Large Scale Full Automatic Coconut Milk Processing Line Coconut Cream Processing Line ...

Nanjing Lipack Import and Export Co., Ltd. / 2022-07-05

- Type:Food Processing Line

- Voltage:380,415,450V up to Different Nation

- Power:180-380kw up to Capacity and Configuration

- Customized:Customized

- Machine Raw Material:SUS304,SUS316,Titanium

- Degree of Automation:High or to Be Customized

=== Base Info ===

- Model NO.:LRY-JP

- Products Type (Brix):8%|16%|32%|40%|48%|56%|72% to Be Defined

- Products Package:Can, Bottle, Pouch, Pet, Aseptic etc.

- Compatibility & Expandability:Excellent

- Transport Package:Standard Export Package

- Specification:125kg-125tons per hour

- Trademark:SHJUMP

- Origin:Shanghai, China

- HS Code:8435100000

- Production Capacity:23

=== Description ===

No.

Process Section

Main Process

1

Cleaning and picking

raw material collection, cleaning, sorting, etc.

2

The crushing and pulping

crushing,juicing,enzyme inactivation, pulping, etc.

3

Biochemical refining

including enzymatic hydrolysis, fermentation, filtration, concentration evaporation,blending, degassing, homogenization, etc.

4

Sterilization filling

including UHT sterilization, filling, post pasteurization, etc.;

5

Finished product packaging

including light inspection, drying, labeling, sleeve label shrinking, coding, boxing, sealing, wrapping, palletizing, etc.

2.2 Solid state product form

Dried fruit processing and fruit powder processing production lines can be roughly divided into the following process sections

2.3 Main equipment list

Main Equipment

Function

Elevating Machine

Material's lifting and preliminary washing

Shell Crushing& water extract

Shell Crushing& water extract

Washing Machine

Meat washing

Sorting Machine &Crushing Machine

crushing the meat

Pre-heater

Material's pre-heating, enzyme deactivation and color protection

Pulping &juicing machine

extract the juice

Vacuum Evaporator

Water's evaporation and concentration of juice/pulp

Sterilizer

Sterilize the material by heat-treatment

Aseptic Filler

Fill the materials into bag-in-box and bag-in-drum aseptic bag

Conveyor

Transport the material or final products

Centralized control cabinet

PLC human-machine interface, equip with manual or automatic operation

2.4 Detailed consultation

Successful production lines are not exactly the same;

Failed production lines are all the same!

The process route and process flow involve the core technology of the production line, and the whole or part process route, raw material resources, product positioning, market channels and investment strategies are all different. The above process route is for reference only, and the process execution route shall be subject to the actual raw materials and product form requirements.

Detailed information please contact Roy Li

Food engineering expert (with practical engineering experience in more than 300 fruit and vegetable processing and plant extract processing production lines in the world)

3 Production Site Show

*************************************************************************

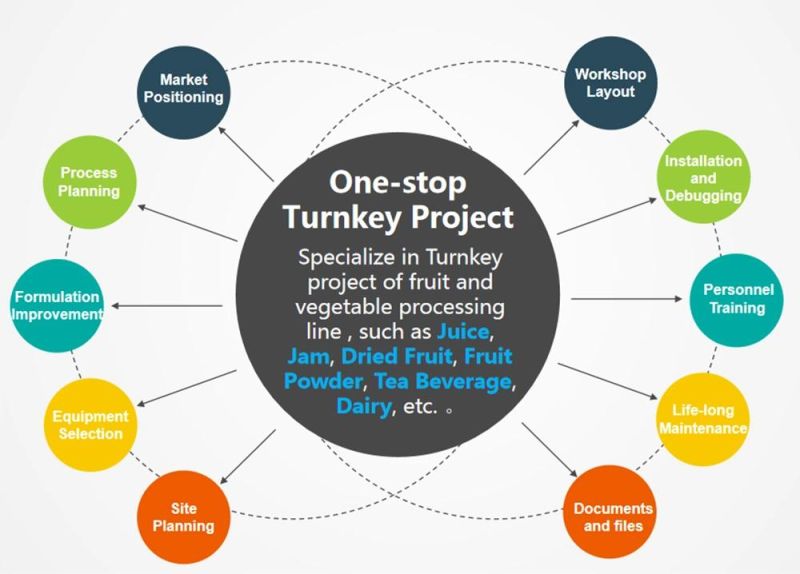

4 Our Advantages

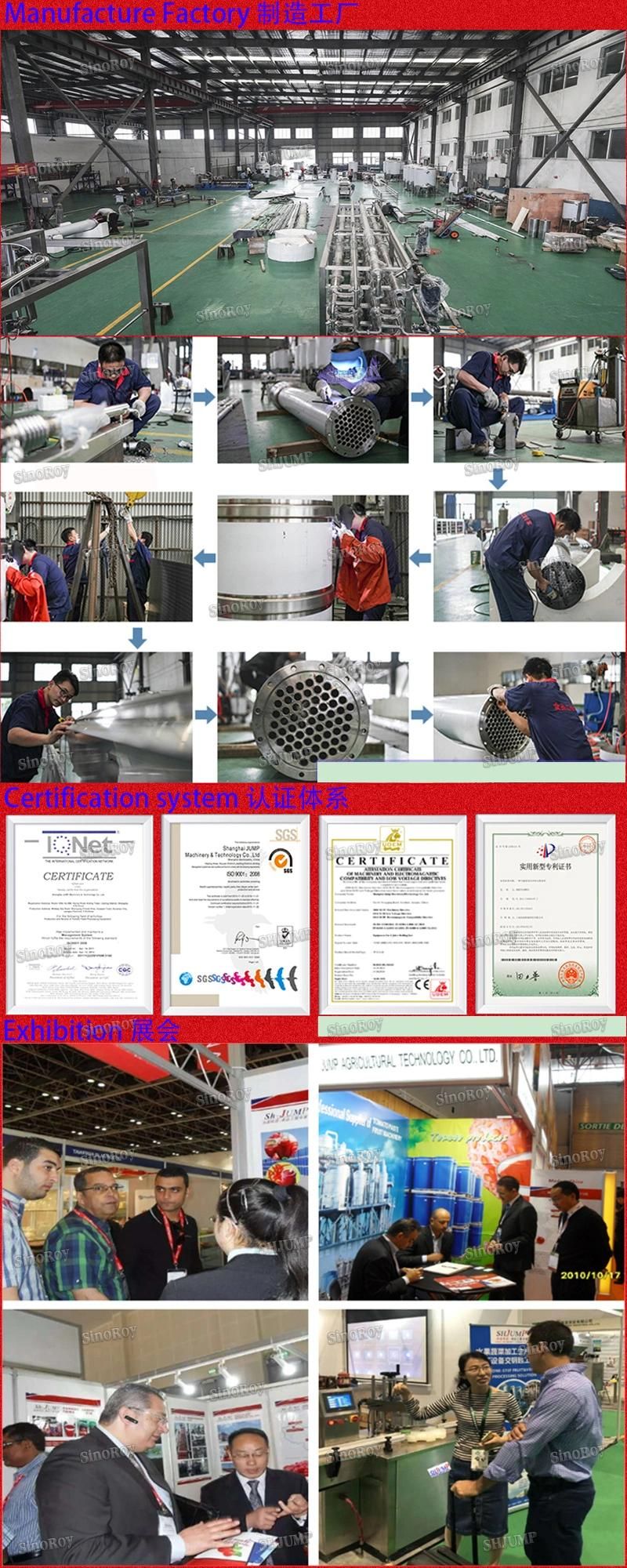

5 Introduction of SHJUMP

Company Show of Shanghai Jump Machinery & Technology Co., Ltd.

*************************************************************************

6 Contact Information

Over 300 fruit juice, jam, preserved, fruit powder, fruit oil, wine, and vinegar plant extracts processing production lines, food engineering experts

Company Name: Shanghai Jump Machinery Technology Co., Ltd.

Roy Li +86 ▓ 139 ▓ 1815 ▓ 9786

Roy Li +86 ▓ 133 ▓ 1005 ▓ 6505

Manufacturing plant address: Shanghai Jump Machinery & Technology Co., Ltd. , 58 Pengqing Road, Kunshan City, Jiangsu Province,China.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23