PP PE WPC Decking Profile Extrusion Machine WPC Profile Board Making Machine Line

CHINA GTL TOOLS LIMITED / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJSZ65/132 Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Extruder Type Conical Twin Screw Extruder Plastic Machine Name WPC Wood Plastic Profile Machine WPC Application Decking Profile, Ceiling, Wall Panel, Door Window Raw Material PE, PVC, etc+Wood Owder+ Chemicals Intelligent Temperature Controller PLC with Pid Control From Japan Omron Brand Low Voltage Appliances Siemens Brand Button, Contactor,etc From France Te Screw Material 38crmoala Nitriding Motor AC, 37kw Extrusion Capacity of Extruder Machine 180-250kg/H Transport Package as Export Standard for Plastic Machine Packing Specification CE, ISO9001: 2008, SGS, etc Trademark WEIER Origin China HS Code 84772090 Production Capacity 60 SetsYearProduct Description

PP/PE/PVC WPC wood plastic composite profile extusion machine line---Turn key project with CE certificated most professional wpc machine manufacturer in china

weier series wood plastic composite wpc profile machine production line mainly use pvc/pe recycle+wood powder,

producing skirting, window and door frames, furniture edge, door pocket, decorative profiles, etc. The wpc line use

our original wood plastic technique and formula, design the proportion of different wpc products according to their

different profile section, usage, etc.

Pictures of the machine

1. Equipment list for the wood plastic wpc profile machine1.1 Twin Screw Extruder SJSZ-65, One set 1.2 Vacuum Calibrating Table, One set 1.3 haul-off machine, One set 1.4 Automatic Cutting Machine, One set 1.5 Tilting table, One set 2. Summarization for the wpc wood plastic profile machine2.1 Suitable resin PVC resin+wood powder+additives, as per our special formula 2.2 Line speed Max 4 m/min 2.3 Max output 150 kg/h 2.4 Outer dimension 24 * 1.5 * 2.6 m 2.5 Weight 11 T 2.6 Total power 89 kW 2.7 Power supply 380V± 10%, 50Hz; Controling power supply: 220V± 10%

3. Equipment component for the wpc wood plastic profile machine: (1) conical twin screw extruder SJSZ65/132 (2) extrusion mould for profiles (sample) (3) vacuum sizing platform (4) haul off and cutter (5) reversal stacker (6) door and window profile samples: And other profiles 4. Guarantee: We will realize guarantee of repair; Replacement and refund of substandard products within one year

after the machine arrived in customer's factory (except destroyed by buyers' wrong operation). We

guarantee the material of screw&barrel (guarantee without normal abrasion). And half a year for

electric parts. Fittings of the machine will supply at preferential price after one year.

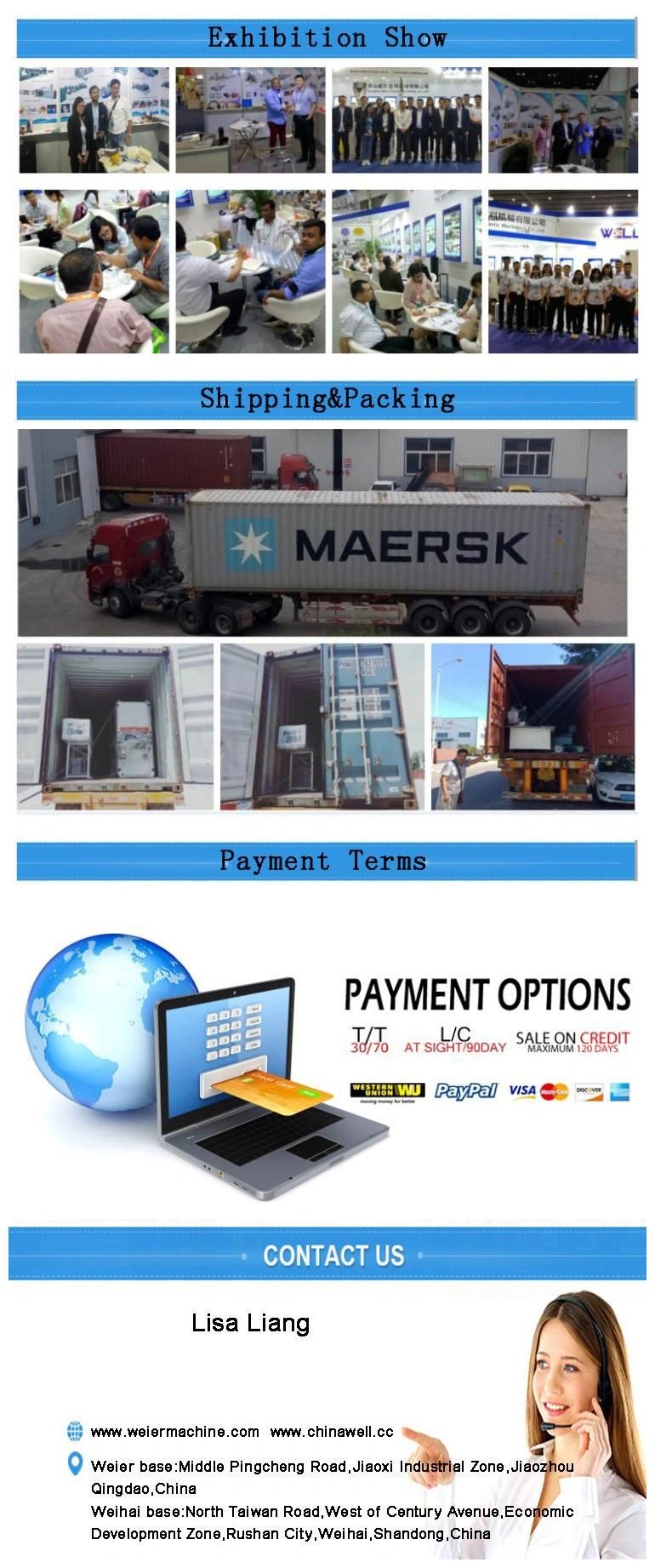

Our factory

Qingdao Weier Plastic Machinery Co., LTD is the director member of WPCC (Plastic &Wood Production

Council of Chinese Plastic Community), now we are Plastic Engineering Technology Research

Institute of Qingdao Science and Technology University Test and Industrialization center. We

cooperated with many domestic universities to develop special plastic machines to meet domestic

and foreign customer's requirement and have a strong association with many macromolecule and

chemical majors of many universities. At the same time we bring in and absorb advanced processing

engineering of foreign plastic machines to realize chain service of technique and machines.

WHY CHOOSE WEIER? (1) we have experiences in this field since 1980s (2) we have our production bases in China, which shows our machine's production power (3) we have strond technical teams and cooperate with China scientific institution to develop, improve and

WHY CHOOSE WEIER? (1) we have experiences in this field since 1980s (2) we have our production bases in China, which shows our machine's production power (3) we have strond technical teams and cooperate with China scientific institution to develop, improve andtest our machine (4) we have perfect service system: Our boss is devoting himself to after-sale service We will provide the Feasibility Analysis Report for the plastic machine project. We will provide the model design for the plastic machine plant and electric power accounting for the facilities. We will provide the model selection and technical parameter for our plastic machine. We will provide plastic formular according to the product requirements. We will provide technique training for operator. We will provide solution for the practical problem during the production. We will install and test the plastic machineand teach customer's workers how to operate in customers' factory. We will provide turn-key project to customers.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23