PPR-Al-PPR Pipe Making Machine/Pipe Production Line/Pipe Extruder

Nanjing Lite Hydraulic Technology Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Machine features:

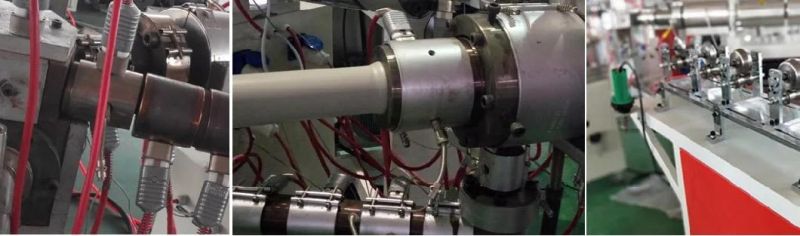

Inner 3-layer co-extrusion die head

1)Inner 3 layer co-extrusion die head is for extruding inner PPR layer+inner adhestive layer+ Aluminum tube.

2)Mature co-extrusion and altrasonic welding technique integrated with a completely automatic control system.

3)Using Stable imported Ultrasonic Welder, which ensure the PE-AL-PE pipes can be produced in stable welding condition.

4)One-step realizes the co-extrusion of inner plastic layer and the aluminum layer. The Min aluminum strip thickness is 0.15-0.3mm, the production speed is 15m/min.

Outer 2 layers co-extrusion die head

1)The inner and outer pipes adopt a step-by-step co-extrusion process, which improves the bonding strength between the pipes,

2)avoids heat accumulation between the pipes, and ensures smoother surfaces of the inner and outer pipes.

PPR-AL-PPR pipe cutting device:

1)Flying knife cutting machine is used when pipe diameter≤32mm.

2)Siemens servo motor driving, response rapid , it can really realize the fast cutting of small diameter pipes.

3)Different specifications and sizes, equipped with special guide sleeves

4))When customers produce 4m or 6m long straight pipes, they can achieve (cutting) accuracy with an error of ≤1mm. The signal transmission is fast, the response is sensitive, and it can really realize the fast cutting of small diameter pipes,

The pexb-al-pexb pipe production line includes:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23