PE Hollow Wall Winding Pipe Extrusion Making Machine (SJ)

Ningbo Zhaoke Int'l Imp. & Exp. Corp / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJ120 Condition New Material Stainless Steel Power Supply 380V Three Phase Inverter ABB Intelligent Temperature Controller Omron After Sale Service Life Long with Professional Sercive Warranty One Year Raw Material PE Granule Machine Color as Requst Operator 2-5 Per Line Contactor Schneider Transport Package as Export Standard for Plastics Machine Specification CE ISO9001 Trademark SUKE Origin Qingdao, China HS Code 84775900 Production Capacity 30 Set/ One YearProduct Description

PE Hollow Wall Winding Pipe Machine (SJ)MACHINE INTRODUCTION:

The pipe used polyethylene (PE) as the main raw material preliminarily made into "T" shape plate belt and then the belt is wound and welded into pipe. At the same time, make the galvanized steel belt into a "U" shape steel belt and then is embedded into the groove of the two plate belt, then cover the embedded steel belt with PE sheet. This kind of pipe becomes the 3rd new generation of plastic and steel drain pipe.

PIPE FEATRUES:

Advantages of both plastic - corrosion resistance and steel - tenacity. It is strongly recommended as the new type of environment protection drainage pipe by the government.

1. Light weight, easy installation;

2. Well sealed and no leakage;

3. Low cost of transport and construction;

4. Strong corrosion resistance, Strong resistance to abnormal sudden load, etc.

5. Diameter 300-3000 mm

PIPE APPLICATION

Used in city sewage pipeline, industrial sewage pipeline, rainwater drainage pipeline, drainage pipeline for bridge, the agriculture irrigation pipe, water intake pipeline and so on.

It has big market prospects, and it is also the first choice for the important construction engineering projects.

EQUIPMENT LIST:

1. Single Screw Extruder

2. Cooling Water Tank

3. Haul-off Machine

4. Winding Machine

5. Cutting Machine

6. Stacker

TRADE TERMS

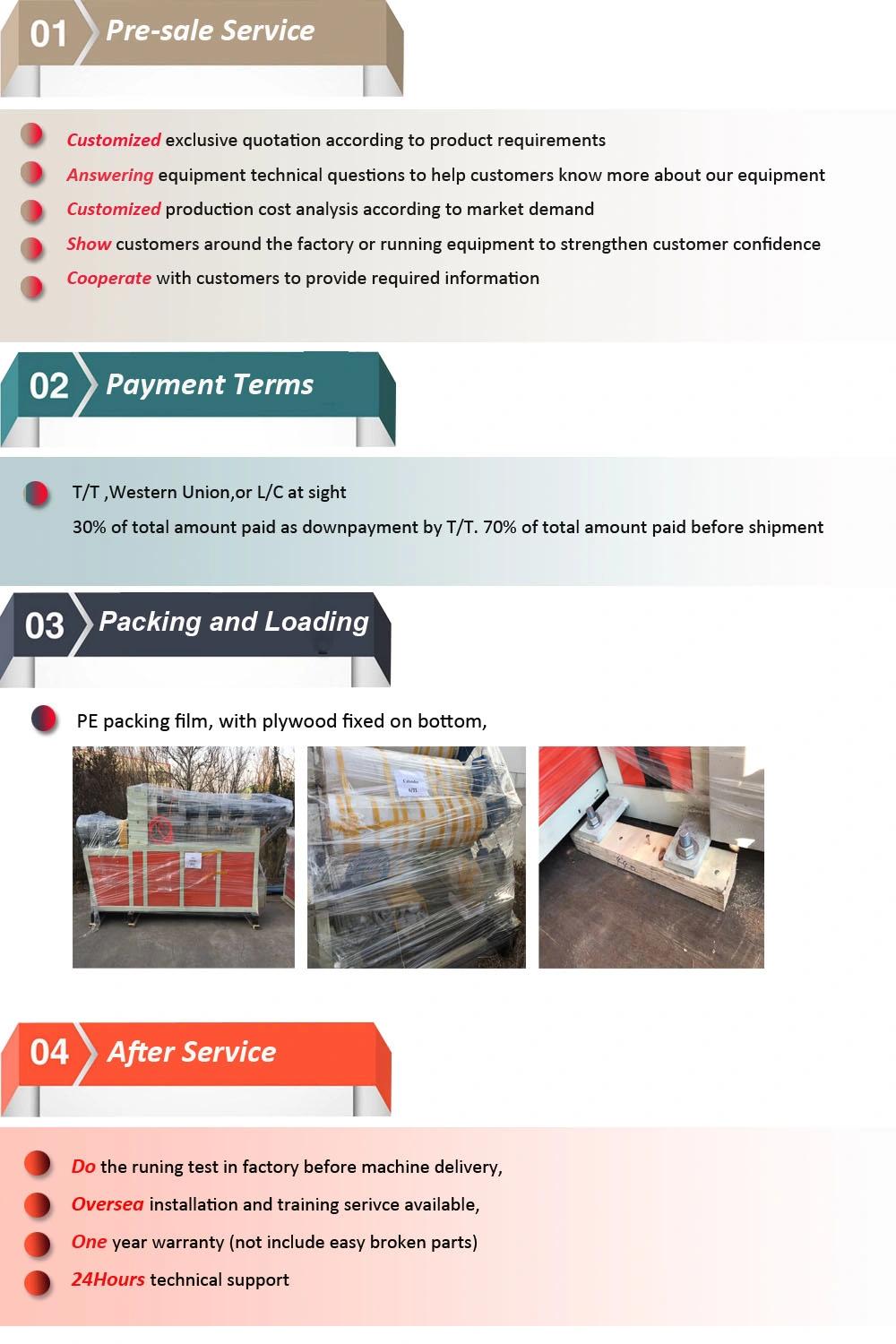

Payment Term: 30% for prepayment by T/T, 70% for balanced payment by T/T, or L/C can be acceptable

Delivery Time: 40 days after receipt of prepayment.

Packing Method: Packing film or wooden case

Guaranteed Time: 12 months

MACHINERUNNING TEST AND AFTER SERVICE

When machine finished, we will invited client come to our factory to check the machine and do the machine test. If machine is ok, then client pay for the balance. And inspect machine load the container.

When machine arrives client's factory, if client needs, we will send 1-2 engineer to client's factory do the machine installation and running test, and also train the local worker how to operate and maintain the machine. It is chargeable.

If have any question or problem on machine operation or maintain, welcome to contact to us by email or calling. We stand by 24 hours.

CONTACT INFORMATION:

COMPANY SHOW

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23