Acme 100tpd High Quanlity Stainless Steel Parboiling Rice Milling Plant

Guangzhou Chengxing Packaging Material Co., Ltd. / 2022-07-04

- Application:Flour, All, Rice flour, Rice Milling

- Voltage:380V

=== Base Info ===

- Model NO.:AMP-100

- Appearance:Vertical

- Press Materials:Rice

- Press Series:Continuous

- Condition:New

- Customized:Customized

- Brand Name:Acme

- Model:AMP-100tpd

- Power(W):500kw

- Weight:260t

- Dimension(L*W*H):60X18X20m

- Certification:TUV, ISO, BV, SGS, Ce

- Fuel:Rice Husk

- Boiler:Gas, Coal, Diesel, Rice Husk

- Material:Stainless Steel

- Range of Application:Paddy Rice

- Service:on-Site Installation and Commissioning by Engineer

- Dryer:Fluidized Bed and Stainless Steel Low Temperature

- Function:Cooking, Soaking and Drying The Parboiled Rice

- Capacity:100tons Per Day

- Hscode:8437800000

- Transport Package:Wooden Case

- Specification:AMP-100

- Trademark:ACME

- Origin:China

- HS Code:84378000

- Production Capacity:30 Sets,Year

=== Description ===

Basic Info.

Model NO. AMP-100 Appearance Vertical Press Materials Rice Press Series Continuous Condition New Customized Customized Brand Name Acme Model AMP-100tpd Power(W) 500kw Weight 260t Dimension(L*W*H) 60X18X20m Certification TUV, ISO, BV, SGS, Ce Fuel Rice Husk Boiler Gas, Coal, Diesel, Rice Husk Material Stainless Steel Range of Application Paddy Rice Service on-Site Installation and Commissioning by Engineer Dryer Fluidized Bed and Stainless Steel Low Temperature Function Cooking, Soaking and Drying The Parboiled Rice Capacity 100tons Per Day Hscode 8437800000 Transport Package Wooden Case Specification AMP-100 Trademark ACME Origin China HS Code 84378000 Production Capacity 30 Sets/YearProduct Description

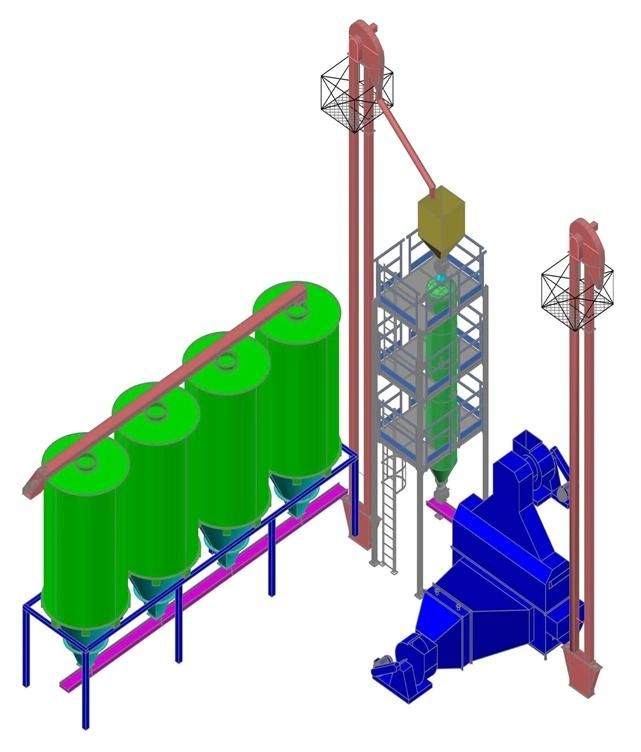

AUTO modern stainless steel Parboiled Rice Milling Plant

We can provide you 10-1000tons per day auto modern parboild rice milling plant/

Parboiled rice mill machine/ parboiled rice mill processing line.

Specifications:

1 / HEAT EXCHANGER LOW PRESSUR

2 / SOAKING TANK - RECYCLING THE VAPOUR SO CREATED IN THE SOAKING TANK WHILE BOILING TO REDUCE THE TIMING IN THE BOILING IN ORDER TO INCREASE THE PRODUCTION

3 / DRIER - SPECIAL DRIER WITH MINIMUM TIME IN THE PROCESS AS THE REMOVAL OF MOISTURE FROM THE CHAMBER IS PROVIDED.

24 TONS BATCH IS THE BEST OPTION OF THE DRIER TO GIVE THE PROPER TREATMENT TO THE PADDY WITH LOW PERCENTAGE OF THE BROKEN RICE.

IF THE CAPACITY IS 96 TONS BATCH MEANS 24 TONS BATCH X 4 DRIERS ARE REQUIRED TO BE INSTALLED

Product Description

1/5 of world paddy are made into pre-boiled rice. Pre-Boiled rice has fully absorbed the nutrition of rice and has good flavor, also during the course of boiling it killed the pest and make rice easy to store.

We can supply parboiled rice milling plant for you demand.

Parboiled rice use steamed rice as raw material, after cleaning, soak, cooking, dry and cooling water after heattreatment,

Then press the conventional rice processing method for life Produced and the product.

Compared with the same level ordinary rice, it has the following advantages:

High nutritional value

Easy to be human digestion and absorption

Grain structure is tight and ratio of winnowed paddy is high

Rice bran haracteristicf high

Storage and easy keeping

Product process details description

1) Cleaning

In this stage we remove the dust from the paddy,

If the paddy has dust when it is soaking it will pollute the water and influence the nutrition of rice.

2) Soaking.

The aim of soaking is make paddy absorb enough water, creat conditions for starch pasting.

During the course of starch pasting paddy must absorb above 30% water,

Or it will not be able to fully steam the paddy in next step and thus to influence the quality of rice.

3)Steaming.

After soaking the inside of endosperm has got many water, now its time to steam the paddy to realize starch pasting.

Steaming can change the physical structure of rice and keep the nutrition, to increase the production ratio and make rice easy to store.

4) drying and cooling.

The aim of drying is to make moisutre reduced from around 35% to around 14%.

To reduce moisture can greatly increase the production ratio and make rice easy to store and transport.

5) Husking.

After soaking and steaming it will be very easy to husk the paddy and save energy.

6) Milling.

The pearling of pre-boiled rice cost much more time than normal paddy.

The reason is that after soaking the rice is easy to become smectic.

In order to avoid this problem we use blowing rice miller, and increase the rotating speed of rice miller,

The rice bran transmission adopt neaumatic type to reduce the friction.

7) polishing and grading.

Grading machine is used to separate different quality rice and separate broken rice from the good ones.

Good rice come through the polishing machine, it will make the milling rice become more beautiful color and more smooth, thus to increase the quality of rice.

8) Color sorting.

The rice we get from above step still has some bad rice, broken rice or some other grains or stone.

So here we use color sorting machine to select the bad rice and other grains.

Color sorting machine is an important machine to ensure we can get high quality rice.

9) Packing.

The finish rice now is ready dear all!

Let's use our automatic weighing and packing machine to make them into 5kg 10kg or 50kg bags.

This machine is electric type, you can set it like a small computer, then it will start working according to your request.

From this machine you will get bag type rice and you can supply your rice to all your customer!

Rice Mill Production Line/ Rice Milling Machine process:

| Pre Cleaning | Clean out all impurities and unqualified grains from raw paddy |

| De-stoning | Separate stones, clods from rice |

| Parboiling (Alternative) | Improve the nutritious quality and milling recovery percent during husking, polishing, whitening |

| Husking | Remove husk from rice |

| Husk Separation | Separate husk from brown rice/ unhulled rice |

| Rich Separation | Separate the unhusked paddy from brown rice |

| Whitening | Remove all or part of the bran layer and germ from brown rice |

| Polishing | Improve appearance of milled rice by removing bran and by polishing kernel |

| Color Sorting (Alternative) | Remove foreign matter such as mould, broken rice from milled rice |

| Milling | Mill the pure rice |

The working site of Rice Mill Production Line/ Rice Milling Machine

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23