Garbage Bags HDPE Film Blowing Machine

Huzhou Gu's Imp. & Exp. Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Application:

It is used for blowing the various plastic film of low density polyethylene(LDPE) and high density polyethylene (HDPE) color striped plastic film, etc,

Which are widely used for packing food, fruit, garments, textile, daily necessities and other civil and industrial products.

Characteristics:

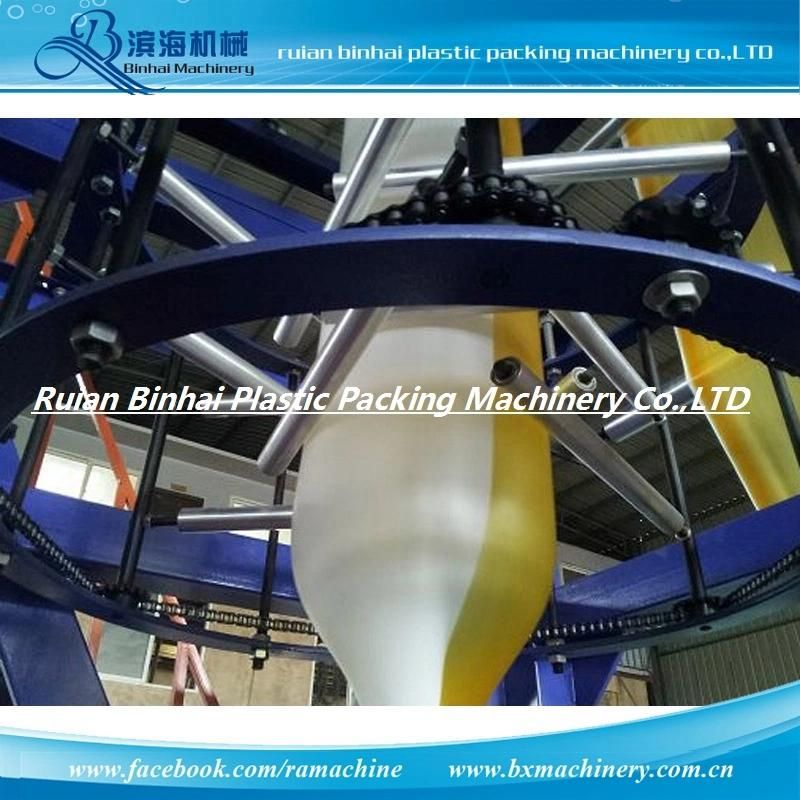

The cylinders and the screw stems of model SJ-45*2 extruder are made of high-quality alloy steel with optimum hardness and strong corrosion resistance after precision finishing and nitrogen treatment.FM-600 auxiliary machine can be freely adjusted within the limits of 700mm according to the technological requirements of different materials, and has is fitted with a plug-in plate mechanism for making vest bag ,The coiling unit adopts torque motor to keep proper tension and make rolling even and roll-changing easy.HDPE

Single Screw Film Blowing Machine

Main Technical Parameters For Plastic Film Blow Machine

BH-SJ60

(L×W×H) mm

Pictures are 800mm , 50 # Screw For HDPE Film, LDPE Film Blowing Machine .

----Make Tube Film Rolls

----If your Film is HDPE , Suggest Rotary Head Die (Optional )

---If your film is Single Layer For Side Seal bags, suggest Double Winders+Slitter. (Optional )

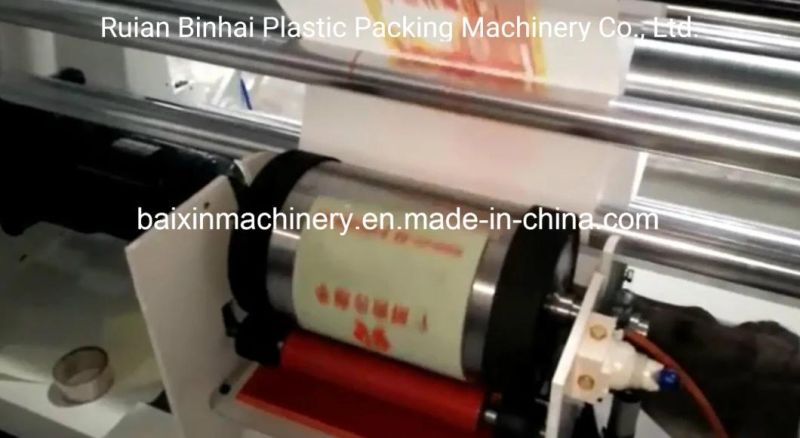

-- If Your Film need Printing , need Corona treatment . (Optional)

This is mini printer we installed on Film blowing machine.

---Single Color

----- 300mm

Welcome to click learn more information from AMY Yu , thanks

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23