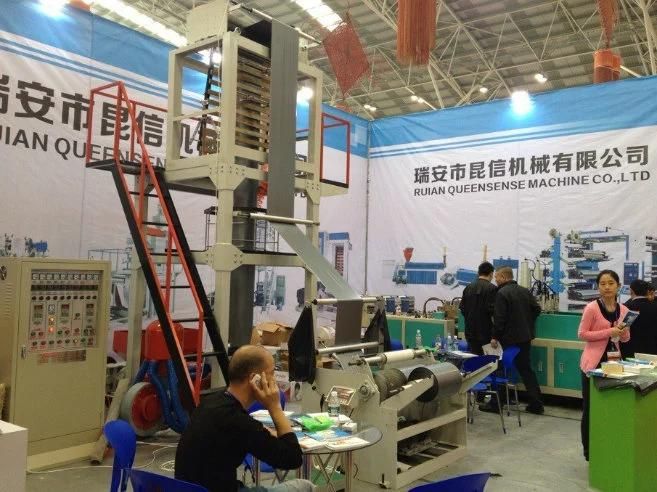

800-1400mm Size LDPE&HDPE Film Blowing Machine

Shanghai Robustworks Hardware Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

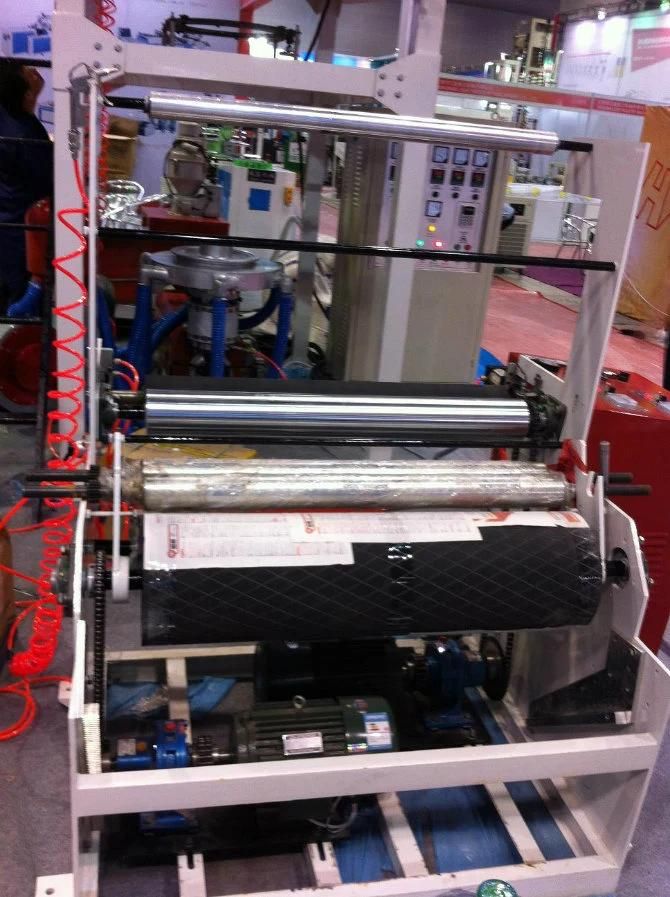

Model NO. QS-A65 Raw Material HDPE/LDPE/LLDPE Maximum Folding Width of Film 1400mm Screw Diameter 60mm Automation Non-Automatic Computerized Computerized Machine Weight 3t Certification CE Film Wdith 800-1400mm Motor 37kw Gear Box 200cm Screw 65mm Die Head 280mm Rotary Die Head Rewinder Double Rewinder Capacity 90kg/H Material HDPE/LDPE/LLDPE Transport Package Wooden Box Specification CE Trademark QUEENSENSE Origin China HS Code 84773000 Production Capacity 35/50/65/80kg/HProduct Description

Use:

Its extruder, cylinder and screw rods are made of quality alloy steel that have been nitrized and processed in a precision way. Hence it is sound in hardness, durable in corrosion resistance. The specially-designed screw is of sound quality in plasticizing, which helps increase the production capacity. It is applied to blowing the plastic films like low density polytene (LDPE), high density polytene(HDPE) and linear low density polytene (LLDPE). It is widely applied to producing the packing bags for foodstuff, clothing, rubbish bag and vest ones.

Optional equipment:

1). Auto load

2). Air compressor

3). Special die

4). Die rotary device

5). Bouble sides winder

6). Up and down

Model | A50 | A55 | A65 | A65-1 |

| Diameter of screw | φ50 | φ55 | φ65 | φ65 |

| Rcduced diameter of film(mm) | 100-600 | 200-800 | 300-1000 | 400-1200 |

| Single-face Thickness of film(mm) | 0.01-0.10 | 0.01-0.10 | 0.01-0.10 | 0.01-0.10 |

Max.Extrusion(Kg/h) | 35 | 50 | 65 | 80 |

| L/D | 28:1 | 28:1 | 28:1 | 28:1 |

| Power of main moto(kw) | 11 | 15 | 18.5 | 22 |

| Power of Tracion main moto(kw) | 0.75 | 1.1 | 1.5 | 1.5 |

| Heating Power(kw) | 15 | 18 | 23 | 27 |

Outline diameter(L x W x H) (mm) | 4800 x 1900 x 4100 | 5500 x 2100 x 4700 | 6500 x 2300 x 4900 | 6500 x 2500 x 5600 |

| Weight(T) | 1.5T | 2T | 2.3T | 2.6T |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23