10 mm Thickness PVC Twin Wall Solid Hard Hollow Core Plastic Sheets Extrusion Machine

Fujian Quanzhou Huazuan Diamond Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. ACEMIEN-1050 Customized Customized Condition New Transport Package Plastic Film Package and Loaded Into The Container Specification 28m*5m*5m Trademark Acemien Origin Jiangsu Province HS Code 84772090 Production Capacity 1000 Sets/YearProduct Description

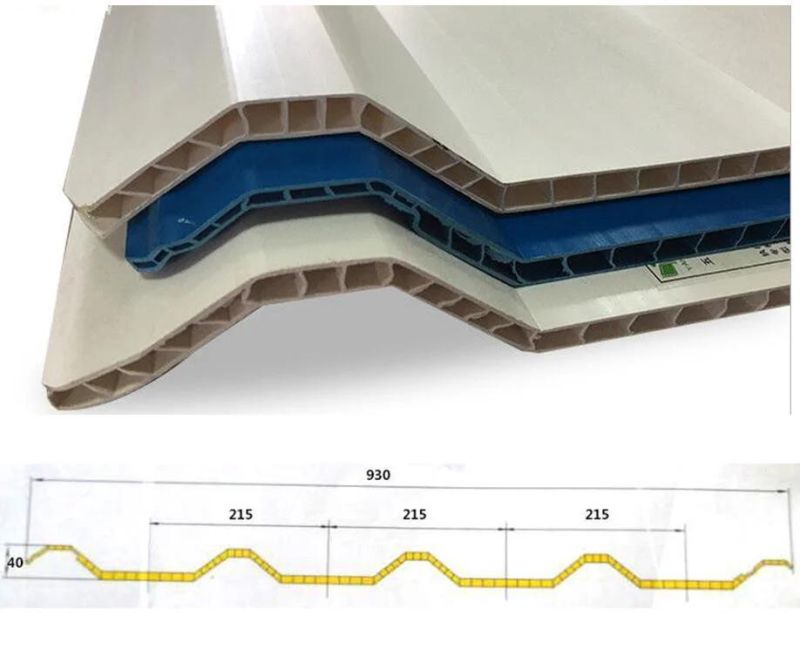

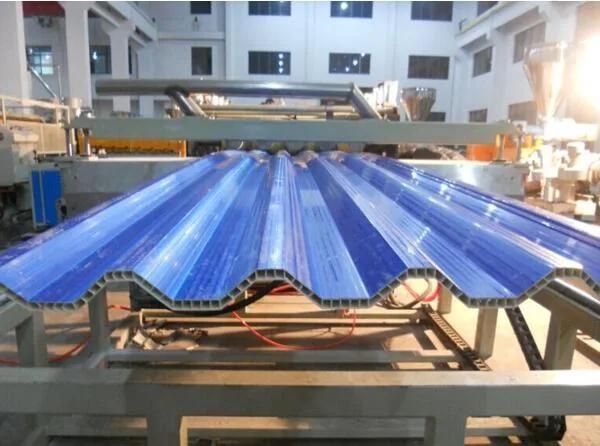

10 mm thickness Pvc Twin Wall Solid Hard Hollow Core Plastic Sheets extrusion machineThe 10 mm thickness Pvc Twin Wall Solid Hard Hollow Core Plastic Sheets extrusion machine can produce the corrugated roofing sheet, and the roofing sheet 1.5-4.0mm, Output:350-400kg/h(Depending on CaCO3 proportion).

The raw material is : PVC powder, CaCO3, CPE, PE-WAX, Stearic acid , Compound stabilizer ,ACR, paraffin,ASA granule.

The 10 mm thickness Pvc Twin Wall Solid Hard Hollow Core Plastic Sheets extrusion machineinlucing below parts:

Screw loader for SJZ 80/156 extruder

SJZ 80/156 conical twin-screw extruder(PVC)

Vacuum loader and drying hopper

SJ50/30 single screw extruder(ASA)

Extrusion mould and distributor

Forming table

Haul off unit, 6 stations of haul off rollers.

Cutter, the cuttig method is pneumatic saw cutting, the tracking cutting method.

Stacker, the normal receiving table is 3 meters/2 sets.

This is the haul off unit of 10 mm thickness Pvc Twin Wall Solid Hard Hollow Core Plastic Sheets extrusion machine

There are 6 teams of stations of the rollers which is with the fuction of the hauling off.

This is the cutting system of the 10 mm thickness Pvc Twin Wall Solid Hard Hollow Core Plastic Sheets extrusion machine

This is the receiving table of the 10 mm thickness Pvc Twin Wall Solid Hard Hollow Core Plastic Sheets extrusion machine

If you need this 10 mm thickness Pvc Twin Wall Solid Hard Hollow Core Plastic Sheets extrusion machine or you are interested in this Two-layers Hollow Corrugated PVC Roof Tile Production Line plasic extrusion machine.

please feel free contact me please.

My name is Karry, please feel free contact me, please!

Phone: +86 18205059535

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23