Plastic Pelletizer Strand Granules Cutter

ShunDe Jiatian Hard Tool Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. LQ Production Capacity as RequireProduct Description

Parameter Table| Type | Model | Power | Cutting strand | Granules size(mm) | Max output(kg/h) | Knife number | Rollor length (mm) |

| cantilever | LQ-25 | 0.75 | ≤3 | φ3×3 | ≤40 | 14 | φ60×50 |

| gantry | LQ-60 | 1.1~1.5 | ≤8 | φ3×3 | ≤60 | 14 | φ120×96 |

| cantilever | LQ-300 | 3~4 | ≤14 | φ3×3 | ≤300 | 32 | φ200×100 |

| gantry | LQ-300 | 3~4 | ≤18 | φ3×3 | ≤300 | 24 | φ100×150 |

| cantilever | LQ-500 | 5.5~7.5 | ≤30 | φ3×3 | ≤500 | 32 | φ120×200 |

| gantry | LQ-500 | 5.5~7.5 | ≤30 | φ3×3 | ≤500 | 32 | φ100×200 |

| gantry | LQ-900 | 11~15 | ≤40 | φ3×3 | ≤900 | 32 | φ100×300 |

| gantry | LQ-2000 | 15~22 | ≤60 | φ3×3 | ≤2000 | 32 | φ120×400 |

Function:

Planer type pelletizer is fit to pelletize glass fibre , minerial, enhanced plastics, rubber mixer, PVC, PBT, PA,PP,PE,PS,PET, ABS and other plastics strand pelletizing.

Detailed features:

Cantilever granulator with unique structure,easy maintance,low nosie,high production efficiency,long service life.

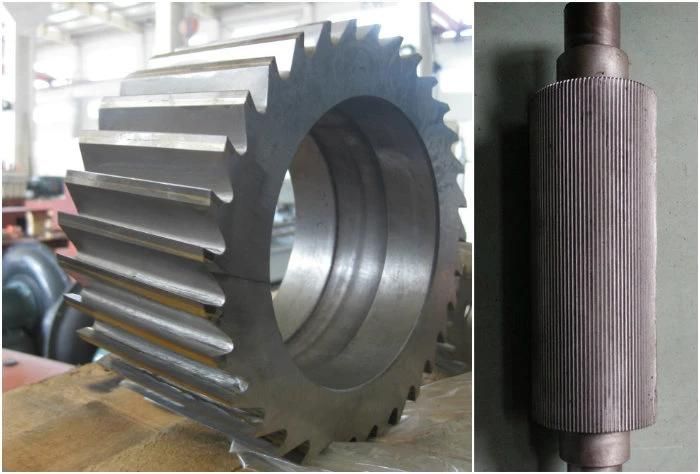

Adopt independent pelletizing chanber design,convenient to change color and clean-up remained-material.Cutting tool material are all hard alloy cutter,the more rotary cutter quantity,higher abrasion resistance ,diced evenly, cut flat.

Granulator uses polyurethane roller traction,higher tensile strengh,steady traction,It is suitble for cooling strands pelletizing of high -yield,high strengh engineering plastics, espencially for srands pelletizing of glass fiber reinforced plastic

Company introduction :

Nanjing Haisi Extrusion Equipment Co., Ltd. is a High-Tech company. Our firm is composed of a strong team which has substantial experience in R&D, design, manufacture, technique and sales service and has specialized in extruder industry for many years. We are now devoted to highly active single / twin screw compounding extruders and interrelated techniques. According to the material system and technical process, we achieve the optimization of structural design for mixing equipment and combine electromechanical and technique systems together, which show our many years' experience and comprehensive techniques.

Our products are single screw extruders, co-rotating twin-screw compounding extruders, auxiliary equipment, etc.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23