PVC Hollow Roofing Extrusion / Corrugated Sheets 2-in-1 Machine by Changing Mold

Fujian Quanzhou Huazuan Diamond Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Customized Customized Condition New Transport Package Plastic Film Package and Loaded Into The Container Specification 28m*5m*5m Trademark Acemien Origin Jiangsu Province HS Code 84772090 Production Capacity 1000 Sets/YearProduct Description

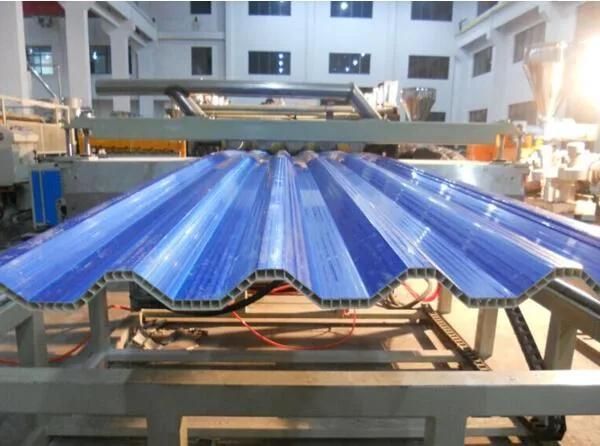

PVC Hollow Roofing extrusion / Corrugated Sheets 2-in-1 Machine By Changing MoldThe PVC Hollow Roofing extrusion / Corrugated Sheets 2-in-1 Machine By Changing Mol can produce the corrugated roofing sheet, and the roofing sheet 1.5-4.0mm, Output:350-400kg/h(Depending on CaCO3 proportion).

The raw material is : PVC powder, CaCO3, CPE, PE-WAX, Stearic acid , Compound stabilizer ,ACR, paraffin,ASA granule.

The PVC Hollow Roofing extrusion / Corrugated Sheets 2-in-1 Machine By Changing Mol inlucing below parts:

Screw loader for SJZ 80/156 extruder

SJZ 80/156 conical twin-screw extruder(PVC)

Vacuum loader and drying hopper

SJ50/30 single screw extruder(ASA)

Extrusion mould and distributor

Forming table

Haul off unit, 6 stations of haul off rollers.

Cutter, the cuttig method is pneumatic saw cutting, the tracking cutting method.

Stacker, the normal receiving table is 3 meters/2 sets.

This is the haul off unit of thePVC Hollow Roofing extrusion / Corrugated Sheets 2-in-1 Machine By Changing Mold.

There are 6 teams of stations of the rollers which is with the fuction of the hauling off.

This is the cutting system of the PVC Hollow Roofing extrusion / Corrugated Sheets 2-in-1 Machine By Changing Mold.

This is the receiving table of thePVC / ASA Twin Wall Hollow Corrugated Sheet Making Machine .

If you need this Two-layers Hollow Corrugated PVC Roof Tile Production Line plasic extrusion machine or you are interested in this Two-layers Hollow Corrugated PVC Roof Tile Production Line plasic extrusion machine.

please feel free contact me please.

My name is Karry

Tel :+8618205059535

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23