PP Hollow Sheet Extrusion Line/ PP Corrugated Plate Manufacturing Machine/ Plastic ...

Ningbo Zhaoke Int'l Imp. & Exp. Corp / 2022-07-04

=== Base Info ===

=== Description ===

PP Hollow Corrugated Sheet is an extruded hollow profile, also called twin wall plastic sheet, coroplast, corflute, cartonplast.

PP hollow corrugated sheet is widely used in fields of machine,electron,appliance,food,advertising,interior decoration material,glass,agricultural product ext packing and transporting.

Process flow for PP PC hollow sheet extrusion production line

Raw material + additive → mixing → vacuum feeding machine → hopper dryer → single screw extruder → color code extruder (depend on instrusion of the sheet)→Hydraulic screen change(optional) →melt pump → T-die →Vacuum calibrator forming machine →First hause off unit →Anneal oven →Cooling bracket →Double side Corona treatment device(optional)→Second haul off unit →Cross cutter and transmission unit→Collect table

PP Hollow Machine Introductin

PP Hollow Corrugated Packing Sheet Extrusion Making Machine can produce the sheet with the width of 1000-2800mm.We can provide all auxiliary machine for plastic pp hollow sheet to make box,suas as the edge sealing machine,die cutting machine,printing machine,welding machine etc.

Processing for making PP packing box:

PP hollow sheet turnover box main material is a PP hollow sheet, and then after the pressure cut, torn edges, stitching, assembly and made of a series of processing flow.

Below is the example of processing for turnover box

1, the extrusion line produce the required PP hollow sheets with required width and thickness, and cut into required length. And collecting different sizes in different stacking.

2,Use the pressure cutting machine to cut the PP hollow sheet into required shape. Pressing action should be accurate, rapid,agile, and keep the board clean, in accordance with the provisions of a unified placed on the table.

3, the professional workers tear the extra edges according to the indentation from the pressure cutting machine, The tearing action should pay attention to the intensity. to ensure the board neat appearance, it is not allowed to produce flash and laceration because of strong tearing force.

4, stitching the two sheets by rivets, flat wire or welding, etc., the stitching seal can be sealed by fiber tape or glue or magic paste.

More details, welcome to our website.

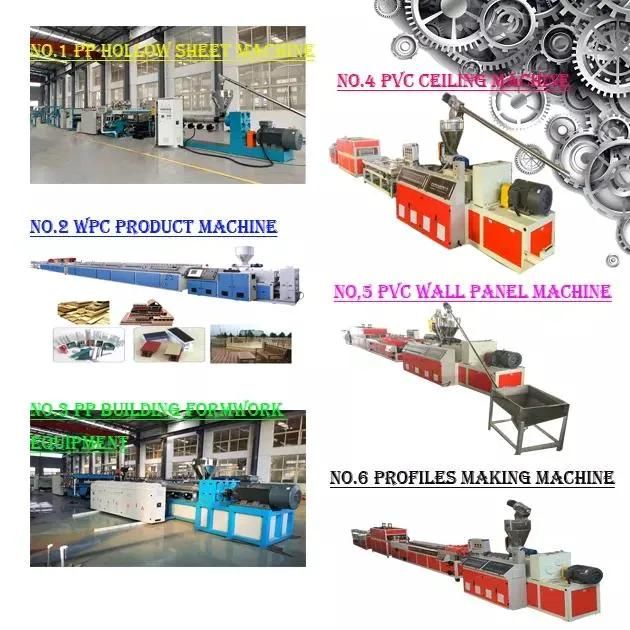

Hot sell Product

FAQWe are based in Shandong, China, start from 2013,sell to Africa(00.00%),South Asia(00.00%),Mid East(00.00%),South

FAQWe are based in Shandong, China, start from 2013,sell to Africa(00.00%),South Asia(00.00%),Mid East(00.00%),SouthAmerica(00.00%),Southeast Asia(00.00%),Southern Europe(00.00%),Eastern Europe(00.00%),North America(00.00%),Western Europe(00.00%),Oceania(00.00%),Eastern Asia(00.00%),Central America(00.00%),Northern Europe(00.00%),Domestic Market(00.00%). There are total about 51-100 people in our office.

2.what can you buy from us?

PP Building Template Production Line, PVC Decorate Panel Production Line/PVC Ceiling Panel Production Line, PVC Marble Board Extrusion Line, PVC Crust Foam Board Extrusion Line, PVC foam wood-plastic profiles machine line. 3.How about the quality about this machine?

Answer: yes,my friend,please rest assured,we have more than 15 years experience for this machine.quality is no problem 4.How about the output about this machine?is the data real?

Answer: my friend,we have tested that machine many times,then get this data,it is real and can meet your need.

5.Wether you deliver in time?

Answer: sure,once we receive your payment, then delivery immediately.

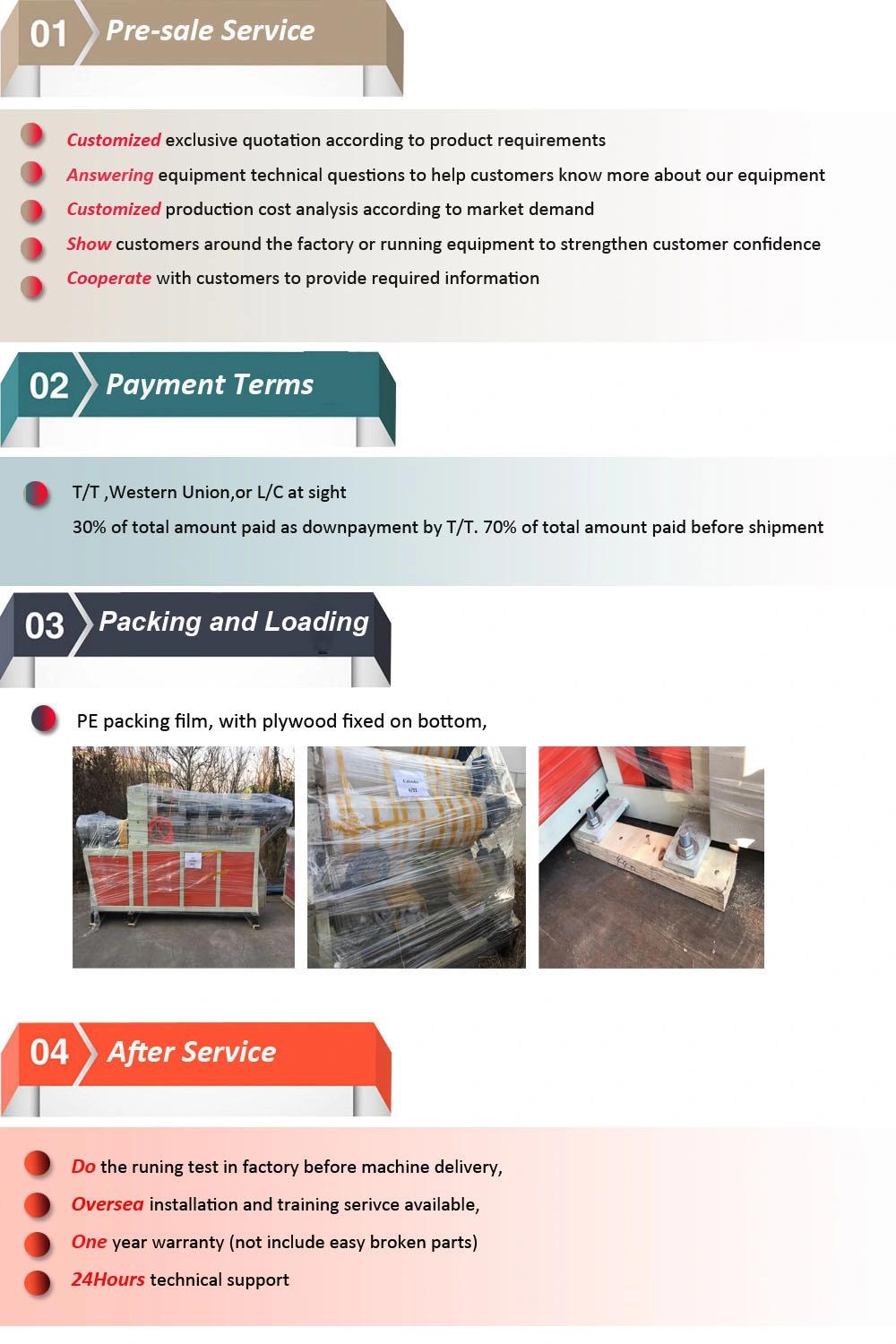

6.What about your after service?

Answer: Always final Inspection before shipment; we can send our engineers to you factory and offer long term technical guidance. 7. why should you buy from us not from other suppliers?

We have more than 10 years experience in fabricating the machine, we can fabricating the machine according to customer request. we

have good after service.

8. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,CNY, Yen;

Accepted Payment Type: T/T,L/C,Escrow;

Language Spoken:English,Chinese,Russian

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23