PP PE PVC WPC Wood and Plastic Composite Flooring Cladding Decking Sheet Extruder Machine ...

Ningbo Easyget Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

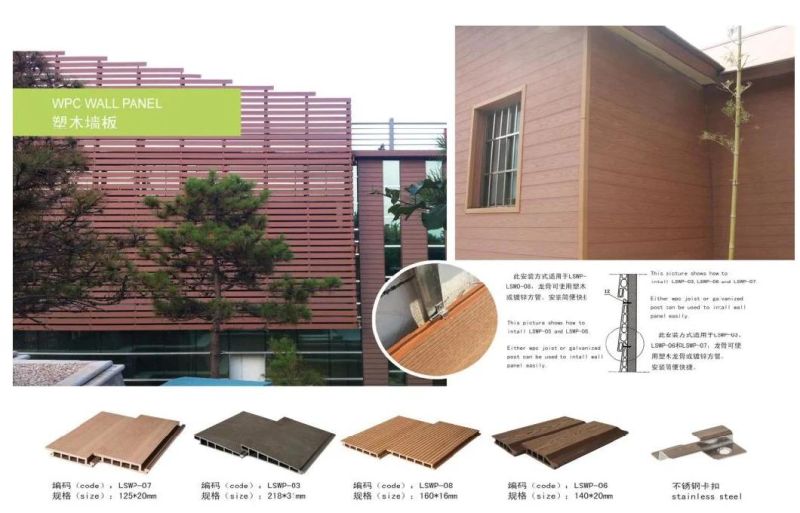

WPC furniture board, WPC construction formwork, WPC partition wall

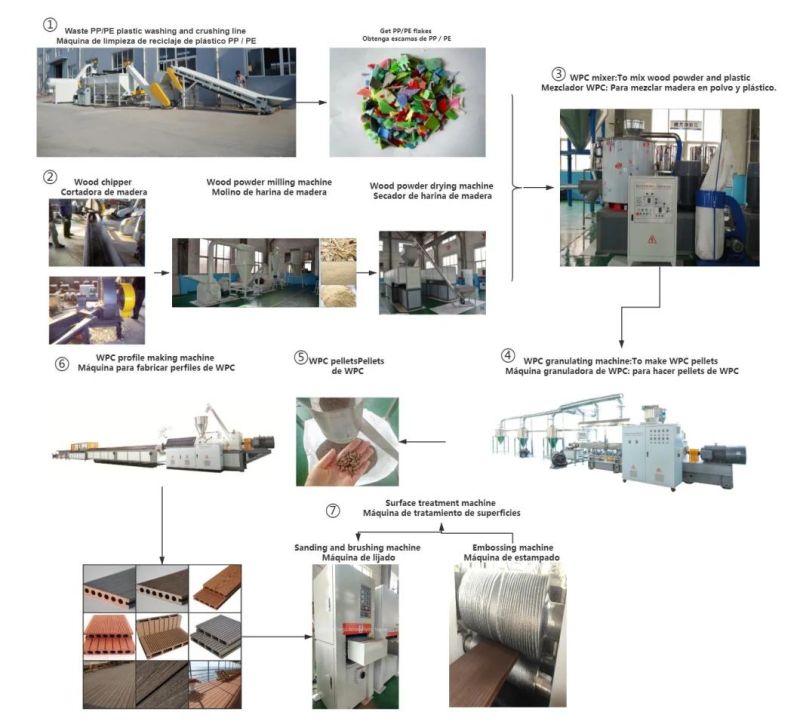

Raw material requirements of wood plastic

1, Plastic raw material: Because 200 ° C is the upper limit of the processing temperature of wood-plastic composite materials, some resins with melting points exceeding 200C, such as PET, cannot be used in wood-plastic composite materials.so generally we use PP, PE, PVC or ABS for WPC production2, Moisture of material: Water vapor can degrade the properties of the composite and also help to breed microorganisms, so it must be removed before using wood fillers. The wood filler is dried before processing. Generally, the moisture content after the treatment is less than 1 ~ 2%.

3, Chemical additives: Appropriate additives are needed to modify the surface of the polymer and wood flour to increase the interfacial affinity between wood flour and resin.

4, Percentage of wood powder

High-filled wood flour has poor dispersion effect in molten thermoplastics, making the melt fluid poor, and extrusion molding processing difficult. so we use max.70% wood content for PP PE WPC Products, and max.50% Wood content for PVC WPC products. the wood content will be reduced because of foaming technology required for PVC WPC foam board

Advantage of Wood Plastic

1. Wood-plastic products are made of wood powder + PVC plastic powder or HDPE plastic particles + other additives to form a certain shape through high temperature, extrusion, molding and other processes.2, has the appearance of solid wood and superior to the strength and arbitrariness of solid wood, and has excellent

anti-corrosion, waterproof, anti-insect, and flame retardant without solid wood. The product has no decorative pollution problems such as formaldehyde, ammonia and benzene.

3, unique formula technology, and through the interface strengthening treatment and special mixing molding technology, so that wood and plastic truly become one.

4, can be recycled, with biodegradable characteristics, protect forest resources and ecological environment, truly "green", in line with the "resource-saving, environment-friendly" social requirements.

5, like plastic non-plastic, wood-like non-wood", because it has the dual advantages of wood and plastic and avoids its

shortcomings, it has become one of the most popular environmentally friendly products in outdoor architecture in recent years.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23