PVC WPC Foaming Board Extrusion Line Door Panel Foaming Board Machine furniture Board ...

Jiangsu YiCheng Fluid Equipment Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

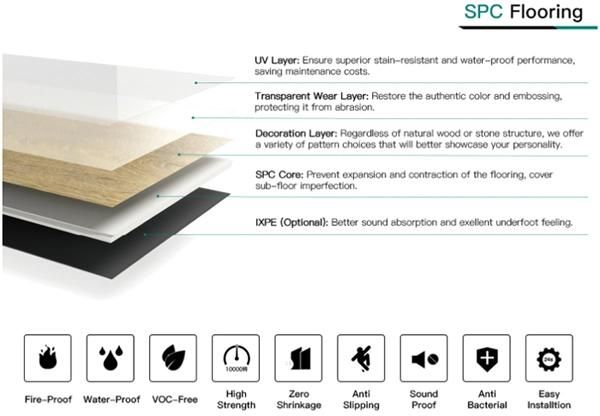

1. Waterproof and moisture-proof. The problem that wooden products are easy to rot, expand and deform after absorbing water in wet and multi-water environment has been solved fundamentally. It can be used in environments where traditional wooden products can not be applied.

2. Colorful, with many colors to choose from. It not only has natural wood texture and wood texture, but also can customize the color according to its own personality.

3 High environmental protection, pollution-free, recyclable. The product does not contain benzol and formaldehyde. It is an environmental protection product. It can be recycled, which greatly saves the use of wood, suits the national policy of sustainable development and benefits the society.

4. High fire resistance. Effective flame retardant, fire protection level up to B1, self-extinguishing in case of fire, no toxic gas produced

5. Simple installation, convenient construction, no need of complicated construction technology, saving installation time and cost

6. No cracking, no expansion, no deformation, no need of maintenance , easy to clean, save the cost of later conservation.

All Key parts: screw&barrel,melt pump, screen changer, T-die, roller and downstream equipment are made by Jwell factory!

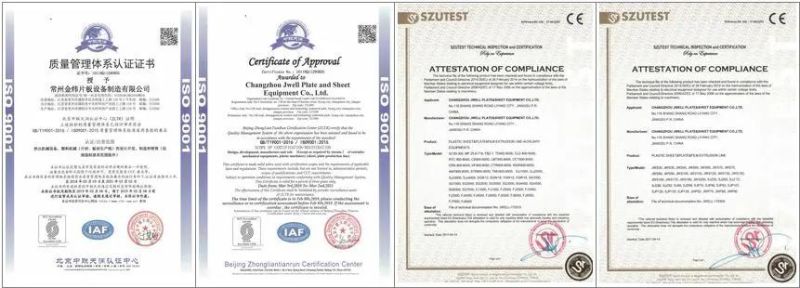

Certification

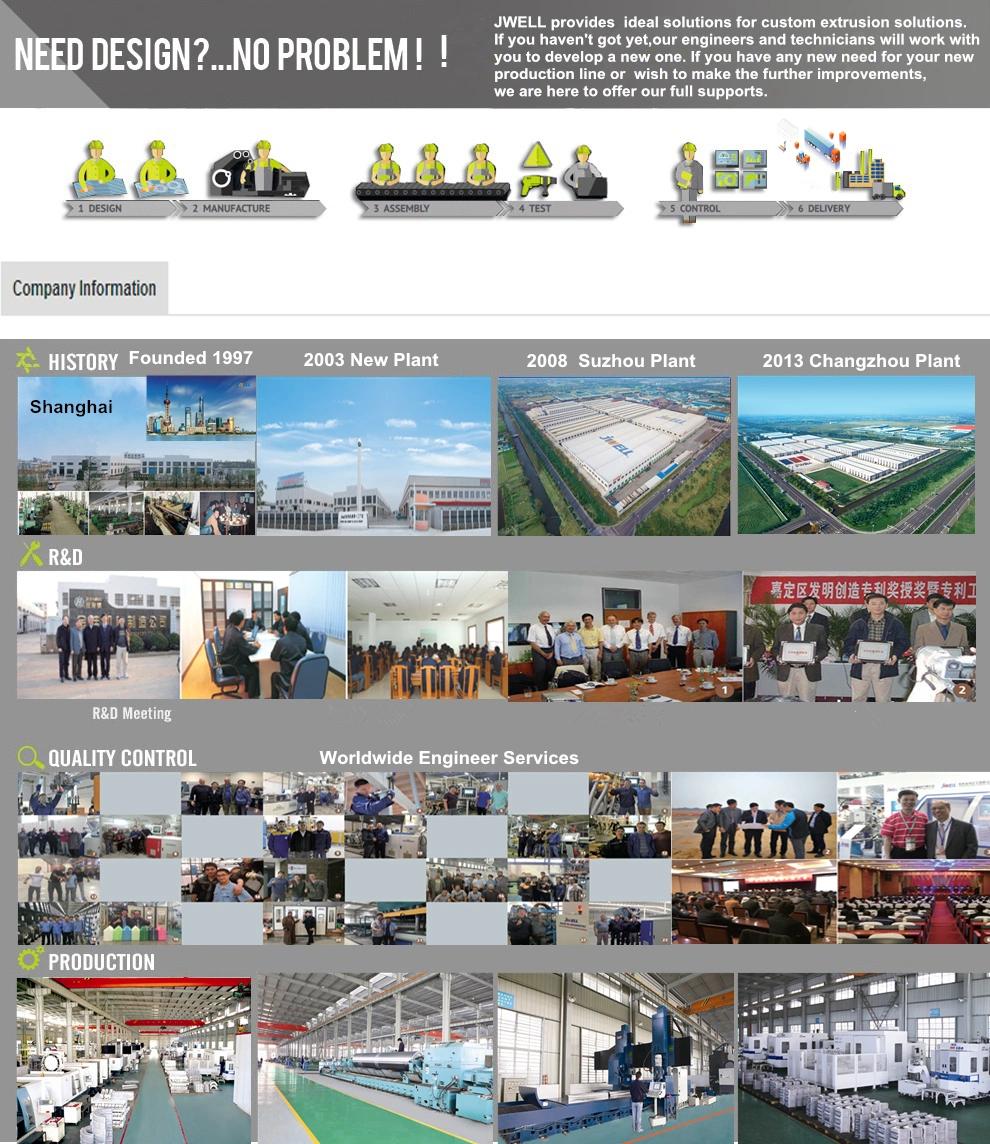

Customized Solutions

Company Information

As the vice unit of CPMIA, Shanghai Jwell Machinery Co., Ltd is the biggest manufacturer of plastic extrusion

machinery and chemical fiber spinning equipment in China, its head office is located in thewestern district of

Shanghai. There are 5 production bases, which were located in the western districtof Shanghai, Zhoushan of

Zhejiang Province, Suzhou of Jiangsu and Changzhou of Jiangsu , Dongguan of Guangdong , totally covering

700,000 square meters. It has more than 2600 staffs, about 400 technicians and managing staffs.

Main products: various plastic pipes extrusion lines including large diameter PE/PVC double wall corrugated

pipe extrusion line, large diameter PE/PVC solid wall pipe extrusion line, PP-R/PEX/PE-RT cool/hot water pipe

extrusion line, PA/PE/PVC single wall corrugated pipe extrusion line; various plastic profile extrusion lines;

various plastic plate & sheet extrusion lines; chemical fiber spinning; microcomputer controlled automatic blow

molding machines; plastic auxiliary recycling lines; various single & twin screw and barrel extruders;

T die; screen exchangers; Rollers and Robots.

Why us

Pioneering Efforts, Unity and Struggle

Seeking for innovative and practical technology, We grow rapidly with the market trend. Every person is a product

person in creating better customer experience. Trust is the corner stone of our corporate. As we truly believe the

staffs are the most precious wealth, if we take care of our employees, so as each person would take care of the

customers. "Be Honest" is the core idea for us to build an everlasting enterprise.

Consistent quality, Brands Building.

We have kept an eye on the quality during all procedures since the birth or our enterprise. Consistent quality would

be the only virtue which we highly uphold. Every product marking JWELL represents safety, stability, reliability.

Cutting edge technology, Added value products

We have professional designing engineer who recognize the market need well. We add value to customers' business

by innovative designs and products that will provide competitive advantage over your rivals.

Capable of ultimate one stop solution

There are various of products ranges, flexible order quantity, customized designs. Our products are capable of ultimate

one stop solution for different sizes of projects and business. With pre-sale and after-sale assistance, prompt delivery,

we care the customers' satisfaction and benefits.

Sales Service Networks

FAQ

Q1. Is Jwell Machinery a Manufacturer?

A1: Yes, We own 5 manufacturing bases and sales center in Shanghai , Suzhou ,Changzhou, Zhou Shan, Dongguan China.

Jwell made the first Chinese screw and barrel in 1978 in brand name Jinhailuo.After more than 40 years development,

JWELL is one of the biggest extrusion machine supplier in China with 300design&test engineer, 3000 employees.

Jwell has become the premier supplier of extrusion lines and reliable business partners. Welcome to drop in us.

Q2: How many brands does Jwell Machinery own?

A2: Jwell Machinery owns more than 20 subsidiaries, China famous brand JINHAILUO, JWELL, BKWELL, DYUN

are our Trade Marks.

Q3: If we don't find what we need from your website , What should we do ? Do you make extrusion lines as per

customers' specific requirement?

A3: Yes, we can provide bespoke service to customers with specific requirements. You can send the detailed

requirements by email. We will check if we can develop them. We develop new machinery every month, and

some of them may not yet be updated on our website.

Q4: How do you ensure your machinery and service quality?

A4: Our machines taking the European standards and follow the Germany type of business, we cooperation with

International famous brands Siemens Schneider Flender Omron ABB WEG Falk Fuji etc. Our company continuously

imports over 1000 international first-class high precision processing equipment such as multistage machining centers, CNC lathes and CNC milling machines from Korea, Japan etc. All our processes strictly adhere to CE certification,

IS09001 and 2008 quality management system . And we have 12 months quality warranty time. We testing the

machine performances before each delivery. Jwell service engineers will always be here for anything you needed.

Q5: How can I order and make payments?

A5: Once clear your requirements and determined extrusion line is ideal for you. We will send technical solutions and

Proforma Invoice to you. You can pay via TT bank transfer, LC as you like.

Q6: If we find your bank account or email different as before, how should we respond?

A6: Please don't send the payment and double check with us before arrange payment (Bank details will be listed in

every piece of proforma invoice. ) We are only responsible for email " " .

Q7: How long is the delivery date?

A7: Usually it takes about 1 - 4 months depends on different machinery upon receipt of order advance payment.

Q8: What is your Minimum Order Quantity?

A8: One. We provide both customized extrusion lines and technical solutions. Welcome contact with us for technical

innovation or improvements for your future purchasing plan.

Q9: What is your production capacity?

A9: We produce more than 2000 advanced extrusion lines every year world wide.

A10: What about shipping?

Q10: We can send the small spare parts by air express for urgent matter. And the complete production line by sea

to save the cost. You can either use your own assigned shipping agent or our cooperative forwarder. The nearest

port is China Shanghai, Ningbo port, which is convenient for maritime transportation..

Q11: Is there any pre-after sale service?

A11: Yes, we support our business partners by pre-after sale service. Jwell has more than 300 technical testing

engineers traveling world wide. Any cases would be responded with prompt solutions. We provide training, testing,

operation and maintenance service for a life time.

Q12:Are our business& money safe with Jwell Machinery ?

A12: Yes, your business is safe and your money is safe. If you check China company blacklist, you will see that it is

not contain our name as we never crook our customer before.

Please click "send" and Contact us !!

Shanghai Jwell Machinery Co., Ltd.

Add: Changzhou, Suzhou, Dongguan, Zhoushan, Shanghai of China.

Contact: Ms. Megan Jwell

Mob:+86 13818591226

Web: jwellmachinery.en.made-in-china.com

Jwell Plastic Multi-Layer Stone Composite (SPC) PVC floor production line (1050 1220 mm)

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23