WPC Foaming Sheet Extruding Machine/Plastic Board Extruding Process

Kunshan Canuri Precision Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJSZ80/156 Customized Customized Condition New Plastic Foaming Board Making Machine PVC Foam Board Machine Transport Package on Demand Specification 1220x2440mm Trademark Sanyi Origin China HS Code 847780000 Production Capacity 350-400kg/HProduct Description

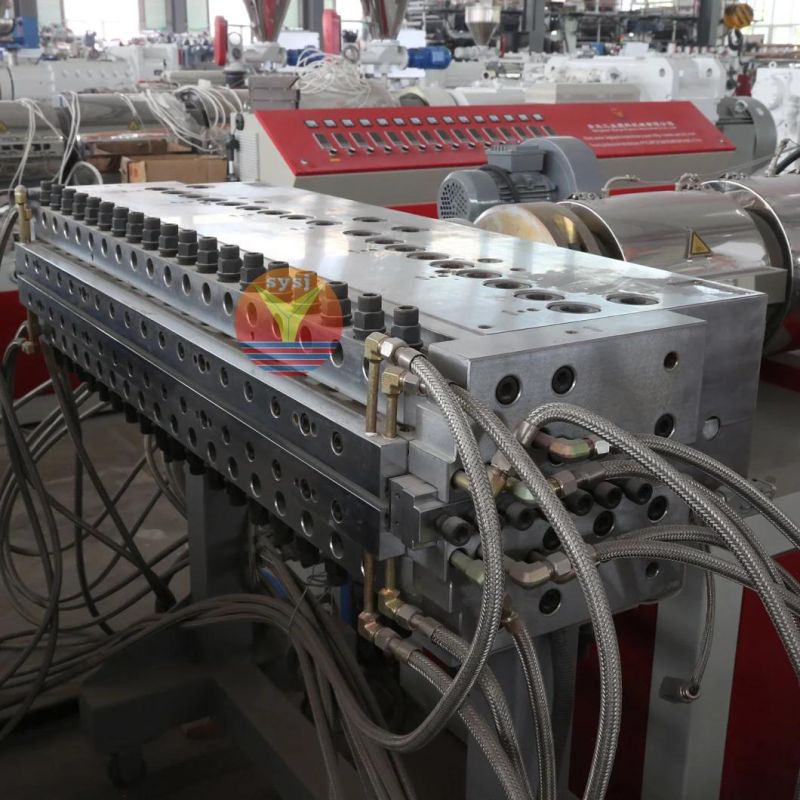

WPC Foamed Board Extrusion Machine/------------------------plastic boarding making machine

Wood-plastic extrusion line using specially designed screw barrel, mold and extruding machine production of wood-plastic products processing production process. Product include: Wood -plastic step plate equipment; Wood-step-shaped equipment; Wood-step decoration materials and equipment; Wood-plastic two-step plate equipment; Wood two-shep-shaped equipment; Wood pelletizing equipment.

Wood products may be stand-alone direct extrusion extruder can also be extrusion granulation after the two-shep method, with energy-saving, space-saving, high output, extrusion stability, and plasticizing effect is good. Optimized design smaller screw to shear force, thus easy to cut the wood fiber material can stay in the machine evenly. Screw barrel are taking pairs of metal processing, wear corrosion, significantly longer service life

Usage; This production line can product profiles of plastic-wood, Primary use in floor, tray, packaging boxboard, outdoors decorative materials, etc.

The only professional manufacturer in pvc foam board machine in China

1.SJSZ 80/156 Conical twin Screw Extruder

1.SJSZ 80/156 Conical twin Screw ExtruderABB Frequency Converter, SIEMENS Contactor, OMRON Japan, Motor Power:75KW

2.Calibration unit

Calibration Plate:1500mm×500mm 4couples

3. Cooling Tank and Bracket

Length:6000mm

Trimming Knife:3 sets

4. Haul-off Unit

8 Couples

Cylinder Clamping and Loosening

5. Cutting unit

6. Stacker

7. Mould (T-Die )

Advantages of PVC foam board

First of all:

this is a completely waterproof material, because it is plastic, it is widely used in the place of the outside balcony, Plank Road, a swimming pool, lake, beach, ship deck and so on.

Secondly, this is a completely anti-termite, anti-moth-eaten material, because it does not contain fibrin.

Third, this is a material with a good performance of flame retardant. We have done experiments. This excellent fire retardant property of foam boards foam is much better then wood and wood-plastic materials.

Fourth, it is one that does not decay, is radiation-free and non-toxic and in line with national testing standards. It is maintenance-free, and the maintenance of pollution can be avoided.

Fifth, the bending resistance of this material and a surface hardness are higher than that of wood, wood materials. The grip nails is stronger than the wood-plastic which is flat with wood.

Sixth, price levels of this material in the current market has the promotion conditions, it is definitely cheap and fine

Company Information & Professional Service:

Qingdao Sanyi Plastic Machinery Co., Ltd., located in Qingdao, China, is a professional manufacturer of PVC Celuka Foam Board production line. With more than 10 years' research and development, Qingdao Sanyi now are proud of these production lines: PVC/WPC (Wood Plastic Composit) crust foam board extrusion line, PVC crust foam board extrusion line, PVC wood plastic foam board extrusion line, PVC building board extrusion line and PVC free foam

board extrusion line.

Pre-sale service:

To provide information and market research,to provide consultation,to provide many kinds of conveniences and market service,etc. Products: PVC Foam Board Machine...

The main purpose of pre-sales service is to help customers make the project planning and system requirements analysis. Make our products maximum to meet clients' requirements. Also play the greatest overall economic benefits of customers' investment.

After-sale service:

To install products and test products freely for customers.

To provide the formulas and technologies of relevant products and the information of chemical materials manufactories.

To direct technology aspect of relevant use according to customers' requirements

To provide technical training for clients' employees.

To be responsible for maintenance service, door-to-door service under the necessary circumstance.

Technology support:

To provide installation and test for the machine.

To provide formulas and technology of relevant products.

To provide information of chemical material manufactories.

To provide technical training for clients' employees.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23