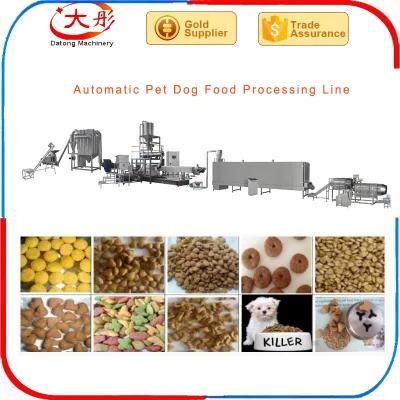

Factory Supply Pet Dog Food Making Machine

Ningbo DSW International Co., Ltd. / 2022-07-05

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Dog, Fish, Cat

- Feed Type:Grain

- Customized:Customized

=== Base Info ===

- Model NO.:SLG100

- Material:Stainless Steel

- Electric Parts:LG, FUJI, Omron etc

- Line Szie:15*4*4

- Motor Speed Comtrolling:Delta Inverter

- Motor Brand:Siemens China Brand

- Food Types:Cat Dog Food

- Manufacture:Jinan Datong

- Raw Materia for Food:Corn Wheat Starch Meat ....

- Production Name:Factory Supply Pet Dog Food Making Machine

- Transport Package:Woodcase

- Trademark:Datong

- Origin:Jinan

- HS Code:8438800000

- Production Capacity:400-550kg,H

=== Description ===

Basic Info.

Model NO. SLG100 Material Stainless Steel Electric Parts LG, FUJI, Omron etc Line Szie 15*4*4 Motor Speed Comtrolling Delta Inverter Motor Brand Siemens China Brand Food Types Cat Dog Food Manufacture Jinan Datong Raw Materia for Food Corn Wheat Starch Meat .... Production Name Factory Supply Pet Dog Food Making Machine Transport Package Woodcase Trademark Datong Origin Jinan HS Code 8438800000 Production Capacity 400-550kg/HProduct Description

Nigeria floating fish feed pellet machines

1.Floating fish feed pellet machine can produce a premium quality special koi food, goldfish food, tropical fishes food, dog food, cat food, as well as laboratory dog and monkey food. They all are sold at home and abroad and win high praise and favorably commented from customers. This fish feed machinery can do floating and sinking fish feed. fish feed machine, pet food machine, fish feedstuff machine, fish food machine.

2.Raw Material:corn flour,wheat flour,low temperature,soya flakes meal,rice ,wheat bran,annexing agent,etc.

3.Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

4.Gold supplier Aquarium fish food machine Features:

1.Datong Company fish feed extruder machine is used to produce the food with novel shape, particular taste and color.

2. Scientific nutrition combination catches up the trend of the market.

3. In this line, you will see the advanced technology of JINAN DATONG machinery. With simple operation, accurate parameter control, the products can be finished in the stipulated temperature, pressure, humidity and time.

4. Owing to the reasonable design, special materials ,the stability, repairs can be guaranteed and ensured.

5.The various shape and taste must meet the different requirements.

5.Fish food processing line Process chart:

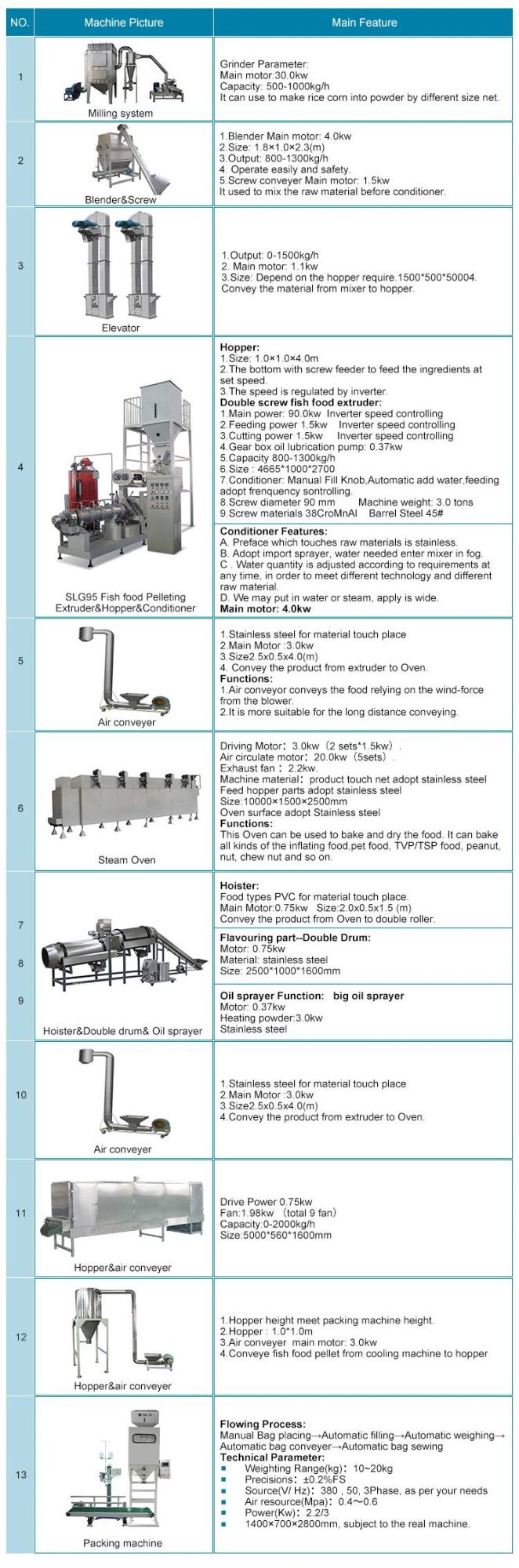

Blender→elevator→Storage→Conditioner→Steam Fish food extruder→Air conveyer→Steam Dryer→Hoister→oil sprayer→Double Drum→Cooling conveyer→Sifter→Packing Machine.

6.Pet food machine model:

| Steam Model | Install power | Consumption | Main Power | Capacity | Diemension |

| SLG65 | 35.0kw | 22.0-30.0kw | 22.0kw | 120-200kg | 15*2.5*4.0M |

| SLG70 | 48.0kw | 25-40.0KW | 30.0kw | 250-400kg | 27*2.5*4.5M |

| SLG70-W | 35.0kw | 40.0-50.0KW | 45.0kw | 300-500kg | 27*2.5*4.5M |

| SLG85 | 75kw | 50-60kw | 55kw | 500-600kg/h | 35*3*4.5m |

| SLG90-w | 75kw | 50-60kw | 55kw | 800-1200kg/h | 35*5.0*5.0 |

| SLG100-W | 90 | 80KW | 80KW | 1500-2000kg/h | 40*10*10m |

7.Datong Company Info

Jinan Datong Machinery Co., Ltd is a professional food machinery manufacturer in Jinan city shandong province China.Our company congregates an exceptional food machine engineering team, personal customer service center and highquality manufacturing capabilities have evolved exponentially,We are working hard on explore constantly not only in the research of extrusion technology, but also in food technics to benefit our clients producing newfangled food in their markets. It making us become one of the preeminent providers of reliable extrusion equipment world-wide.

8.Packing Details

Packing: inside plastic bag, outside wooden case for core filling snack food puffed food making machine (Based on the customers' need adopt the wooden case or wooden pellets, etc.).

Transportation: shipping, train, express or upon clients' demands.

9.Datong Service

1. Free consultation service before, during, and after sales;

2. Free Project planning and design services upon clients' special demands;

3. Debugging and inspecting of equipment until everything is functional before leaving the factory;

4. Overseas installation and training of equipment maintenance and operating personally;

5. Provide basic production techniques and formulas;

6. 1 year complete warranty for Extruded Food Wheat Corn Snack Pellet Making Machine.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23