Corn Flakes Cereal Snacks Puff Making Machinery

Qingdao Albar Import And Export Trade Co., Ltd. / 2022-07-05

- Certification:CE, ISO9001, SGS

- Power Source:Electric

- Process:Puff Snack

- Automatic Grade:Automatic

- Application:Popcorn, Chips, Puff Snack

- Customized:Customized

=== Base Info ===

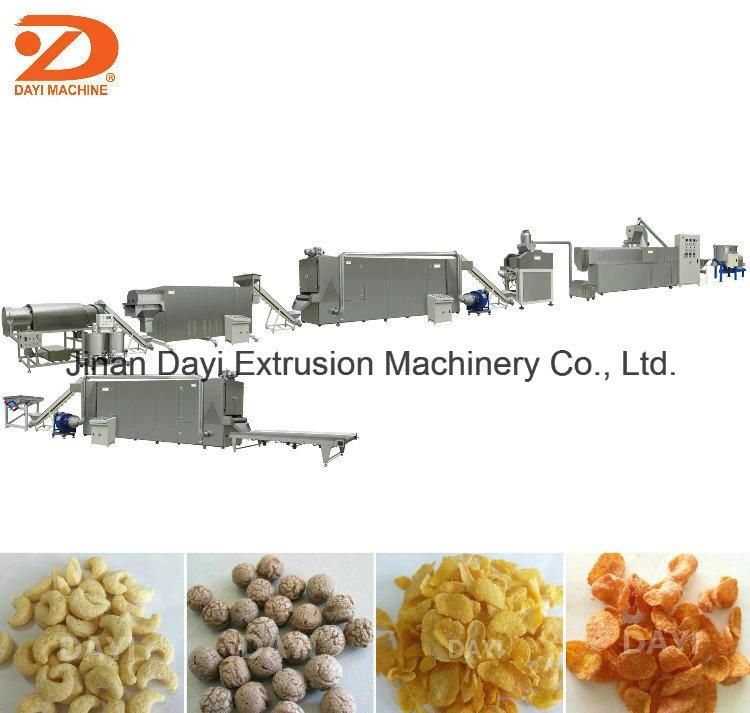

- Machinery:Fully Automatic Corn Flakes Machine

- Machine:Snack Food Machine

- Transport Package:Wooden Case

- Specification:CE, ISO, SGS

- Trademark:Jinan Dayi

- Origin:Jinan

- HS Code:84198100

- Production Capacity:3000PCS,Year

=== Description ===

Basic Info.

Machinery Fully Automatic Corn Flakes Machine Machine Snack Food Machine Transport Package Wooden Case Specification CE, ISO, SGS Trademark Jinan Dayi Origin Jinan HS Code 84198100 Production Capacity 3000PCS/YearProduct Description

Corn Flakes Cereal Snacks Food Frying Chips Making Machine

Corn Flakes Processing LineBrief decription:

This corn flakes processing line can not only produce the corn flakes but also breakfast cereal products by adjusting some assistant machines.

The main raw material is corn powder in 60-80 mesh, and other grain powder or some nutritional ingedients, like vitamin. The raw materials will be cooked well in the extruder by twin screw rotating under high temperature and pressure. After the high temperature roaster, the flakes will be bublled and smelt well.

The coating line can make the syrup or honey on the flakes surface.

This corn flakes processing line is characteristics of simple opeation, reasonable structure, low consumption, and high efficiency, which make it the best choice for medium factory.

1. Double-screw Extruder

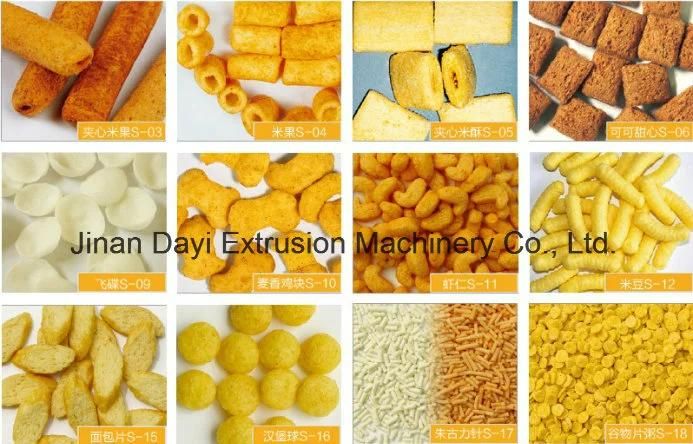

2. Various Shape Snacks by changing the mould

3. Capacity: 100-150kg/h,200-250kg/h,300-500kg/h optional

The Puffed Snack Extruder can produce snacks with different textures and tastes.

Raw materials:wheat, rice, corn and other common grains.

Flour Mixer → Screw Elevator → Double-screw Extruder → Air Convveyor → Flaking Machine → Elevator → Dryer → Elevator → Roaster → Elevator → Coating Line → Vibrating Spreader → Elevator → Dryer → Cooling Conveyor

Snacks produced:

JINAN DAYI EXTRUSION MACHINERY CO.,LTD

Established in 1996, Jinan Dayi Extrusion Machinery Co., Ltd has been the professional manufacturer and the model company for advanced and high efficient extrusion food machinery in this field. DAYI Company congregates an expert team with twenty-year experiences in this extrusion machine industry, not only working hard to constantly researching extrusion technology, but also exploring food processes in order to benefit our clients producing creative food.

After years of research and development, our single and double screw extrusion technique has been widely applied to produce the following products: puffed snacks, core-filling snacks, breakfast cereal / corn flakes, 2d/3d pellet, textured soya protein/fibre protein/vegetarian meat, doritos/ tortilla chips, cheetos/niknak/kurkure, ball/butterfly popcorn, fried flour food, bread crumb, nutritional rice/ artificial rice, nutritional powder/baby food powder, and pet food, etc. More than twenty production lines with different functions and capacities can be chosen. And we can also provide customized service for special requirements.

"Create Greatest Value for Clients" is our consistent concept and the base of long-term cooperation with clients. In these years, our machines have large domestic market share. Some food companies famous now grew up together with us, and many influential large food companies and groups have chosen us and set up long-term cooperation, such as, China Oishi Food Company (headquarters in Philippines), Panpan Food (Fuyuan Group), Hsufuchi Group, Fujian Qinqin Incorporated, Wangwang Group, Master Kong Company, Tianjin Longkang Company, Jiangsu VV Group, Fuwa Group, Gloden Monkey Food Company, Hebei Dingda Food Group, Hangzhou Daen company, etc.

Meanwhile, our machines have been exported to about fifty countries and regions for these twenty years, such as Malaysia, Indonesia, Philippines, Vietnam, Cambodia, Thailand, Japan, South Korea, India, Pakistan, Russia, Kazakhstan, Uzbekistan, Turkmenistan, Jordan, Iran, Israel, UAE, Egypt, South Africa, Algeria, Congo, Netherlands, Poland, Macedonia, Czech, Brazil, Argentina, Mexico, Australia, etc. Dayi machines have gained high reputation for the high quality, low cost, and low consumption. And we will continuously provide the best machines and best services.

If you have any need for our snacks machines, please contact us when feel free.

Also welcome you come to have a visit of us.

Our Services

(1)Provide you the professional advice about the

market,equipment,process,materials,packing,etc.

(2)Assist you to choose equipment,design process flow,and perfect

workshop layout.If needed,we can supply service in your factory.

(3)Material change according to your product,and perform the

production at site.

(4)Specially design and manufacture machine,practice test,and

provide relevant training as customer required.

(5)Provide reasonable packing and transportation plan,send

technician to install and debug machine and train your workers.

(6)One year guaranty time,preferentially supply spare parts.

(7)Design and process similar type spare parts of import

equipment.

Value-added Service

(1)Constant improvement on machinery,mould and food technics

increases the competition ability and creates furthest value for

you.

(2)Regular training for above-mentioned improvements helps you

produce superior and competitive products with high efficiency.

FAQ

Generally questions you will meet during you choose the suitable machine:

1.Voltage

DAYI:Adjustable to your local voltage,such as 3ph 415v 50hz,3ph 380v 60hz,3ph 440v 60hz,3ph 220v,60hz.

2.Material

DAYI:Stainless steel for the parts which directly connect with the food.

3.Brand of Motor?eletronic components?

DAYI:ABB,SIEMENS or Chinese Top Brand,it depends on your requirements.

4.Fuel for dryer and fryer

DAYI:Gas,diesel,eletricity as fuel

5.Customer Visiting

DAYI:We can arrange to pick up customer when visiting

6.Gurantee time?

DAYI:Normally our gurantee time is one year except easy broken parts.

7.Comissioning

DAYI: We can send technician team to your country

Contact Person: Ms.Emma

Tel: +86-531-88600886

Mobile/Wtsapp/Skype:+86-13573772959

Add: Shandong Yuanyi Industrial Park,No.36,Wuyingshan North Road,Jinan,China 250032

Http://dayimachine.en.made-in-china.com

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23