Air Bubbles Vegetable Washer Green Leaf Vegetable Lettuce Spinach Washing Machine

Wuxi Xinrun Protective Film Co., Ltd. / 2022-07-05

- After-sales Service:Video,Door to Door

- Warranty:1 Year

- Type:Washer

- Voltage:380V,50Hz

- Power:1.5KW

- Customized:Customized

=== Base Info ===

- Model NO.:TSXQ-30

- Material:304 Stainless Steel or According to Customer Requi

- Working Size:1500*520*100mm

- Ozone:with

- Air Bubble:with

- Water Spraying:High Pressure

- Cleaning:Equiped with Hoisting System for Easy Cleaning

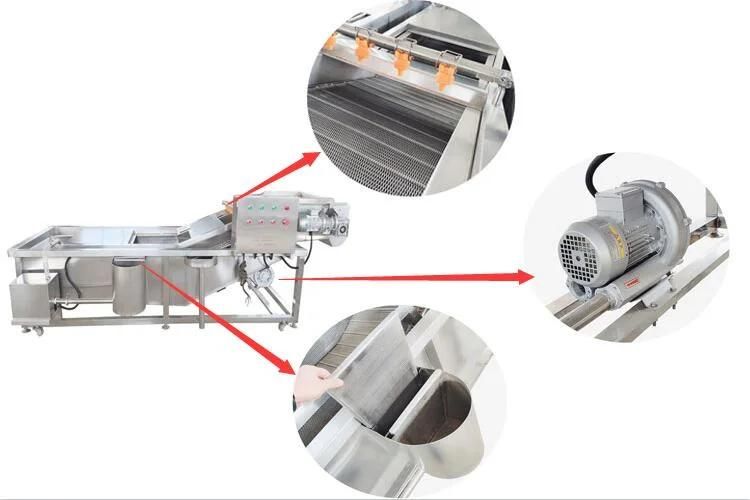

- Conveyor:Stainless Steel Mesh Belt

- Speed:Adjustable

- Transport Package:According to Customer Requirement

- Specification:3200*1350*1100mm

- Trademark:AMBITIOUS

- Origin:China

- HS Code:8438600000

- Production Capacity:200pieces,Year

=== Description ===

Basic Info.

Model NO. TSXQ-30 Material 304 Stainless Steel or According to Customer Requi Working Size 1500*520*100mm Ozone with Air Bubble with Water Spraying High Pressure Cleaning Equiped with Hoisting System for Easy Cleaning Conveyor Stainless Steel Mesh Belt Speed Adjustable Transport Package According to Customer Requirement Specification 3200*1350*1100mm Trademark AMBITIOUS Origin China HS Code 8438600000 Production Capacity 200pieces/YearProduct Description

Air Bubbles Vegetable Washer Green Leaf Vegetable Lettuce Spinach Washing Machine

1. -Machine Introduction

Fruits and vegetables bubble washer works with both a combination of high-pressure water spraying and air bubble,which can achieve the effect of cleaning and removing impurities for most leafy vegetables, some of root vegetables and fruits,such as apple,peach,pear,kiwi fruit,mango,lemon,tomato,carrot, onion,etc.

The First Stage:

Put the fruits and vegetables into the continuous bubbling spray vegetable washing machine, perform the initial cleaning, and rinse the fruits and vegetables. The washing machine is equipped with a bubble generating device to make the fruits and vegetables rolling, then can separate the sediment, hair fiber, insect eggs and residual pesticides effectively, while the fruits and vegetables are not damaged.

The Second Stage:

Fruits and vegetables are transferred to the secondary washing area with spray pipes through the mesh belt for secondary cleaning. During the conveying process, the products are cleaned and rinsed once again. On the other hand, achieve the purpose of adding water into the tank. Floating matter can overflow from the overflow tank, and the sediment is discharged from the drainage hole on the bottom of the tank.

The Third Stage:

After the washing is completed, the fruits and vegetables are transported by the mesh belt conveyor to the next process.

Features:

- Completely built of SS304,safe for foodstuffs.

- Electric drive.

- 200 to 300 kg/hour.

- Air bubble washing.

- High pressue spary water washing.

- Ozone sterilization.

2. -Technical Data

Bubble Washing Machine:

| 1 | Model | TSXQ-30 |

| 2 | Processing capacity | 200-300kg/hr |

| 3 | Overall Dimensions | 3200*1350*1100mm |

| 4 | Electric source | 380V/50HZ |

| 5 | Power | 1.5KW |

| 6 | Hoister | Without |

| 7 | Working Type | Continuous |

3. -Details

4. -Suitable For Products

For washing leafy vegetables, part of root vegetables and fruits, seafood, can be used as a stand-alone machine, or assembled

on complete line for continuous process.

5. -Using Scene

6. -Applications

The equipment is suitable for canteens, central kitchens, fast food restaurants, meat food factories, snack food factories.

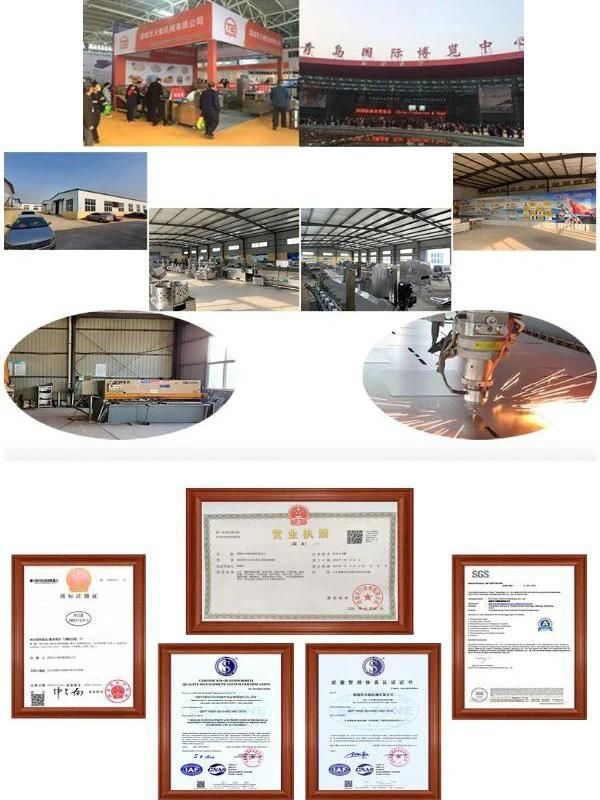

7. -Company Profile

Zhucheng Tianshun Machinery Co., Ltd. is a modern food machinery manufacturer integrating R&D, manufacturing, marketing and after-sales.

Main products including food processing machinery, including:

Vegetable/fruits washing machines;

Vegetable peeling machines;

Frying machines;

Coating&blender equipment;

Flavouring machines;

Blancher;

Hot/cool air drying machines;

Vacuum packaging machines;

Vegetable/fruits cutter;

Pasteurizer equipment;

Vacuum fryer;

Freeze dryer;

Liquid nitrogen freezer;

Complete production lines,potato chips/french fries production line,plantain chips line,vegetable/fruits processing line,etc.

They are mainly used for processing vegetable, fruits, pickled foods, chicken, meat, seafood, and so on. All of the products could be customized produce in individual or a complete line.

8. -Our Clients

9. -Packing And Shipment

10. -FAQ

Q1.Could we visit your factory to check the machine carefully and closely?

A:Welcome to our facotry,will provide machines testing service,face-face discussing,turnkey project design solution.

Q2.How long is your machine's guarantee time?

A:1 year without normal wear parts,machine itself life guaranteed.

Q3.If we have very special request for the complete production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q4.If we show you our layout of factory,can you help to design the whole process line?

A:Layout design service provided after received customer's factory layout size.

Q5.If we have samples of new products,can you help to analysis and design the machine?

A:Yes,our technical department can help to analysis,design and test the new products based on the specific requirements you provided.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23