304 316 Stainless Steel Jacket Syrup Honey Emulsifying Mixing Tank for Factory

NINGBO HAISHU JUDIN PACKING PRODUCTS CO., LTD. / 2022-07-05

- After-sales Service:Online Service

- Warranty:One Year

- Usage:Biscuit, Cake, Pizza, Bread, Milk Industry

- Power Source:Gas

- Timing Device:Without Timing Device

- Type:Mixer

=== Base Info ===

- Model NO.:KQ Series

- Voltage:All

- Customized:Customized

- Name and Description:304 316 Stainless Steel Jacket Syrup Honey Emulsif

- Material:Stainless Steel 304 , 316

- Agitator Speed:36rpm, 48rpm, 960rpm ,2900rpm

- Function:Storage ,Heaing Mixing

- Motor Brand:Siemens , ABB

- Wall:Single Wall ,Jacketed

- Wheel:Yes , No

- Heating:Electric ,Steam,Gas

- Electronic Box:Yes

- Manway:350mm , 400mm ,450mm

- OEM:Yes

- Certification:CE & ISO

- Insulation Wall:Rock Wool , Polyurethane Foam

- Working Life:10 Years or More

- Delivery:15 Days

- Transport Package:Standard Export Wooden Box

- Specification:ISO

- Trademark:KQ

- Origin:Wenzhou China

- HS Code:8479820090

- Production Capacity:200L To3000L

=== Description ===

Basic Info.

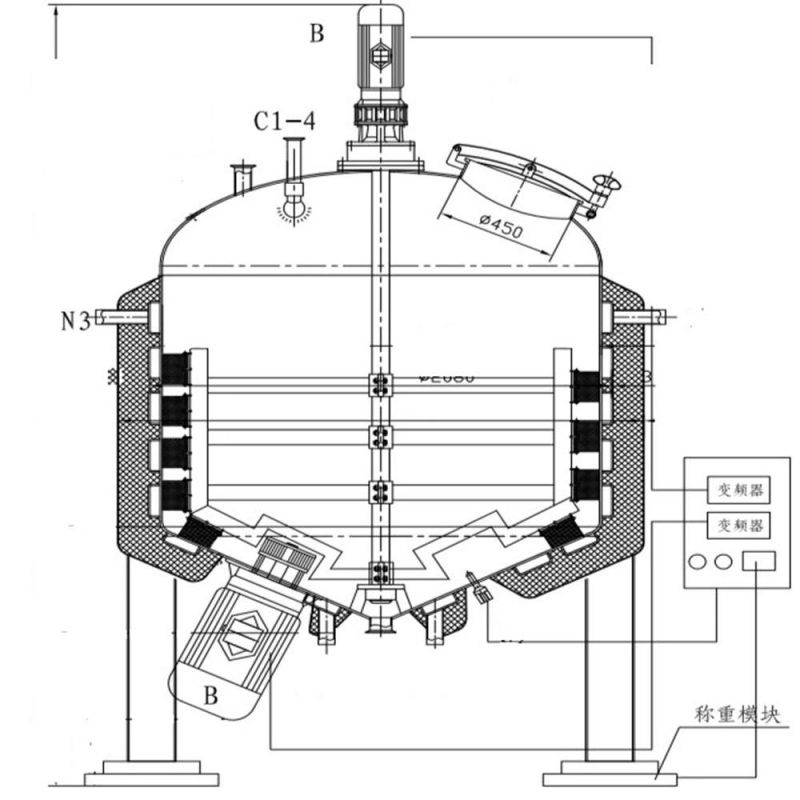

Model NO. KQ Series Voltage All Customized Customized Name and Description 304 316 Stainless Steel Jacket Syrup Honey Emulsif Material Stainless Steel 304 / 316 Agitator Speed 36rpm, 48rpm, 960rpm ,2900rpm Function Storage ,Heaing Mixing Motor Brand Siemens / ABB Wall Single Wall ,Jacketed Wheel Yes / No Heating Electric /Steam/Gas Electronic Box Yes Manway 350mm / 400mm /450mm OEM Yes Certification CE & ISO Insulation Wall Rock Wool / Polyurethane Foam Working Life 10 Years or More Delivery 15 Days Transport Package Standard Export Wooden Box Specification ISO Trademark KQ Origin Wenzhou China HS Code 8479820090 Production Capacity 200L To3000LProduct Description

304 316 Stainless Steel Jacket Syrup Honey Emulsifying Mixing Tank for Factory .

| 1 | sugar mixing tank |

| TankCapacity(L) | 200, SS304 | 300, SS304 | 500, SS304 | 1000,SS304 |

| REV | 36r/min | 36r/min | 36r/min | 36r/min |

| Electric motor of the agitator | 0.55KW,380v,50hz | 0.75KW,380v,50hz | 0.75KW,380v,50hz | 1.1KW,380v,50hz |

| Heating Area(M2) | 0.9 | 1.1 | 1.9 | 4.5 |

| Material Input/output(DN MM) | 38 | 38 | 38 | 50 |

| OUTSIDE DEMENSION(L*W*H)MM | 900*900*1600 | 1000*1000*1500 | 1100*1100*1700 | 1400*1400*1750 |

| GROSS WEIGHT(KGS) | 150 | 200 | 300 | 450 |

steam vessel 500 litres

Material: Ss304

* Type: With Jacket and insulation

* Internal shell thickness: 3 mm

* Jacket thickness: 3 mm

*PU INSULATION WALL: 50MM

* Outer shell thickness: 1.5 mm

* Appearance: Ellipsoidal head top and down manhole and pipe will be as the picture you sent to us

* Accessories:

(1) Manhole covers

(2) Charging/discharging hole at the bottom,

(3) CIP Cleaning ball

(4) Steam heating tube

(5) Rack & blender etc.

(6) the electric motor

Agitator blending tank

1. More than 10 years experience

2. Capacity: 100-5000L

3. Manufacturer

4. Custom-made solution

Steam heating chemical agitator tank blending tank

PME Multi-function Blending Reactive Mixer/ vacuum homogenizer mixer

High speed disperser, might mixing and disperse viscously. Solid and liquid raw material can dissolve material which is hard to dissolve such as AESAESALSA during liquid production which can save energy consumption and shorten production period.

Main blender adopts stepless speed variator device and under low temperature and high viscosity condition, less air bubble will be formed;

It is suitable to produce liquid washing products;

It can give out material directly or matched with screw pump.

Double wall steam heating tank

Le-layer tanks are widely applied in the beverage, food, dairy, pharmaceutical, chemical and process indusries used as blender tank, buffer tank, and storage tank, which cleanable to sanitary standards.

Doublewall steam heating tank configuration:

Manhole

CIP cleaner

Adjustable trangle bracket

Ladder

The rmometer

Liquid lever meter and controller

Eddy-proof board

Dismountable inlet assembly

Sanitary breathing cover

Specifications

We can supplies single-layer, dual-layer, and three-layer stainless tanks with or with out agitation to blend product.

Specifications

Product name: Blending tank / Mixing tank

MOQ: 1 set

MOC: Stainless steel grade 304/306L

OEM experience: 30yea

Product Name

Vertical mixer, Blending tank, Mixing vessel

Applicable range:

1. Used as liquid storage tank, liquid composing tank, temporary storage tank and liquid blending tank etc.

2. Ideal in fields such as foods, dairy products, fruit juice beverages, pharmacy, chemical industry and biological engineering etc.

Structure characteristics

1. Adopt structure of internal tank and external package, with heat preservation materials inside.

2. Materials are all sanitary stainless steel.

3. Humanized structure design and easy to operate.

4. Transition area of interior wall on tank adopts arc for transition to ensure no dead comer of sanitation.

Configuration of tank

1. Quick open manhole.

2. Various types of CIP cleaners.

3. Fly and insect resistant sanitary breathing cover.

4. Adjustable triangular bracket.

5. Dismountable materials input pipe assembly.

6. Thermometer (According to customer requirements ).

7. Ladder (According to customer requirements).

8. Side blender.

9. Liquid level meter and lever controller (According to customer requirements).

10. Eddy-proof board.

Remarks

RemarksIt can be made according to special requirements of customers.

304 316 Stainless Steel Jacket Syrup Honey Emulsifying Mixing Tank for Factory .

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23