Biscuit Making Machine /Maker Biscuit Production Equipment Soft and Hard Biscuit ...

Shandong Longxing Plastic Film Technology Co., Ltd. / 2022-07-05

- After-sales Service:Povided

- Warranty:1 Year

- Certification:CE, ISO9001

- Power Source:Electric

- Automatic Grade:Automatic

- Application:Soft and Hard Biscuit

=== Base Info ===

- Model NO.:DH 225 DH280 DH400 DH600 DH800

- Customized:Customized

- Equipment Name:Biscuit Production Line

- Frequency Converter:Delta Brand

- Machine Material:Stainless Steel

- Product Formula:Seller Provide Formula

- Warranty Period:12 Months

- Applicable Industry:Food Processing Machine

- After Sales Service:Seller Send Engineer for Installation and Training

- Spare Parts:Provide by Seller

- Delivery:Arrange by Seller

- Certificate:CE, ISO

- Automatic:Fully Automatic

- Key Words:High Capacity Good Price Biscuit Production Line

- Place of Origin:Jinan, China

- Voltage:Customer Settings

- Company Type:Real Factory

- Transport Package:Film&Wooden Box Packing

- Specification:2.5*1.2*1.5m

- Trademark:Donghe

- Origin:Jinan, China

- HS Code:8438800000

- Production Capacity:50-60kg,H 100kg,H 200kg,H 500kg,H 1000kg,H

=== Description ===

Basic Info.

Model NO. DH 225 DH280 DH400 DH600 DH800 Customized Customized Equipment Name Biscuit Production Line Frequency Converter Delta Brand Machine Material Stainless Steel Product Formula Seller Provide Formula Warranty Period 12 Months Applicable Industry Food Processing Machine After Sales Service Seller Send Engineer for Installation and Training Spare Parts Provide by Seller Delivery Arrange by Seller Certificate CE, ISO Automatic Fully Automatic Key Words High Capacity Good Price Biscuit Production Line Place of Origin Jinan, China Voltage Customer Settings Company Type Real Factory Transport Package Film&Wooden Box Packing Specification 2.5*1.2*1.5m Trademark Donghe Origin Jinan, China HS Code 8438800000 Production Capacity 50-60kg/H 100kg/H 200kg/H 500kg/H 1000kg/HProduct Description

Biscuit Making Machine /Maker Biscuit Production Equipment Soft and Hard Biscuit Processing LineProduct Description Of Biscuit Making Machine

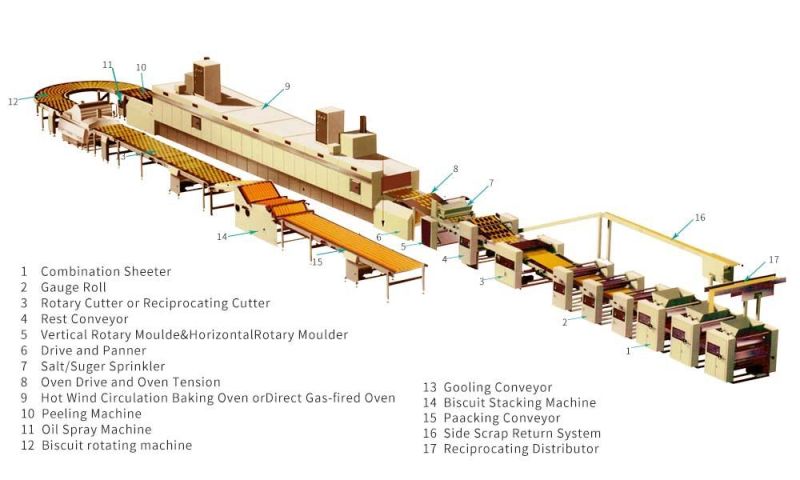

Biscuit Making Machinery is composed of biscuit forming machine, tunnel-type hot air circulation electric oven, fuel injection machine, turning machine, cooling line, biscuit finishing machine, biscuit sandwiching machine, packaging table, etc. Biscuit Making Machine adopts compact structure, high degree of automation, from feeding, three-stage pressing, forming, sugar screening, conveying, waste, and recycling. All mechanical integration such as baking, fuel injection and cooling are completed automatically. Hot sale biscuit production line is novel in design, compact in structure, and highly automated. From feeding to calendering, forming, waste recycling, drying, oil spraying, and cooling, it can be completed in one go.

Output and Parameters of Biscuit Making Machine

| Model | DH225 | DH280 | DH400 | DH600 | DH800 |

| Installed Capacity | 28.5KW | 55KW | 110KW | 220kw (gas type 25kw) | customize |

| Heating Source | Electrical | Electrical | Electrical, Gas | Electrical,Gas | Electrical, Gas |

| Baking temperature | 200-300ºC | 200-300ºC | 200-300ºC | 200-300ºC | 200-300ºC |

| Production capacity | 50~60Kg/h | 100kg/h | 150-200Kg/h | 400-500kg/h | 600-900kg/h |

| Production line length | 21000mm | 30000mm | 43000mm | 60000mm | customize |

Features And Functions Of Biscuit Making Machine

(1).According to the needs of users, we can produce wafers of different sizes and different shades of patterns

(2).Made various shapes of wafers according to the needs of users, such as: spherical, square, bar, etc.

(3).The wafer can be transported to the chocolate coating machine through the cake divider to make chocolate wafers.

(4).Fully automatic production process.

The Composition Of Hot Sale Biscuit Making Machinery

Biscuit Forming Machine-Tunnel Hot Air Circulation Electric Oven-Oil Spraying Machine-Turning Machine-Cooling Line-Biscuit Finishing Machine-Biscuit Sandwiching Machine-Packaging Machine

The Technological Process Of Hot Sale Biscuit Making Machinery

Flour, Auxiliary Materials-Dough Preparation-Tabletting-Rolling Forming-Baking-Oil Spraying Machine-Cooling-Finished Product

Details Of Biscuit Making Equipment

Finished Biscuit Pictures

cream biscuit, layer biscuit, soda cracker, calcium biscuit, multi-vitamin biscuit, vegetable biscuit, etc.

Company Introduction

We are a reliable factory located in the beautiful spring city of Jinan, China.

We have a complete management system ISO9001.

We are the largest food processing machinery manufacturer in Jinan, the main products: pet food machinery, snack machinery, fruit and vegetable cleaning and processing machinery, biscuit machinery, instant noodle machinery, pasta machinery, etc. - food processing machinery manufacturers!

More than 20 engineers have more than 8 years of work experience and have traveled to more than 50 countries and regions.

Provide 24-hour telephone mail service to provide you with timely and feasible solutions and better after-sales service.

Customer-Factory

Delivery

Delivery Packing

PackingWe can supply you the seasons bag packaging machinery. To loading spices powder and oil.

Packaging:

Inside: plastic bag.

Outside: wooden case (adopt the wooden case or wooden pellets depended on customers' requirement).

Shipping

One 20ft container or 40ft container

Our company has already exported countries:

Asia {Thailand, Indonesia, East Timor, South Korea, India, Bangladesh, Iran, Saudi Arabic, Turkey, Iraq, Israel, Kazakhstan, Tajikistan, Uzbekistan, Turkmenistan}

Africa { Nigeria, Benin, Algeria, Egypt, Ethiopia, Ghana, Namibia, Uganda, Zimbabwe}

Europe { Russia, Bulgaria, Ukraine }

North & South America { Canada, Brazil, Bolivia }Ocea

Glories

Glories

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23