PC Sun Sheet Extruder

Ningbo Conwhole Hardware Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

1.PRODUCT INTRODUCTION

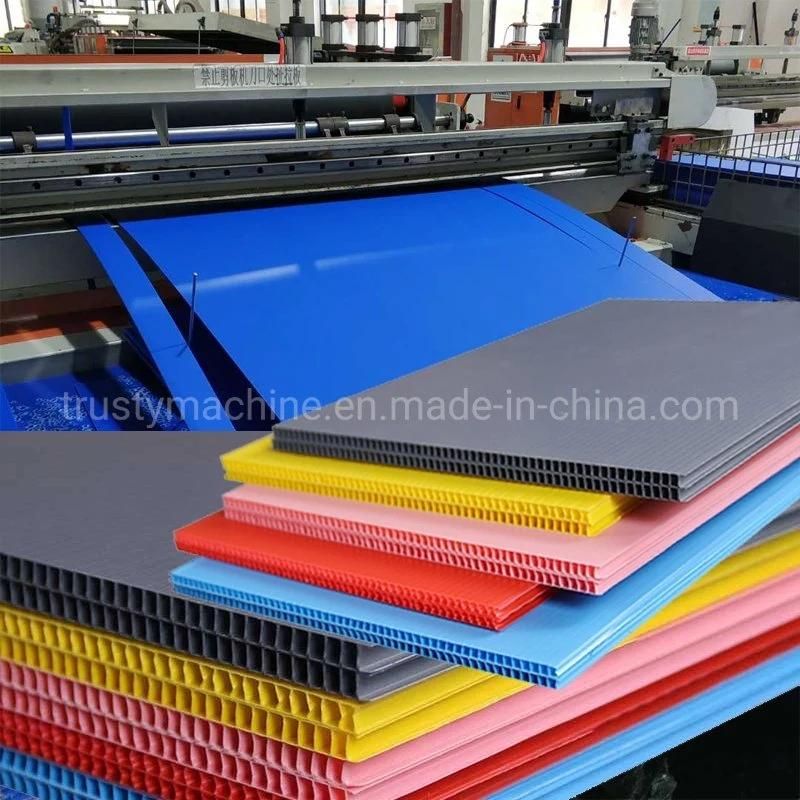

PC sunshine board, also known as polycarbonate hollow board, glass capron board, polycarbonate board, etc., is made of high-performance engineering plastic polycarbonate resin, which has high transparency, light weight, impact resistance and sound insulation , Heat insulation, flame retardant, anti-aging and other characteristics, but not acid and alkali resistant. It is a high-tech, comprehensive performance, energy-saving and environmentally friendly plastic sheet.

PC sunshine board is a picture of the plastic building material pc greenhouse board that is widely used internationally. It has the incomparable advantages of other building decoration materials (such as glass, plexiglass, etc.), and it is called "unbreakable glass". Widely used in greenhouses/industrial plants, decoration, advertising signs, parking sheds, passageway lighting rain poncho residences, commercial building lighting canopies, exhibition lighting, sports venues, swimming pools, warehouse lighting roofs, factories, stadiums, lighting canopies and sunshades, Agricultural greenhouses, aquaculture and flower greenhouses, as well as public facilities such as telephone booths, newsstands, stations, highway sound insulation, advertising and decoration fields.

2.Features

(1) Light transmittance: The light transmittance of PC board can reach up to 89%, which is as beautiful as glass. UV-coated panels will not produce yellowing, atomization, and poor light transmission under sunlight. After ten years, the loss of light transmission is only 6%, the loss rate of PVC is as high as 15%-20%, and the glass fiber is 12 %-20%.

(2) Impact resistance: The impact strength is 250-300 times that of ordinary glass, 30 times that of acrylic plates of the same thickness, and 2-20 times that of tempered glass. There will be no cracks when falling two meters under a 3kg hammer. The reputation of "glass" and "sound steel".

(3) Anti-ultraviolet: One side of the PC board is plated with an anti-ultraviolet (UV) coating, and the other side has an anti-condensation treatment, which integrates anti-ultraviolet, heat insulation and anti-drip functions. It can block ultraviolet rays from passing through, and is suitable for protecting valuable artworks and exhibits from damage by ultraviolet rays. There are also PC boards made with a double-sided UV special process, which is suitable for special flower planting and environments with higher requirements for UV protection.

(4) Light weight: the specific gravity is only half that of glass, saving the cost of transportation, handling, installation and supporting frame.

(5) Flame-retardant: The national standard GB50222-95 confirms that the PC board is flame-retardant grade one, that is, grade B1. The ignition point of the PC board is 580ºC, and it will self-extinguish after leaving the fire. It will not produce toxic gas during combustion and will not promote the spread of the fire.

(6) Flexibility: According to the design drawing, cold bending method can be adopted on the construction site, and it can be installed into an arch, semi-circular roof and window. The minimum bending radius is 175 times the thickness of the adopted plate, and hot bending is also possible.

(7) Sound insulation: The sound insulation effect of PC board is obvious, and it has better sound insulation than glass and acrylic board of the same thickness. Under the same thickness, the sound insulation of PC board is 3-4DB higher than that of glass. Internationally, it is the material of choice for highway noise barriers.

(8) Energy saving: keep cool in summer and keep warm in winter. PC board has a thermal conductivity (K value) lower than that of ordinary glass and other plastics, and its heat insulation effect is 7%-25% higher than that of the same glass. The heat is up to 49%. Thus, the heat loss is greatly reduced. It is used in buildings with heating equipment and is an environmentally friendly material.

3.USED FOR

1)It is suitable for the exotic decoration of gardens and entertainment venues and the corridors and pavilions of resting places;

2)Suitable for interior and exterior decoration of commercial buildings and curtain walls of modern urban buildings;

3)Suitable for aviation transparent containers, front windshields of motorcycles, airplanes, trains, ships, automobiles, motorboats, submarines and glass military and police shields;

4)It is suitable for the layout of telephone booths, advertising street signs, light box advertisements, and display exhibitions;

5)Suitable for instruments, meters, high and low voltage switch cabinet panels and military industry, etc.;

6)Suitable for high-end interior decoration materials such as walls, ceilings, screens, etc.;

7)Suitable for noise barriers on highways and urban elevated roads;

8)Suitable for agricultural greenhouses and breeding greenhouses;

9)Suitable for modern ecological restaurant ceiling; PC sunshine board

10)It is suitable for bicycle sheds, balcony sunshades and roof rest pavilions in all units or communities;

11)It is suitable for lighting ceilings of office buildings, department stores, hotels, villas, schools, hospitals, stadiums, entertainment centers and public facilities.

4.ABOUT US

Qingdao Trusty Plastic Machinery Co., Ltd. is a professional plastic extrusion equipment manufacturer integrating design, research and development, production and sales.

The company's main products are rich, the production technology is mature, and the after-sales service is guaranteed. Products are sold at home and abroad, such as: Brazil, Chile, Mexico, the Philippines, Italy, Russia, Pakistan, Vietnam, India, Algeria, Egypt and other countries.

Our company is located in Qingdao, one of the plastic machinery bases in China, where the railway, sea transportation, aviation and other transportation systems are very complete. And it is one of the regions with rapid economic development in the coastal cities.The advantaged geographical conditions have provided great convenience for the development of the company's trade.

Our company's main products are: PVC door and window profile production line, WPC wood-plastic profile production line, PVC wall panel production line, PVC/PE/PPR pipe production line, PVC/WPC crust foam board production line, PE/PP/PC hollow sheet production line, PVC roof tile production line and PET packing belt production line, etc. According to customers' needs, to achieve diversified processing customization.

Over the years, the company has always adhered to the tenet of "honesty for basis, quality for living, innovation as the theme, and development as the focus", abide by the quality commitment to users, and won the trust of customers.

5.FAQ

1.WHY CHOOSE US

We are the Professional manufacturer to develop the plastic extrusion machines in Qingdao. Machine quality and customer satisfaction is our pursuit.Be sure we have the strength to provide you with quality machines and perfect service.

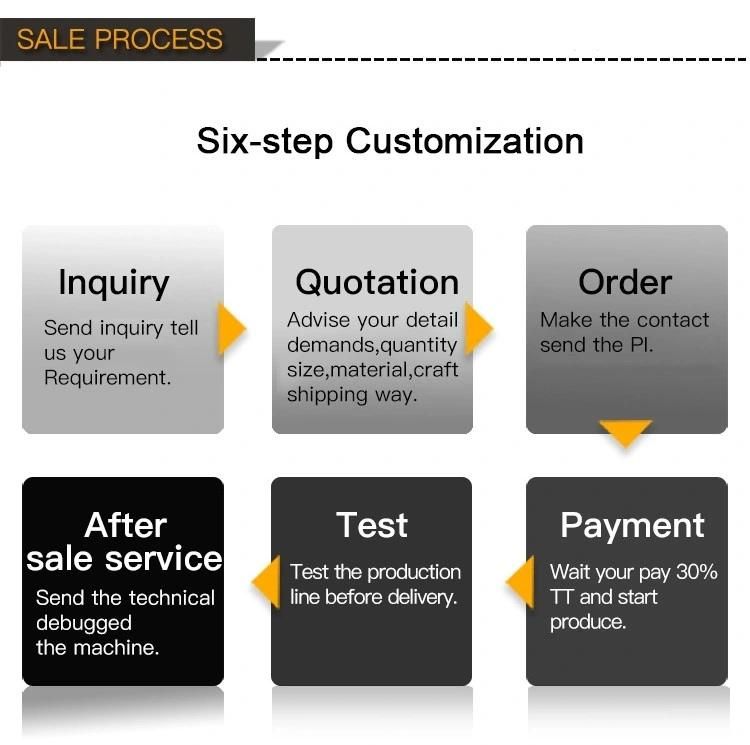

2.WHAT SERVICES DO WE OFFER?

Pre-sale communication → Design proposal, signature confirmation→

Customized production→ Test machine before shipment →Package &

delivery→ Engineer installation→Training operator → Technical support

3.PAYMENT TERMS:

30% of total amount should be paid by T/T as down payment ,the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C by payment(at sight).

4.DELIVERY CONDITIONS:

4.1 Delivery condition: FOB Qingdao port or CIF destination Port.

4.2 Delivery terms: Within 30-60 working days after receipt of advanced payment, the seller should inform the buyer to do inspection,the seller should finish packing of goods and ready for shipment within 15 working days after the seller receipt the full payment.

5.WARRANTY TERMS

5.1 Warranty period: 12 months, starting from the machine receipt in customer's warehouse

5.2 Seller shall grant: services and spare parts, free-of-charge service throughout the entire equipment during warranty period.

5.3 long life service: the seller should provide long life service for the sold goods, the buyer pay for needed spare parts after the 12months warranty terms.

6.INSPECTION

When the machine finished, the seller should inform the buyer to do inspection before shipment, the seller guaranty good performance of all the sold goods.the seller undertake the material cost for the machine inspection in seller's factory. the buyer should come to seller's factory to do the inspection work, or the buyer could entrust any third party to come to seller's factory to do the inspection work.

7.INSTALLATION AND EQUIPMENT COMMISSIONING:

if the buyer requires, the seller should send technician team to buyer's factory for installation and testing the whole line, and the buyer should undertake the whole food/place and round tickets (airplane, food, hotel, and so on), and pay salary to engineer for 100 usd/day/engineer.

6.AFTER SALES SERVICES

| Technical documentation |

| All symbols on the equipment will be in English. We will be responsible for providing the Buyer with a general layout plan, electrical plan, installation orientation and manuals, in English. |

| Arrangements for inspection, installation and testing of the equipment |

| a. After all of the equipment is delivered to the customer's factory, the Buyer shall be responsible for all preparation work, e.g. electricity supply, water supply, cranes and labor, etc. b. We will prepare visa applications for their engineers, who will assist in the equipment installation and testing at the Buyer's factory. c. The Buyer will buy a round-trip air ticket for the engineer(s) after the visa application is approved. The Buyer is responsible for all expenses generated, e.g. visa application fees, meals, accommodation and an allowance of $80.00 per day for each engineer. d. The engineer(s) will provide free training for the operators and maintenance people, in Buyer's factory. e. If the Buyer does not request commissioning by our engineer(s) within four months from the date of the bill of lading, it will be accepted that all the equipment has been successfully tested and approved by the Buyer. |

| Quantity and quality guarantee |

| a. In cases of quantity discrepancies or equipment damage, at the destination, the Buyer will file a claim within 30 days after the arrival of the goods at its destination. The insurance company and the shipping company will be responsible for all discrepancies and damage caused by the shipping company or other transportation companies. b. Guarantee period and after-sales services: 13 months from the date of the bill of lading. During this guarantee period, if there is a quality issue, we will provide spare parts without charge. If malfunctions are caused by the Buyer's improper operation of equipment, we will provide the Buyer with spare parts at cost prices. c. Long-term service: Beyond one year, we will provide the Buyer with spare parts at reasonable prices and provide long-term technical guidance. |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23