High Quality Planetary Kneading Dough Mixer Cream Whisk Dough Mixer 50kg

Suzhou Texnet Co., Ltd. / 2022-07-05

- After-sales Service:Free Spare Part

- Warranty:Free Spare Part

- Usage:Pizza, Bread, Dough Mixing

- Power Source:Electric

- Timing Device:With Timing Device

- Type:Mixer

=== Base Info ===

- Model NO.:LY-50

- Voltage:220V

- Customized:Customized

- Transport Package:CTN

- Specification:78*61*74CM

- Trademark:za

- Origin:China

- HS Code:8438100090

- Production Capacity:900000,M

=== Description ===

Basic Info.

Model NO. LY-50 Voltage 220V Customized Customized Transport Package CTN Specification 78*61*74CM Trademark za Origin China HS Code 8438100090 Production Capacity 900000/MProduct Description

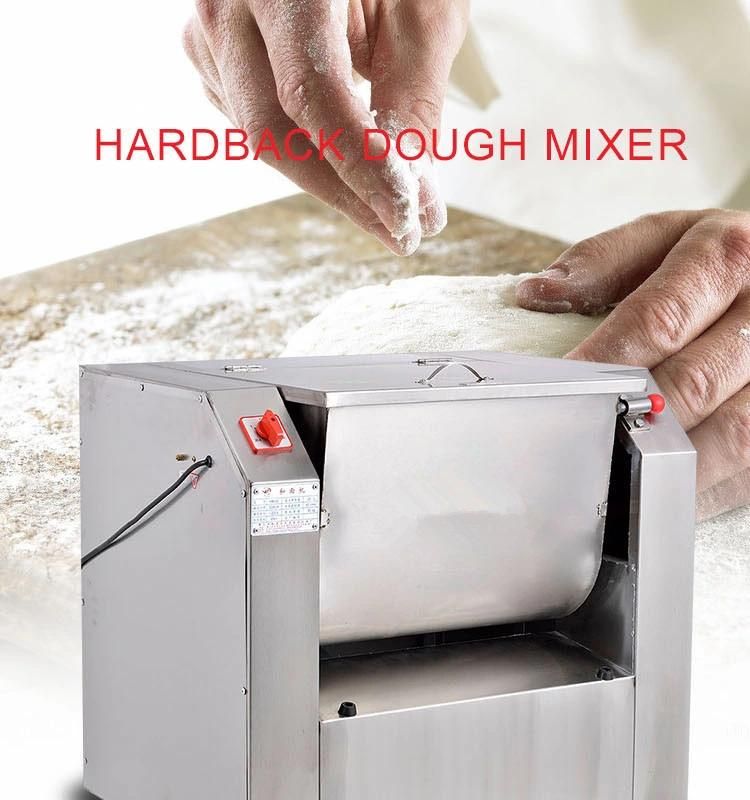

high efficiency dough rolling moulding machine Dough Kneader Stirring Mixer for Home Commercial Use

This series of dough mixer are used in restaurants, enterprises, institutions, and food processing plants for making steamed buns, biscuits, fried dough sticks, buns, snacks, biscuits, bread, cakes, etc. The machine has the characteristics of low noise, high work efficiency, compact structure, flexible and simple operation, uniform mixing and convenient maintenance.

Installation and use:

1. Check whether the fasteners of each part of the machine are loose, if they are loose, they need to be tightened.

2. Place the machine on a level ground that is not easily accessible to others.

3. The grounding mark at the lower part of the machine must be reliably grounded to prevent leakage of electricity and hurt people.

4. The user prepares all-pole disconnecting device (such as a knife switch) to connect the machine cable.

5. Close the knife switch and move the switch handle to make the machine test run. The machine can be put into use without abnormal noise.

Operating procedures:

1. Stirring: Pour the flour into the kneading bucket first, add 50% water to stir, and stir for about 5 minutes to make up. For example, when the dough and the mixer turn together, sprinkle some dry flour to eliminate it. When the machine is running normally, the steering of the auger should be consistent with the arrow on the belt guard.

2. Take the noodles: After the noodles are reconciled, disconnect the power, open the cover, pull out the latch, turn the noodle bucket 90 degrees, insert the latch to fix the noodle bucket, and take the noodles. If the dough is too large, use a knife to cut the dough into pieces and take it out. If the dough at the bottom of the noodle bucket cannot be taken out, you can turn the dough out to take out the dough.

Maintenance procedures:

1. Frequently check the fasteners of various parts during use, and tighten them in time if they are loose;

2. The gear meshing area of this machine is lubricated with grease, and the oil is added once every half a month. There are powder metallurgy bearings in the bearing housing. The oil cup on the bearing housing must be filled with oil twice per shift, otherwise the shaft and bearing shells will be glued at your own risk;

3. The amount of flour added when mixing the noodles should not exceed the capacity of the noodle bucket, so as not to burn the motor;

4. If oil is found on the dough, it should be repaired in time and the oil seal should be replaced.

Cleaning:

1. The machine should be cleaned in time after use, so as not to affect its reuse;

2. When cleaning, the height of water in the noodle bucket should not exceed the lowest point of the shaft to prevent water from overflowing from the shaft hole of the side plate of the noodle bucket or flowing into the side plate interlayer and affecting the service life;

3. This machine is a drip-proof appliance, and it is forbidden to clean it with a water spray pipe.

Packaging & Shipping

Packaging & Shipping• All Machine will be cleaned and whole wraped by plastic film to avoid any scratch;

• Extra Spare Parts,wires and tool box will be placed with the package;

• Delivery Department and sales will check the list to avoid any missing;

• All foam+carton packing for protecting the machine during long-time shipment;

FAQ

• 1 Where is your factory?

• guangdong Province, China

• 2 What is your machine warranty?

• 1 year, main parts warranty time will be 1 years.

• 3 Do you supply spare parts?

• Yes, we supply spare parts with reasonable price;

• 4 What can you provide for after sale service?

• on line support ,video support and We can send engineers to your factory for installation and training if customers' required.

• 5 If we show you our layout of factory, can you help to design the whole process line?

• Yes, our experienced engineers and technical employee can help you to arrange the layout and installation of whole process line based on your real situation;

• 6 How can we contact you if we meet problems during production?

• Phone/email/wechat/whatsapp/Skype are all available.

• 7 If we have samples of new products, can you help to analysis and design the machine?

• Yes, Our technical department can help to analysis, design and test the new products you offered.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23