Palm Kernel/Peanut Oil Processing Machine

Shenzhen Xiangfeizhu Technology Co., Ltd. / 2022-07-05

- Type:Pressing Machines

- Application:Flour, All, Beans, Wheat, Starch, Rice flour, Palm Kernel

- Voltage:380V

- Appearance:Horizontal

- Press Materials:Palm Kernel

- Press Series:Second

=== Base Info ===

- Model NO.:HT-PKO

- Condition:New

- Customized:Customized

- Capacity:10-100t,H

- Color:Red, White or Customized

- Warranty:12 Months

- Material:SUS304,316

- Press Material:Seed and Nut

- Function:Making Palm Oil

- Quality:Top Level

- Weight:up to Specification

- Transport Package:Nude Packing

- Specification:ISO9001, CE, SGS, IAF, CNAS

- Trademark:HUATAI

- Origin:Henan, China

- HS Code:8479200000

- Production Capacity:20set,Month

=== Description ===

Basic Info.

Model NO. HT-PKO Condition New Customized Customized Capacity 10-100t/H Color Red, White or Customized Warranty 12 Months Material SUS304/316 Press Material Seed and Nut Function Making Palm Oil Quality Top Level Weight up to Specification Transport Package Nude Packing Specification ISO9001, CE, SGS, IAF, CNAS Trademark HUATAI Origin Henan, China HS Code 8479200000 Production Capacity 20set/MonthProduct Description

Palm kernel/Peanut oil processing machine

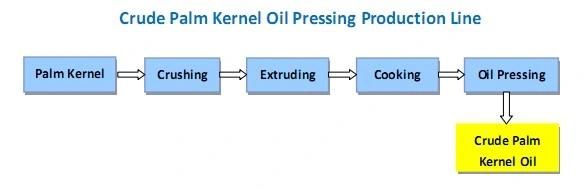

Main process in palm kernel press line:

Palm kernel Cleaning : It is used for removing the iron impurities, stone, fiber and pthers. These impurities are bad for machines, especial for the palm kernel oil expeller.

Palm kernel crushing:because the palm kernel is hard and big size, it is required to crash to smaller and even pieces. If once crashing can not reach the requirements, the second crashing is required. Crush palm kernels after softening and drying. The centrifugal crusher breaks nuts and separate palm kernel out completely.

Palm kernel and nuts shell separation. Both dry and wet separations are available. Wet separation is mostly used in palm kernel separation, on basis of difference of relative density of palm kernel and shell.

Palm kernel drying. Fresh kernel contains 20% moisture. Palm kernel has no mildew during transportation and storage while moisture drops below 7%.

Cooking section: It is used for heating and cooking the crashing materials, to make is suitable for pressing, doing like this can help final user get the maximum oil and good quality cakes.

Palm kernel oil pressing. Palm kernel oil pressing processing line is simple with usual oilseeds. The pre-pressing by oil pressing machine can obtain 1/4 palm kernel oil, and residual oil need twice pressing.

Palm kernel Filtering section: after pressing, there are some oil dregs in the crude oil, after clarifying, we need to filter the crude oil to avoid to jam the oil pipes during refining processes.

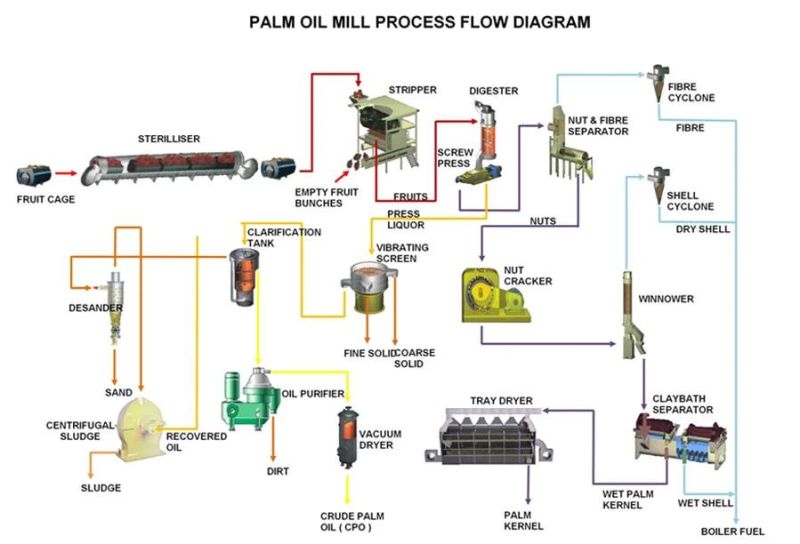

Palm Oil Mill Plant Flow Chart Introduction:

1.Palm oil mil process of bunch reception: as palm fruit unloading, cleaning, storage platform during palm oil mill processing, all hydraulic segmented discharge.

2.Palm oil mil process of sterilization: the use of high temperature to cook soft fruit bunches and sterilization, easy to separate fruit bunches, soft fruit, increasing the humidity of the fruit, it is easy to take the oil but also to make verification easier separation of the core-shell, preventing enzymatic decomposition, to avoid elevated levels of free fatty acids.

3.Palm oil mil process of threshing: strong vibrations through the fruit from fruit bunches separated.4.Mashing. Mixing tank will mash and crush palm fruit until broken after fruit threshing.

5.Palm oil mil process of pressing: There is also the steam heater in masher. The purpose of mashing is to separate the pulp and nut and crush the palm pulp. At the same time, the steam is used to cook the palm fruit and broke the cell of pulp. Because of cooking, sterilizing, threshing and mashing made the pulp soft and damage pulp cell structure, the palm pulp becomes soft and cell is broken. Then it is sent to continuous screw press. After pressing, oil palm fruit is divided into two parts: the mixture of oil, water and solid impurities, and the press cake (fiber and nut).The pulp stone separation obtained CPO and stone, press machine adopts the double screw helix continuous discharge and hydraulic, greatly improving production efficiency.

6.Fiber separation. The extrued fiber pie enters air separation system after crushed to get separation of fibers and cores.

7.Separation. Crusher divided fruit core into palm kernel and shell after separated with fiber. Air separation and washing systems separate palm kernels and shells. Shells enters boiler system as fuel, and palm kernels are storage after drying.

8.Palm oil mil process of clarification:Machine-pressed crude oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment. The oil and the sludge taken out separated (by 90% pure oil) is taken out of the oil containing 45%-55% of the water, sludge and other things.

Palm oil mil process of purification: oil purification process to improve palm oil purity.

Palm oil mil process of drying: continuous Vacuum drier with the oil out of the water, the water can be reduced to 0.1%.

10.Palm oil mil process of crushing (crusher): stone cracked open grain separation kernel and shell. In hydrocyclone, the use of kernel and core-shell particle proportion to their separation.

11.Palm oil mil process of power house: the use of diesel powered generators and turbine generators, more environmentally friendly energy production and electricity consumption to power.

12.Palm oil mil process of steam boiler: has a strong output, high thermal efficiency, stable and reliable operation, overload capacity, fuel, wide applicability, environmental protection and many other advantages. Water treatment: after setting, filtration, dosing and other processes to ensure that the water quality, but also to ensure oil quality.

13.Palm oil mil process of raw water supply: the use of remote substation technology, more energy, improve production efficiency.

Palm Oil Mill Plant Advantages:

Self-sufficient palm oil production, low production cost, low environmental pollution, recycling utilization of resource.

Palm oil mill plant adopts the most scientific palm oil processing equipment configuration, using mechanical oil pressing technology, make successfully extraction of palm oil from palm fruit.

Palm oil milling process plant covers three major plants of crude palm oil pressing plant, water treatment plant and power supply plant.

The entire palm oil process is totally environmental protective, low energy consumption, and low production cost.

Main features:

1, Our company adopts hydraulic segmented discharge in palm fruit unloading, cleaning, storage platform;

2, Palm fruit oil press machine adopts double helix hydraulic continuous discharging, greatly improving the production efficiency;

3, The use of diesel generator and steam turbine generator is more environmental protection and energy saving, electricity power for production and life;

4, Our water treatment system, through sedimentation, filtration, dosing process, ensure the quality of the water, also ensure the quality of palm oil;

5, Adopting the remote substation technology, more energy efficient, improve the production efficiency.

Specifications: 10T/H,30T/H,45T/H,60T/H,80T/H,100T/H(TON/HOUR);

Craft flow:

1.paLm fruit/bunch → sterilization → threshing → digesting → clarification → purification →dring → CPO

→ refining → decolorizing → deodorizing →RBD palm oil → crystallization → fractionation → RBD olein & RBD stearin

2.palm kernel →depericarper → crushing → pressing → CPKO → refining → RBDPK oil , RBDPK olein & RBDPK stearin

Henan Huatai Cereals and Oils Machinery Co.,Ltd.

is a company specialized in grain and oil machinery plant manufacture.

we have over 60 years experience in this line. now we have 50 engineers and 30 person's R&D team, we also cooperate with university and attract professors as our counselor. All these above is the guaranty of our machine's quality. We have 30 experienced installation engineers, they will be appointed to your country to installation and training your workers to operate the machine. Our sales team will do our best to give you suggestions and communicate with engineers to supply you the high quality machine , best service and after sales service .

Our main product :

(1) Cooking oil production line. The feedstock can be palm fruit, palm kernel, rice bran, corn germ /maize germ, sunflower seed, rapeseed, soybean seed, cotton seed, sesame and other oilseeds

(2) Grain mill production line. We can supply you different capacity from 5-1000tons wheat flour mill machine , corn mill machine and other flour mill machine, it can be whole production line or just one single machine .

(3) Biodiesel machine. Oilseeds make biodiesel machine, used cooking oil /used vegetable oil make biodiesel machine, waste plastic/tyres pyrolysis to diesel machine .

Our products sells well in global market,

and are exported to Russia,Malaysia,Kazakhstan,Thailand, Indonesia,Egypt, Philippines Russia,Kazakhstan,Uzbekistan,Tajikistan, Bolivia, Peru, Indonesia, Bangladesh, Thailand, the Philippines, Myanmar, Egypt, Sudan, Nigeria, Rwanda,Tanzania and other countries & regions,and now we have developed into a major oil machinery manufacturing base in China.

Contact person:

Mandy Zhou

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23