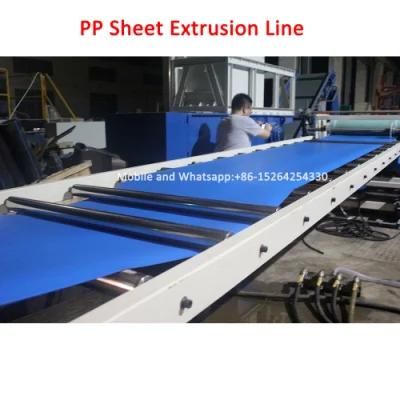

with Ce ISO Certificate PP Sheet Production Line

Xinzheng Lifa Abrasives & Abrasives Co. Ltd / 2022-07-04

=== Base Info ===

=== Description ===

1.Special designed high plasticization high efficiency screw, head finishing reduction gearboxes and high quality converter motors make high output capacity extruder;

2.Well known brand electrical components, high torque force motors, advanced energy saving design lowered energy consumption mostly;

3.High precise T-type die-head, independent oil temperature control high accuracy 3-roller calender, uniform speed and high

traction force haul-off machine with clamp force adjustable rollers make uniform thickness sheet plate production;

4.Whole line with high degree of automation, saving labour resources;

5.Advanced design concept, high quality steel material used in line, strict producing process make high quality lines and can using longer.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23