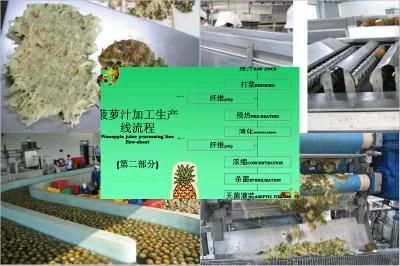

High-Proficient Typical Pineapple Production Line for Pineapple Juice, Jam or Snacks ...

Nanjing Lipack Import and Export Co., Ltd. / 2022-07-05

- Type:Juice Processing Line

- Voltage:380V

- Power:up to The Capacity and Configuration

- Customized:Customized

- Raw Material:Fresh and Good Pineapple

- End-Products Package:Clear Juice, Cloudy Juice, Juice Concentration

=== Base Info ===

- Final-Products Brix:7-12brix (for Juice),40-65(for Concentration)

- Juice Yield:65%-85%

- Capacity:100kg-10t Per Hour

- Material:Stainless Steel 304,316

- After-Sale Service:Engineers Available to Service Machine Overseas

- Transport Package:Standard Export Package

- Specification:to be determined after finalizing with customer

- Trademark:SHJUMP

- Origin:Shanghai, China

- HS Code:8435100000

- Production Capacity:20 Sets ,Year

=== Description ===

Product

Procedure

Fresh fruit, whole

Careful selection with refrigerated holding

Fresh peeled and cored

Refrigerated cylinder, slices, or spears

Whole slices

Frozen or thermally processed in No.21/2 to No.1 cans

Spears and chunks

Odd or broken rings, frozen or thermal processed

Crush

Eradicator flesh, frozen or thermal processed

Juice

Canned single strength or frozen concentrate

Vinegar

From combined process waste streams

Stems

Bromalain

The pineapple thus goes from intact fruit to at least five separate product streams within several minutes in a high throughput, labour efficient, capital intensive system. Many pineapple cultivars are ideally suited for juice, including some with exceptional flavour, but lighter in colour than the typical "pineapple yellow" of `Smooth Cayanne'. Of course, odd sized, noncylindrical-shaped cultivars and fruit with deep seed pockets are not amenable to a Ginaca machine. In these cases, other mechanical or even hand peeling/coring devices are used. Yet, given the commercial effectiveness of ginaca type operations, it is hard to compete with anything less than a highly mechanized operation.

Thorough comminution of pineapple flesh and cores followed by passing the slurry though finishers with ~0.5 to 1-mm screens produces a pulpy juice of 12 to 15ºBrix and °Brix/A around 20. Decanting centrifugation then adjusts the pulp (insoluble solids) level to 12 to 24 percent (Hooper, Ashurst, 1995).

Pineapple juice with a pH of ~3.5 can tolerate moderate thermal processing. A fill temperature of 70ºC followed by rapid heating to 95ºC or a hot fill at ~90ºC with rapid cooling in both cases maintain quality. Major quality defects are: excessive heating or slow cooling, resulting in a dark, scorched juice; too little or too much pulp creating a thin or thick consistency; excessive shell material yielding dark specks and harsh flavour. Home or village processing operations exist where under/over ripe or spoilt fruit are juiced with poor results. The juice can be concentrated to 72ºBrix with or without essence recovery and add-back. The frozen concentrate has a global market as reconstituted juice or a major blending stock. Pineapple is either the base or component of many juice and beverage blends. The trade demands a bright yellow colour, however, some pale yellow, even whitish-fleshed cultivars, when fully ripe can have an excellent flavour, although only appreciated locally.

Despite the impressive efficiency and automation of all pineapple operations, from production through juice processing and shipping, competitive pressure from low labour and land cost Pacific Rim countries have largely decimated the Hawaiian pineapple processing industry. Since the early 1960s when Ginacas and other high throughput equipment became available outside the United States, efficient, low cost producers have captured the majority of global markets for processed pineapple.

These lines rapidly replaced hundreds of workers manually performing mundane preparation steps. Migration of the Hawaiian pineapple industry and ongoing shifts of citrus processing from Florida to Brazil and elsewhere serve as both an inducement and challenge to entrepreneurs interested in exploiting a region's juice potential. Given an adequate infrastructure, sufficient capital and skilled labour, developing regions can compete effectively against industrialized countries, but so can their evolving competitors.

2. Running stably with low noise, speed adjustable by transducer.

3. Anticorrosive bearings, double sides seal.

2 Special design of surfing and bubbling to ensure a through cleaning and lessening the damage to the fruit as well.

3 Suitable for many kinds of fruit or vegetables, such as tomatoes, strawberry, apple,mango,etc.

Our Advantages----Turnkey solution:

No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop service, including your warehouse designing (water, electricity ,steam channel distribution) , staff training, whole line installation and debugging etc.

A-Z SERVICE:

# Consulting + Conception

As a first step and prior to project implementation, we will provide to you profoundly experienced and highly competent consulting services. Based on an extensive and thorough analysis of your actual situation and requirements we will develop your customized solution(s). In our understanding, customer-focused consultation means that all steps planned - from the initial conception phase to the final phase of implementation - will be conducted in a transparent and comprehensible manner.

# Project Planning

A professional project planning approach is a prerequisite for the realization of complex automation projects. On the basis of each individual assignment we calculate time frames and resources, and define milestones and objectives. Due to our close contact and cooperation with you, in all project phases, this goal-oriented planning ensures the successful realization of your investment project.

# Design + Engineering

Our specialists in the fields of mechatronics, control engineering, programming, and software development closely cooperate in the development phase. With the support of professional development tools , these jointly developed conceptions will then be translated into design and work plans.

# Production + Assembly

In the production phase, our experienced engineers will implement our innovative ideas in turn-key plants. The close coordination between our project managers and our assembly teams ensures efficient and high-quality production results. After the successful completion of the test phase, the plant will be handed over to you.

# Integration + Commissioning

In order to reduce any interference with associated production areas and processes to a minimum, and to guarantee a smooth set-up, the installation of your plant will be conducted by the engineers and service technicians who have been assigned to and accompanied the individual project development and production stages. Our experienced staff will ensure that all required interfaces work, and your plant will be successfully put into operation.

**Thoughtful After-sale services:

1). We make accurate factory layout design according to customer's factory size; if the customer needed, we could make workshop design.2). After receiving firm order and down payment, we start to apply for the Visa to your country immediately; while the machines arrives your factory, our engineers are ready to start for the commissioning service.

3). 1-2 of our engineers will go to your factory to install and adjust the processing line to realize normal production at shortest time.

4). Our engineers have responsibility to teach the workers how to operate, clean, maintain and repair all the machines, until the workers could well operate the processing line.

5). Our engineers can provide basic formula for the production, and help the customer to produce good quality food according customer's detailed formula

6). It normally costs 10-14 days for the commissioning service, and we supply 1 year guarantee from the date of completion of commissioning service.

About Us:

Shanghai Jump company professional keeping leadership position in fruit juice & frui jam processing line and machinery. We also have made brilliant achievements in other fruit& vegetable beverage equipments, such as:

1. Juice production line for orange juice, grape juice, jujube juice, coconut drink/coconut milk, pomegranate juice, watermelon juice, cranberry juice, peach juice, cantaloupe juice, papaya juice, sea buckthorn juice, orange juice, strawberry juice, mulberry juice, pineapple juice, kiwi juice, wolfberry juice, mango juice, sea buckthorn juice, exotic fruit juice, carrot juice, corn juice, guava juice, cranberry juice, blueberry juice, RRTJ, loquat juice and other juice drinks dilution filling production line.

2. Can food production line for canned Peach, canned mushrooms, canned chili sauce, paste, canned arbutus, canned oranges, apples, canned pears, canned pineapple, canned green beans, canned bamboo shoots, canned cucumbers, canned carrots, canned tomato paste, canned cherries, canned cherry

3. Sauce production line for mango sauce, strawberry sauce, cranberry sauce, canned hawthorn sauce etc.

We grasped proficient technology and advanced biological enzyme technology, successfully applied in more than 120 domestic and foreign jam &juice production lines and we has helped client gain excellent products and good economic benefits.

Contact Us:To get more information of apple production line, please feel free to contact our engineer:

Cell/WA/VB: 0086 15901792807

More pictures/vedios and detailed proposal will be offered.

Kind reminder to dear customer before contact:please kindly understand that the production line is a highly customized product. Our company is capable to design a processing line with capacity 10T-1500T per day. The machine configuration also will be varied based on the automation degree and the final products type you want to get.Therefore,If you need a quotation proposal from us, please contact our staff and offer the following data to serve you better:>1.What's the estimated capacity? Namely,how many pineapple will be processed hourly? >2.What is final package you want to use----glass/PET/can/bulk pack ?

>3.Will this project be cost-oriented or quality-driven?

We are your best choice for pineapple processing in Turnkey Solution!

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23