30L ~ 60L Automatic Extrusion Blow Molding Machine (PXB120dB)

Shandong Fangdi Trade Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. PXB120DB Bottom Blowing Available Material PP, PE, ABS... Total Weight 26t Output(Dry Cycle) 500*2 PC/Hr Die Head Option Accumulator Head Transparent Line Available Production Usage Toys, Bottle, Auto Parts, etc Multi-Layer Available Multi-Color Available Screw Diameter 120mm Transport Package Film Packing with Wooden Bottom Specification Max capacity 60L Trademark Puxin Origin Jiangsu HS Code 847730100Product Description

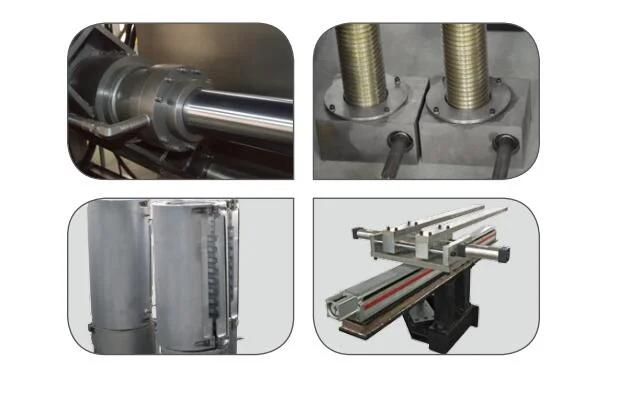

PXB120DB30L-60L Double Station Blow Molding Machine

- Fixed Opening-Closing Clamping with 6.6L Accumulator Head Capacity

- Perfect Usage for production of Big toys, auto parts, Jerry Can, sprayer and so on.

- Hydraulic Servo System control with quick action speed.

- High capacity amount with energy saving.

Configuration List

| PLC | MITSUBISHI | Japan |

| Touch Screen | HITECH | Taiwan |

| Inverter | MITSUBISHI | Japan |

| Power Supply | MEAN WELL | Taiwan |

| Relay | OMRON | Japan |

| Hydraulic Valves | YUKEN | Japan |

| Hydraulic Pump | YUKEN | Japan |

| Contactors | LS(LG) | Korea |

| Solid relay | FOTEK | Japan |

| Breaker | LS(LG) | Korea |

| Temperature Control Module | MITSUBISHI | Japan |

| Oil Sealing | DZ | Taiwan |

| Oil Tube | LIEBAO | Taiwan |

| Transducer | GEFRAN | Italy |

| Proximity Switch | SONON | China |

| Motor | SIEMENS | China |

| Air Valve | FESTO | Germany |

| Parison Controller | Moog | Japan |

| Servo Valve | Moog | Japan |

| Material | PE,PP,ABS... | |

| Max container capacity | L | 60 |

| Output(dry cycle) | pc/hr | 500×2 |

| Machine dimension(L×W×H) | M | 5.7×2.6×4 |

| Machine weight | T | 26 |

| Clamping Unit | ||

| Clamping force | kn | 360 |

| Mold platen size(W×H) | mm | 960×980 |

| Platen opening stroke | mm | 450-1050 |

| Platen moving stroke | mm | 600 |

| Max mold size(W×H) | mm | 700×1080 |

| Mold thickness | mm | 460-600 |

| Power | ||

| Servo oil pump motor power | KW | 15 |

| Servo pump displacement | L/MIN | 100 |

| Blow pressure | MPA | 0.8 |

| Air consumption | M3/MIN | 1 |

| Cooling water pressure | mpa | 0.3 |

| Water consumption | L/min | 90 |

| Average energy consumption | KW | 85-95 |

| Extruder unit | ||

| Screw diameter | mm | 120 |

| Screw L/D ratio | L/D | 25 |

| HDPE Melting capacit for HDPE | kg/hr | 240-300 |

| Number of heating zone | zone | 5 |

| Screw heating power | kw | 21.4 |

| Screw fan power | KW | 0.5 |

| Extruder motor power | kw | 90 |

| Die head | ||

| Number of heating zone for single die head | zone | 4 |

| Heating power for single die head | kw | 21.3 |

| Max die-pin diameter | mm | 350 |

| Accumulator capacity | L | 6.6(7.6) |

| (HDPE) Accumulator weight(HDPE) | KG | 4.95(5.7) |

Delivery Time:

- No later than 60 days after receipt of the deposit

Training:

- We provide training service for two or three operating men for free (but the cost for trainer's board and lodging is not included).

Installation:

- The supplier will send one specialist to test run the machine until it is running in normal state.

Guarantee:

- Our guarantee is valid for a period of 12 months. If the malfunction caused of the machine's self quality, we will troubleshoot it for free.

Auxiliary Equipments:

- Auxiliary equipments and moulds for production line are available and optional, please kindly ask for quotation.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23