Extruder

Coincal Twin Screw Extruder

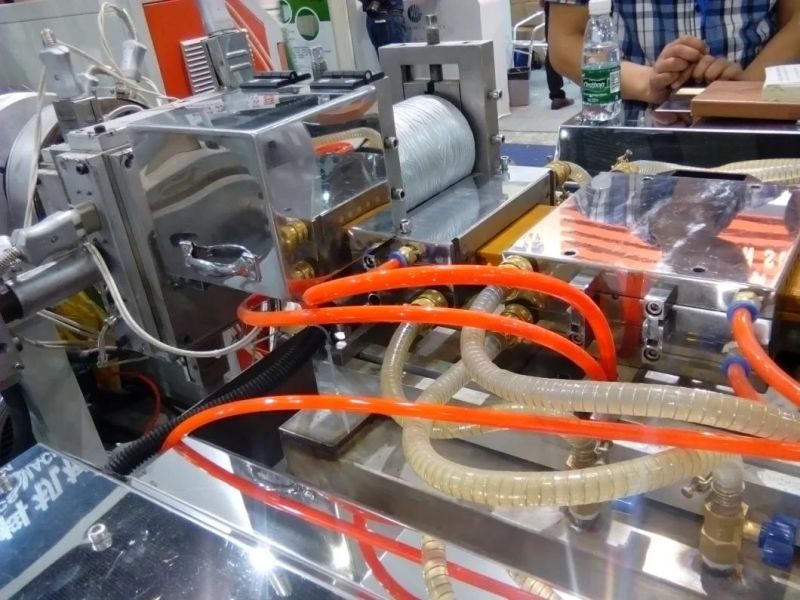

The extruder dopting specially screw designs according to PE-WPC character. Imported famous brands AC inverter makes the rotation speed stable to ensure the main extruder and accessory machines move synchronously Profile mould

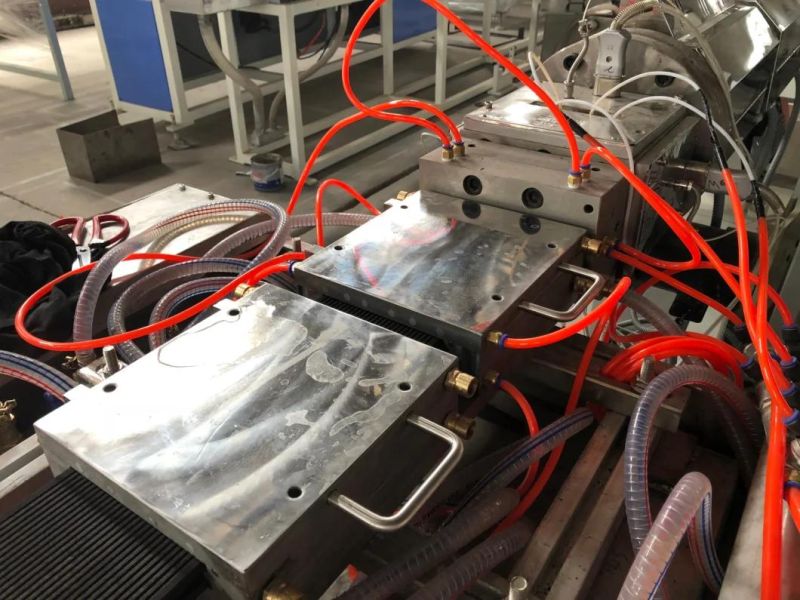

Profile mould

The mould is making by material 3Cr17, it includes the die head parts, vacuum calibrator parts, water cooling tank parts

Vacuum calibrating table

According to the material properties, adopting powerful turbo cooling system, easy to achieve satisfactory cooling effect. According to different moulds and different customer requirements, the vacuum calibrating table can be optional as 4m, 6m.

Cutting machine

Cutting machine

The moving speed of the cutting unit is synchronized with hauling speed. Through prseting,the cutting unit is capable for automatic cutting with fixed length. Dust recycling device is also equipped. Stocker

Stocker

The stocker with length 4m, the turnover table is controlled by cylinder, turnover controlled by Limit switch.

---Company Profile---

---Company information---

Qingdao Weier Plastic Machinery Co.,Ltd ,the professional manufacturer of plastic machines,which is engaged in macromolecule science,is the director member of WPCC (plastic & wood production council of Chinese plastic community). We cooperated with many domestic universities to develop special plastic machines to meet domestic and foreign customer's requirement .

Now we become the test and industrialization centre of plastic engineering technology research institute Qingdao Science and Technology University. At the same time we bring in and absorb advanced processing engineering of foreign plastic machines.To realize chain service of technics and machines.

We have more than 30 machine lines running in China market; Welcome to visit us, and also can show the machine line running in client's factory.

---Why choose Weier---

- We are engaged in macromolecule science, is the director member of WPC (plastic & wood production council of Chinese plastic community)

2.We cooperated with many domestic universities to develop special plastic machines to meet domestic and foreign customer's requirement.

3.We become the test and industrialization centre of plastic engineering technology research institute of Qingdao Science and Technology University.

4.we bring in and absorb advanced processing engineering of foreign plastic machines to realize chain service of technics and machines.

5.We have experiences in this field since 1980s

6.We have our production bases for WPC and plastic product in China with large scales, which shows our machine's production power

7.We have strong technical teams and cooperate with China scientific institution to develop, improve and test our machine, to ensure what customers get are the most reliable machines from China.

8.We select the most reliable mechanical and electrical parts for our machine with all famous reliable brands, with European CE certificated.

9.We put our heart into every business with aim of long term cooperation.

10.We have perfect service system-- Our president is devoting himself to pre-sale, on-sale and after-sale service. WEIER JUST DO WIN-WIN BUSINESS!!!

---FAQ---

A:1)30% of total amount paid by TT as advance, then the seller start production

2)after the machine is finished ,buyer come to test the machine in seller's factory ,

and then pay the 70% balance by TT or irrevocable L/C at sight . Then seller ship the machine.

Q2.How long is the delivery time?

A: For standard machines, it would be 30 days; For non-standard machines and customized machines according

to client s specific requirements, it would be 45 days.

Q3.Do you arrange shipment for the machines?

A:Yes,for FOB or CIF price, we will arrange shipment for you.

Q4.How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List,

Commercial Invoice, B/L, and other certificates as required by clients.

Q5.What's your after-sales service ?

(1)The supplier provides service manual and maintenance instruction of main electric appliances, limb, usage manual of equipment. We also supply water, electricity, gas of equipment and installation drawing. (2)The supplier is responsible for installation, debugging and training, but the air tickets, insurance, eating, housing and every day 100 USD for each engineer will be born by the buyers. We will realize guarantee of repair; replacement and refund of substandard products within one year after the machine leaves factory. And half a year for electric parts. Fittings of the machine will be supplied at preferential price after one year.

Q6.What's your warranty?

We will realize guarantee of repair; replacement and refund of substandard products within one year after the machine arrived in customer's factory (except destroyed by buyers' wrong operation). We guarantee the material of screw & barrel (guarantee without normal abrasion). And half a year for electric parts. Fittings of the machine will supply at preferential price after one year.

Contact Person:Yuriy Yu 0086 15908964630

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23