WPC Foamed Board Extrusion Line/Plastic Machine/Extruder

Kunshan Canuri Precision Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. 80 156 80 172 92 188 Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Machine Name WPC Extrusion Line Payment Tt Main Motor 75kw Package Plywood Pallet Warranty 12 Months Certificate ISO SGS CE Transport Package on Demand Specification 1220x2440mm Trademark SanYi Origin China HS Code 847780000 Production Capacity 350-400kg/HProduct Description

The only professional manufacturer in PVC foam board machine in China

WPC construction board making machine

1. SJSZ 80/156 Conical twin Screw Extruder

ABB frequency converter, Siemens contactor, OMRON Japan, Motor power: 75KW

2. Calibration unit

Calibration plate: 1500mm× 500mm 4couples

3. Cooling tank and bracket

Length: 6000mm

Trimming knife: 3 sets

4. Haul-off unit

8 couples

Cylinder clamping and loosening

5. Cutting unit

6. Stacker

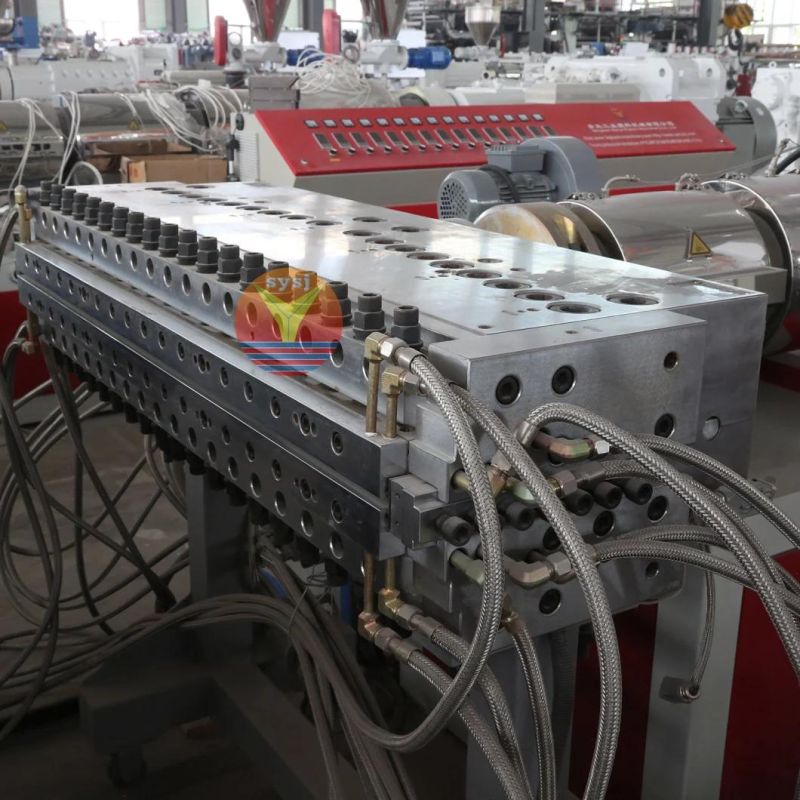

7. Mould (T-Die )

Nature and Advantage of Wood-plastic Construction board

Compound wood is with the plant fiber (sawdust, wood chip, bamboo flocks, straw, wheat straw, peanut shells, coconut shells, etc) as raw material, according to pretreatment, make it compound with PVC to from a new type environmental protection material.

The characteristics of PVC wood-plastic buliding template:

(1)Widely source materials, low price, old material or mixture materail is ok;

(2)Wood-plastic can free adjust product techinque and formula according to request so as to produce different performance and shape material, the utilization rate of profile close to 100%

(3)The wood/plastic additives of wood-plastic material are safely, avirulent and harmless, its also won't produce side effects, so it can't constitute any harm to our body and enviroment

(4)Low maintenance fees, and the using time is longer than simple wood

(5)Wood-plastic material products and recycling waste can be 100% recycled, and will not affect the product performance.

(1) With excellent physical and chemical characteristics, a similar wood appearance, good stability than wood, won't produce crack, warping, no wood scarring, twill, high hardness, the using life is long;

(2) With a similar wood secondary workability, It can be saw, plane, adhesive, can be fixed by nails or screw, easy to maintenance;

(3) Without worm eaten, acid and alkali resistant, corrosion resistance, small water imbibition;

(4) Products can recycle, also can degrade, it is good for environment

(5) Wood-plastic template combine the nature of wood and plastic, have a wide range application.

our exhibtion

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23