Oil Drilling Diamond PCD Cutter Tricone Drill Bit

SHANDONG YAXIN PLASTIC PACKING CO., LTD. / 2022-06-27

- Type:Polycrystalline Diamond Compact

- Blade Material:Diamond

- Name:PDC for Oil Drilling Industry

- Certification:ISO9001

- Service:Talentool OEM,ODM Services

- Size:46*3.2mm

=== Base Info ===

- Model NO.:wanke

- Transport Package:Carton

- Specification:A

- Trademark:wanke

- Origin:Henan China

- HS Code:8207901000

- Production Capacity:5000PCS

=== Description ===

PDC cutter is mainly used in the exploration and exploitation of oil& gas, mining and the cutting of other areas.

PDC cutter is made up of polycrystalline diamond layer and Tungsten Carbide Substrate. Thus it has high wear resistance, impact resistance and thermal stability.

Structure of PDC cutter |

| PDC cutter is made through the sintering of synthetic diamond powder and tungsten carbide substrate under the condition of high temperature and pressure. PDC cutter has very high wear resistance, impact resistance and thermal shock resistance because diamond is the hardest material in nature and it has good thermal conductivity. |

Round Shape PDC cutter

Polycrystalline diamond compact PDC cutter is mainly made of diamond powder and cobalt metal powder.

Our connect feature is mesh, it is very strong , not easy to take off.

Working life is longer than others.

Square Shape PDC cutter

PCD work layer & tungsten carbide part is used mesh connect method to make it stronger.

When using PDC, PDC work layer is not easy to take off and more abrasive resistant.

PDC cutter used for oil drilling bit

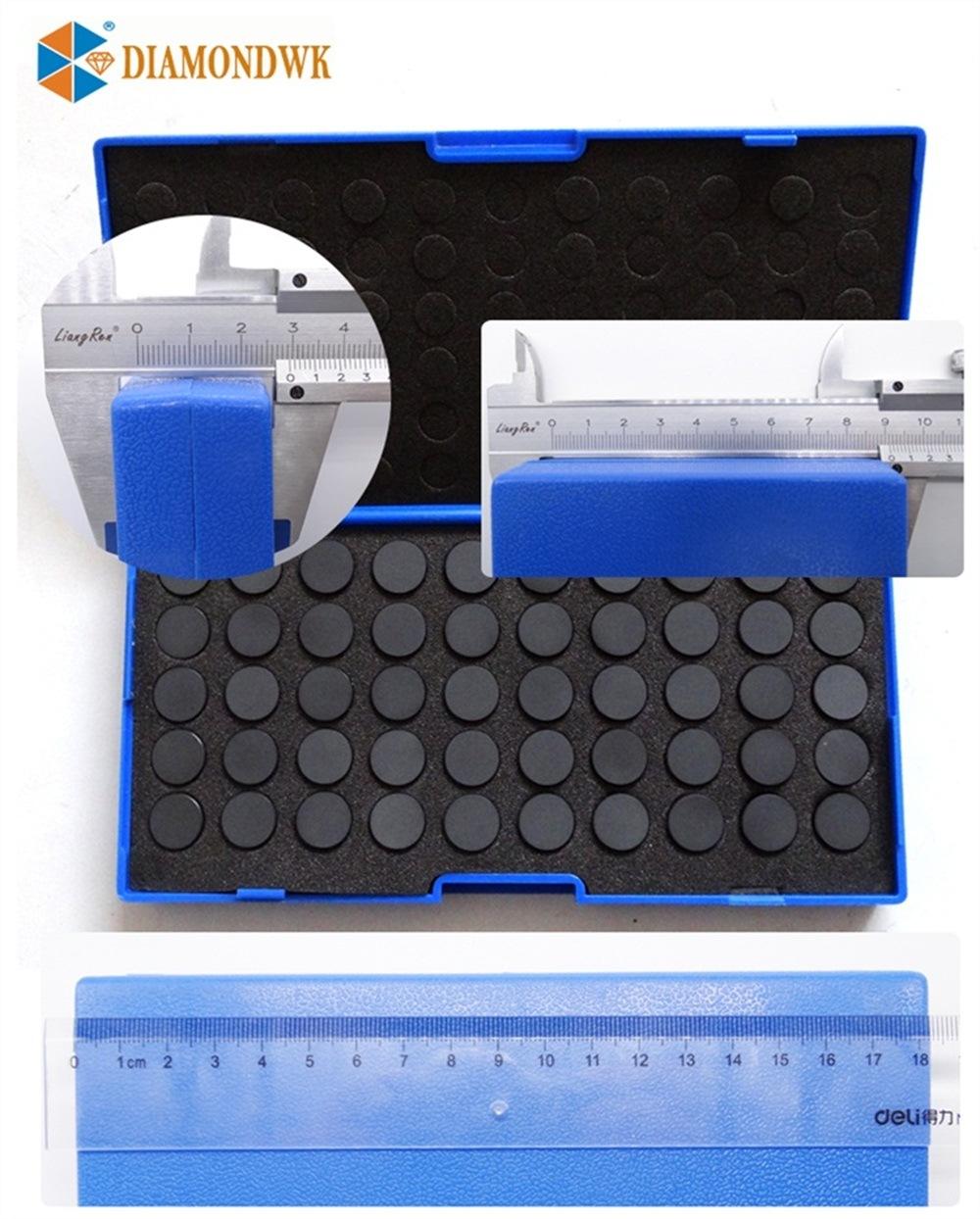

Package Of PDC Cutter

Why choose us?

1. DIAMONDWK is a highly professional manufacturer in PCD & PDC field

2. Rich experience in OEM order.

3. Advanced production equipment.

4. Own design team, can help you custom the packaging.

5. Own provincial engineering technology center.

6. D&B and ISO9001 certificates

DIAMONDWK is a professional synthetic diamond powder, PDC cutter, dies blank company integrating development, production and sales. Factory

located in middle of China-Henan, with more than 124000 square meters. "High quality products, competitive prices, and classic services" is the soul of our

business.Warmly welcome all partners to join DIAMONDWK for mutual benefits cooperation.

PCD cutting tools mainly used for processing non-ferrous metal like copper, aluminum, zinc, alloy and others, also used for processing rubber, plastic, bakelite, etc

It is better than natural diamond of resistance to impact, and its abrasion resistance is over100 times than superhard alloy . Suitable for nonferrous metallic and nonmetallic material processing. PCD cutting is not suitable for processing ferrous metals commonly.

Application

Process of ceramic, carbide, tungsten and other highly abrasive materials and parts

Process of high silicon aluminum alloy, wood, glass, ceramic, other abrasive materials and parts.

Process of silicon aluminum alloy, plexiglass, ceramic and non-ferrous metals.

Process of silicon aluminum alloy, plexiglass, and non-ferrous metals.

Features

Super high abrasion resistance, the content rate of diamond powder is above 95%, long service life

High abrasion resistance and impact toughness, used for lager cutters

Higher abrasion resistance and impact toughness, fine surface finish

High impact toughness and better abrasion resistance, uniform surface finish, used for larger cutters.

Packaging & Delivery

Packing details: 10 pcs/ packet in Rose plastic boxes

Delivery Time: 7 days

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23