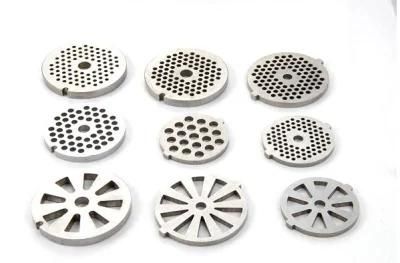

Cutting Plate Meat Grinder Plate by Powder Metallurgy Process

LAIZHOU SHENTANG CHENGXIN PACKING PLANT / 2022-07-05

- Power Source:Electric

- Process:Frozen and Chilled

- Automatic Grade:Manual

- Type:Meat Grinder

- Voltage:380V

- Customized:Customized

=== Base Info ===

- Model NO.:MG-001

- Transport Package:Carton or According to Client′s Request

- Specification:according to customers′ drawings or samples

- Trademark:HF

- Origin:Zhejiang, China

- Production Capacity:100, 000, 000, 000PCS,Month

=== Description ===

Basic Info.

Model NO. MG-001 Transport Package Carton or According to Client′s Request Specification according to customers′ drawings or samples Trademark HF Origin Zhejiang, China Production Capacity 100, 000, 000, 000PCS/MonthProduct Description

1. Our products passed TS16949 ISO-9001: 2000 quality management system verification

2. We own exquisite and advanced equipment, professional technical designer and rich producing experience

3. We can produce different size and shapes base on your drawing and samples.

4. Best quality, competitive price, shortest delivery time and good service.

5. Products are widely used at automotive part, textile machine, sewing machine, gasoline generator, power tools, oil pump rotor, clutch, oilless bearing, cu base products, stainless steels and so on.

6. If you are interested in our products and our company, please kindly let us know what you need, please donot hesitate to contact with us.

Key Specifications/Special Features

- Materials: FC0205, SUS316, SUS304, SUS420 and SUS17-4

- Surface finish: e-coating, electroplating and black oxygen

- Measuring method: 3D system

- High-lubrication, high-density and high-strength

- Accurate dimensional and strict quality control process

- Customized specifications and designs are welcome

- OEM orders are welcome

- Inspection equipment: torsion test, voltage feedback test, HRC,density test, lifting test and salt spray resistant test andmore

- Engineer consultations for production improvement and costsavings are offered

- Advantages:

- No or only little requirements for machining and the usage ofraw material can achieve 97%

- High dimensional precision

- Lower surface roughness of components

- Suitable for various raw material

- Available to make heat treatment, plating to improve partsstrength, self-lubricant and anti-friction

- Best choice for producing complex structure parts

- Suitable for large batch production

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23